Discharging funnel device capable of solving difficult auxiliary material discharging problem

A funnel and blanking technology, which is applied in the field of blanking funnel devices, can solve the problems of reduced material delivery, smaller funnel cross-section, and blocked funnels, so as to improve material fluidity, solve material blocking phenomena, and meet production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with embodiment:

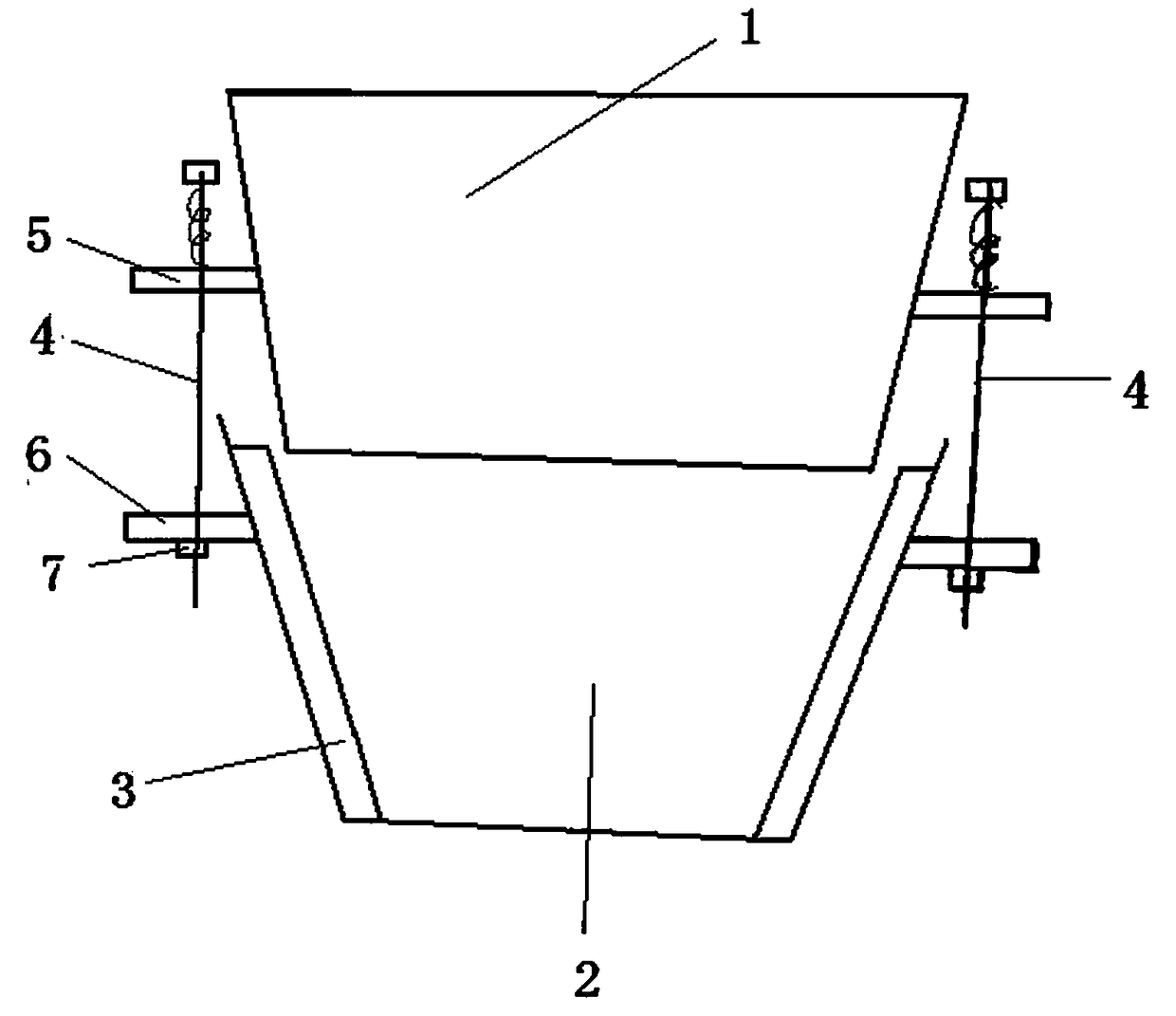

[0012] See figure 1 , is a structural schematic diagram of an embodiment of a feeding funnel device that solves the difficulty of feeding auxiliary materials according to the present invention. The feeding funnel device is divided into upper and lower parts. The corresponding positions of the upper funnel 1 and the lower funnel 2 are provided with fixing seats 5 and 6. The spring connecting rod 4 connects the upper and lower parts together through the opening on the fixing seat, and is fastened with the fixing nut 7, and the inner wall of the lower funnel is laid with an anti-adhesive liner 3 .

[0013] Currently in production, the inner wall of the lower funnel is inlaid with a 10mm thick polymer polyethylene liner with a molecular weight greater than or equal to 3.5 million.

[0014] In addition, other solid waste resources can also use this structure of the feeding funnel device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com