Coal and garbage coupled fuel integrated treatment system and method based on fluidized bed

A comprehensive treatment, fluidized bed technology, applied in the field of coal and garbage coupled fuel integrated treatment system, can solve problems such as poor feeding, burning belts, poor maintenance environment for workers, etc., to increase material fluidity, prevent dust overflow, The effect of reducing water spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

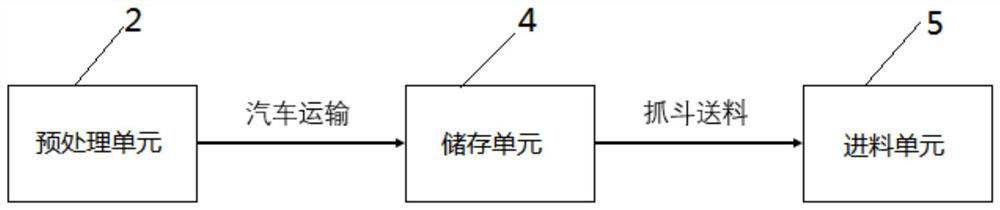

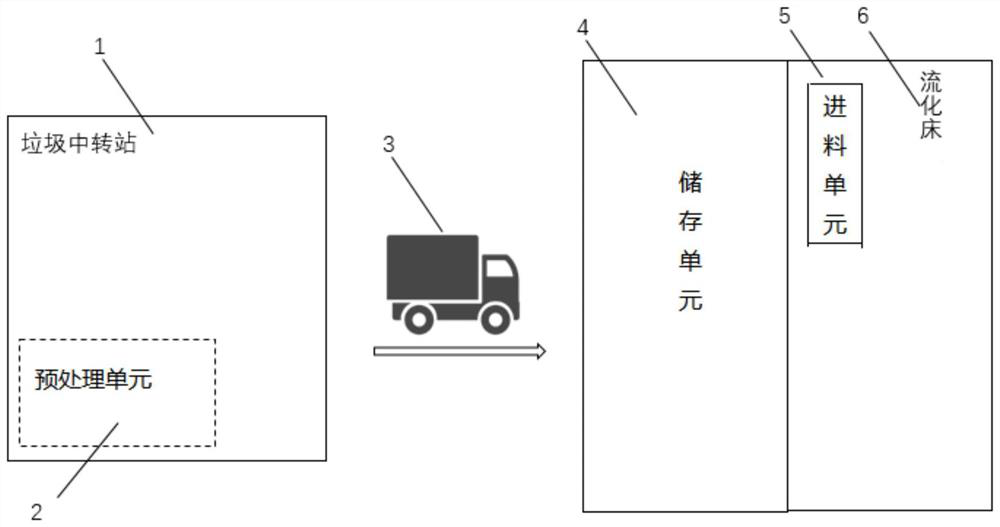

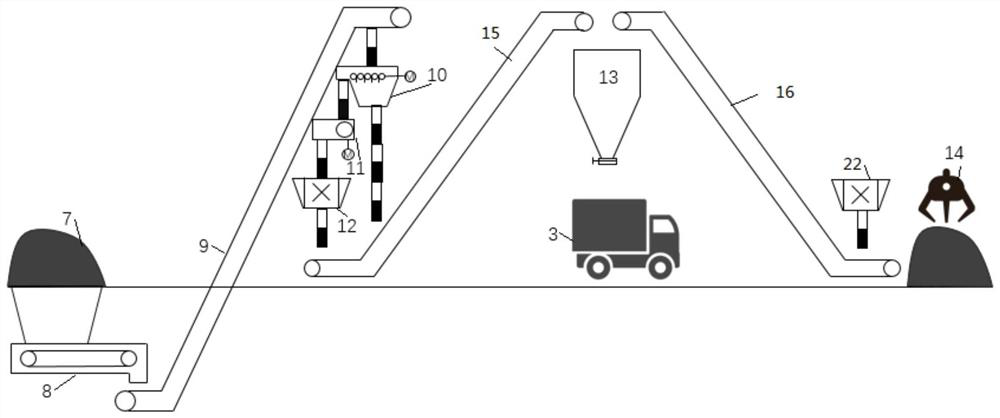

[0039] like figure 1 and figure 2 As shown, the fluidized bed-based coal and garbage coupled fuel integrated treatment system in this embodiment includes a preprocessing unit 2 for coupling raw coal 7 and primary garbage to form a uniformly mixed coupled fuel; a storage unit 4 (such as Material storage pit), used to store the coupling fuel; feeding unit 5, used to transport the coupling fuel in the storage unit 4 to the circulating fluidized bed 6 for combustion; such as Figure 4As shown, the feeding unit 5 includes a grabbing assembly 17, a feeding hopper 18, a pushing assembly 19, a feeding pipe 20 and a coal sowing air assembly 21. The grabbing assembly 17 is located above the storage unit 4 and the feeding hopper 18. The coupling fuel in the storage unit 4 is grasped and transported to the feeding hopper 18 . The butt joint is used to pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com