Blast furnace inclined bridge dismantling method

A technology of inclined bridge and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts and other directions, to achieve the effects of high safety, improved construction efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

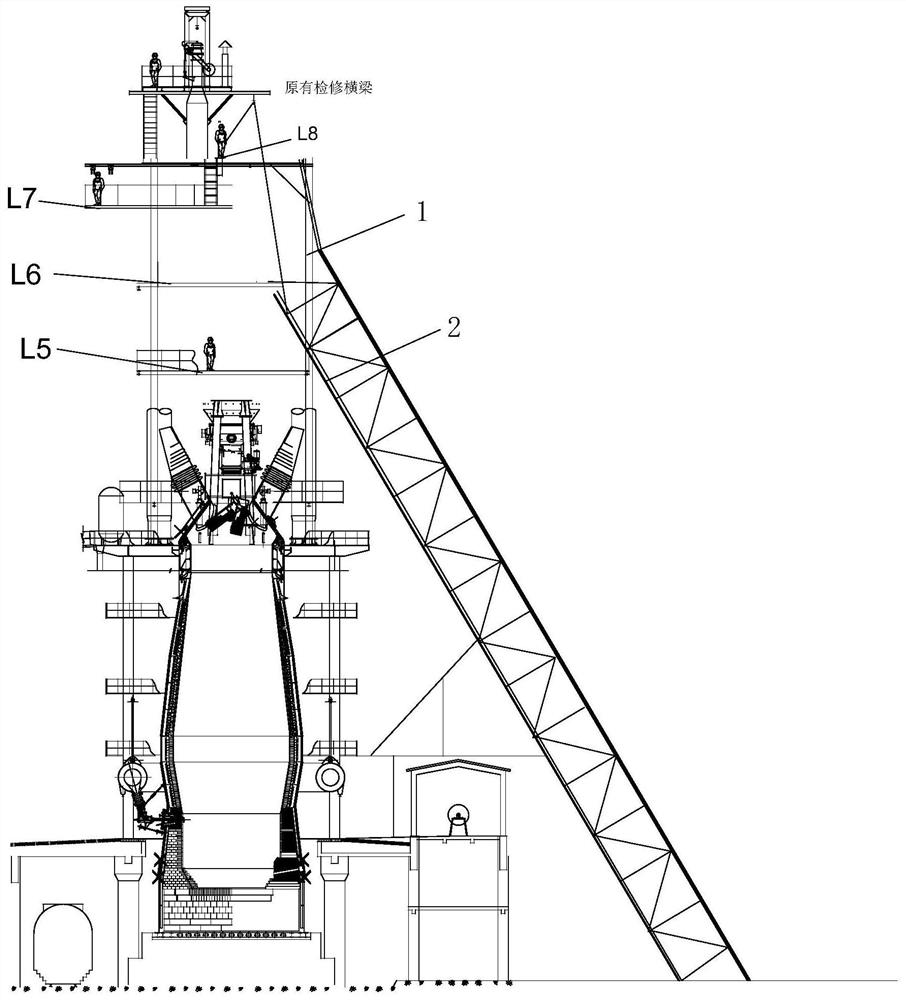

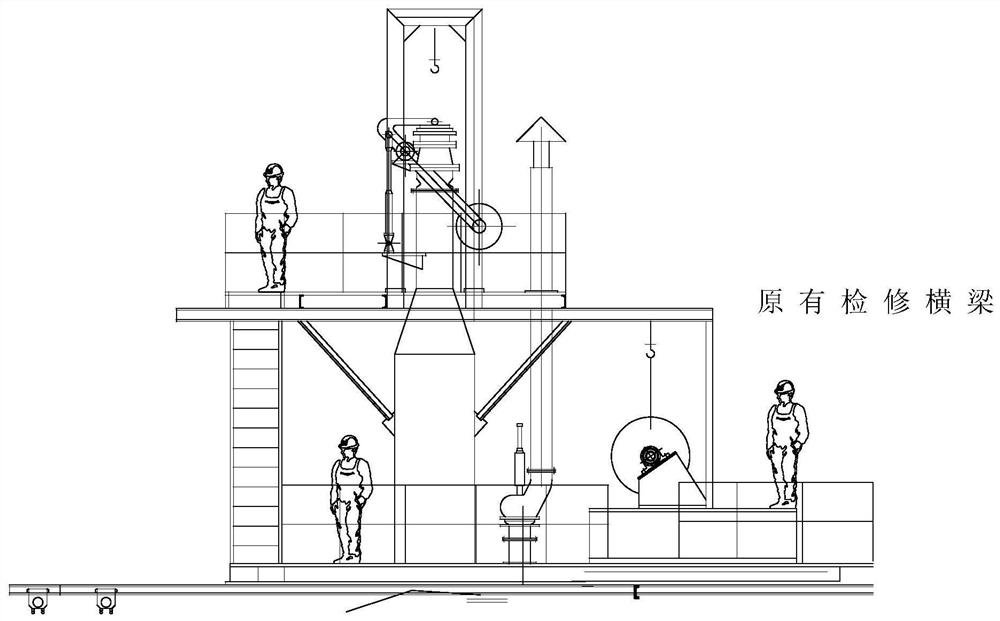

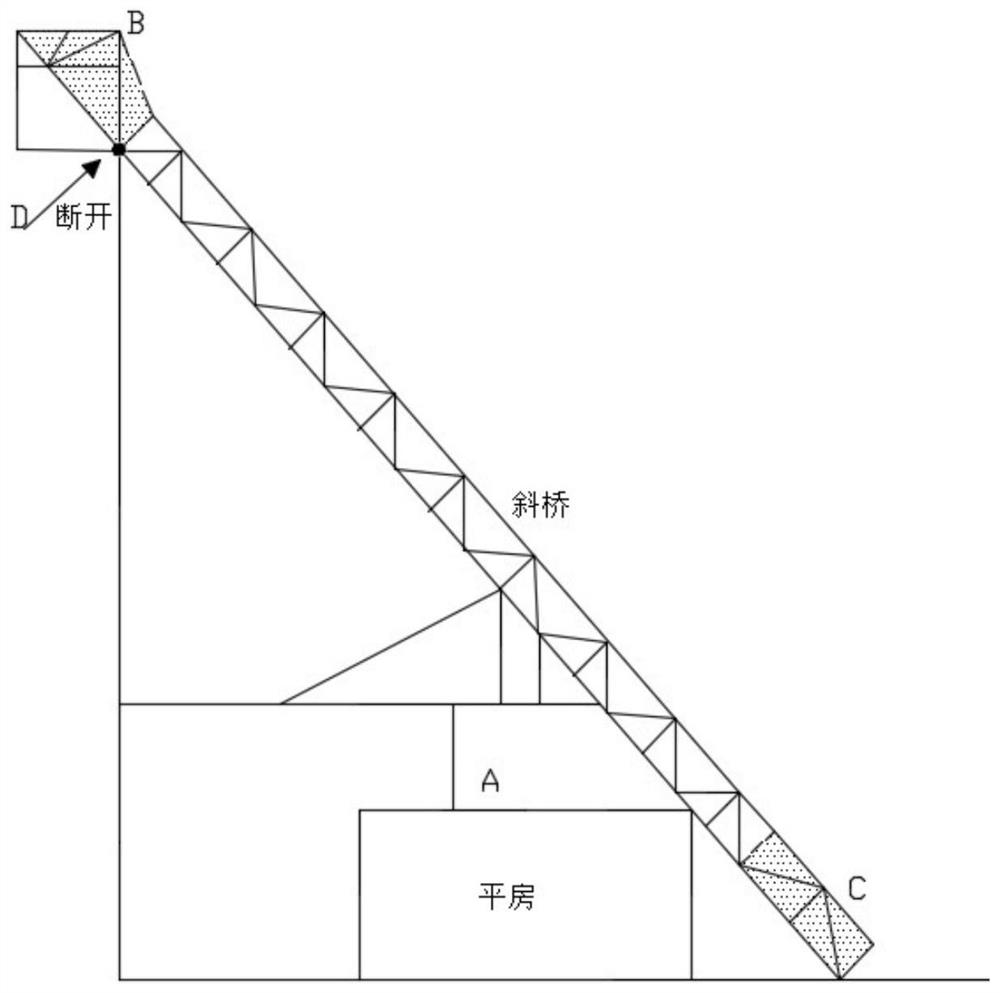

[0025] The structure of the present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

[0026] Since the top of the inclined bridge is an independent structure, it is not connected to the steel frame platform of the blast furnace roof, and the top H steel is independently supported. Therefore, the top pretreatment of the inclined bridge cannot be simply disconnected, but is divided into sections from top to bottom. It is fixed first and then cut, so that it slowly falls onto the platform under the control of the traction rope, and all the top is cut and processed, and then emptied, and only the two main trusses at the lower part of the inclined bridge are not cut for the time being. After the top and roots are all pretreated, the top truss is cut diagonally to the main steel beam so that it naturally slides down to the ground.

[0027] like Figure 1 to Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com