Pneumatic rotary suction nozzle

A rotary and pneumatic technology, applied in the field of pneumatic rotary suction nozzle device, can solve the problems of reducing the reliability of the feeding mechanism, the existence of safety hazards, and the large size of the suction nozzle, so as to simplify the feeding mechanism and its control system, Improve the reliability and safety, the effect of safe and environmentally friendly material transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

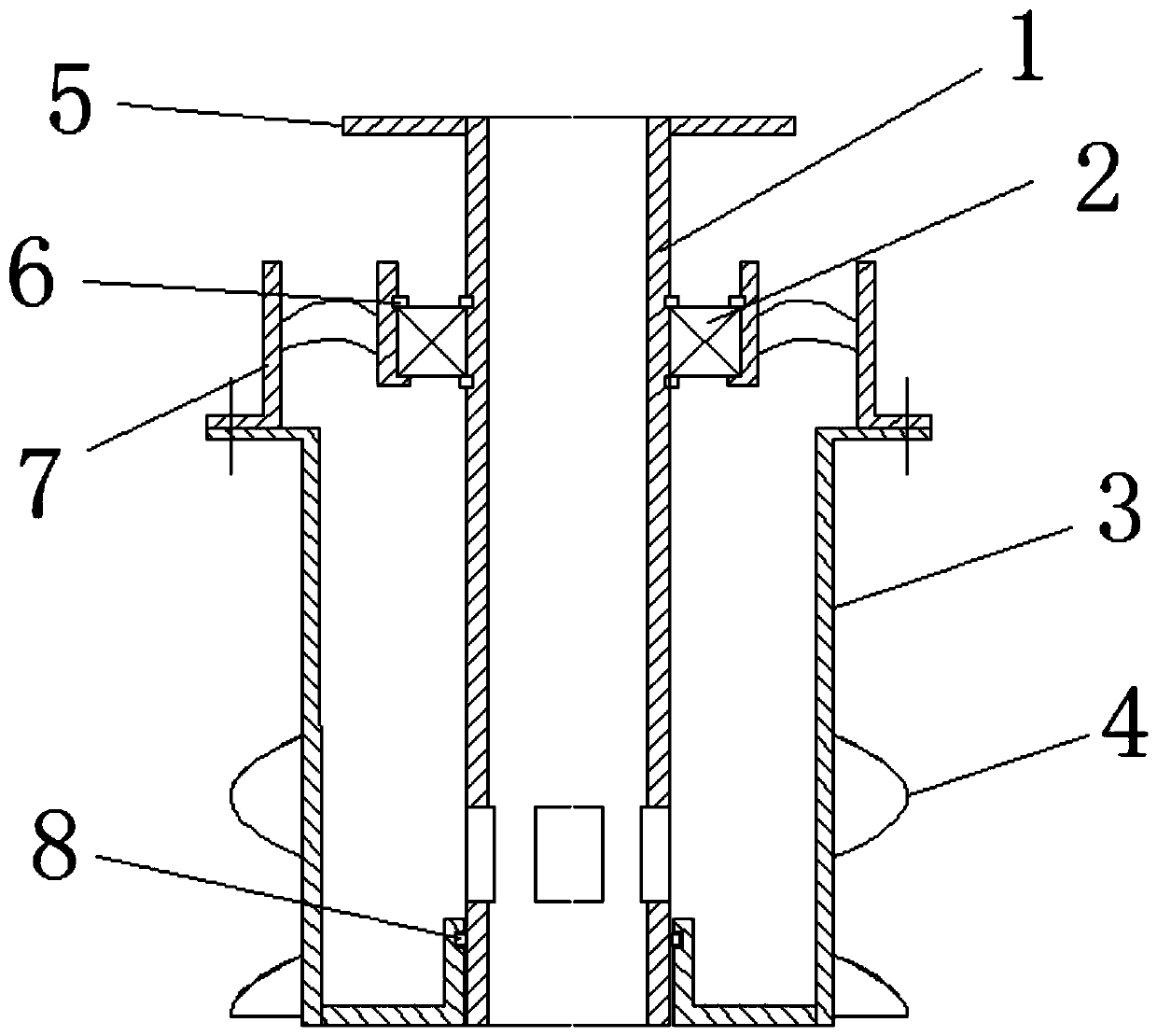

[0009] Such as figure 1 As shown, the inner cylinder (1) and the flange (5) are connected by welding, the turbine blades are welded between the inner and outer cylinders of the turbine (7), and the inner ring of the turbine (7) and the inner cylinder of the suction nozzle are slewing (2) Connect to ensure the rotation of the turbine (7) relative to the inner cylinder (1), the slewing bearing (2) is limited by the bearing stop ring (6), and the outer cylinder (3) and the turbine (7) are connected by screws The fixed connection is connected with the spiral blade (4) and the outer wall of the outer cylinder (3) by welding. Both the turbine (7) and the outer wall of the outer cylinder (3) have a flange structure, and their joint surfaces should be equipped with sealing rings to ensure their airtightness through screw connections.

[0010] When the material is sucked, the air flow enters the outer cylinder from the turbine (7), and due to the action of the air flow, the turbine 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com