A large-diameter cement pipe section handling device for road construction

A technology for road construction and handling devices, applied in the direction of hoisting devices, etc., can solve the problems of inability to carry and move by pipelines, and achieve the effect of improving flexibility and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

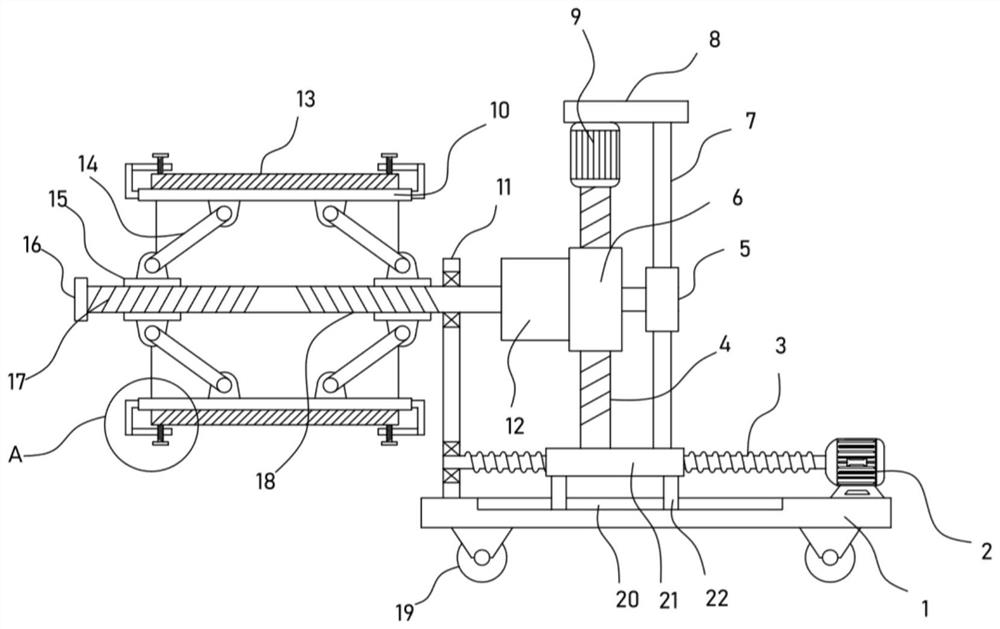

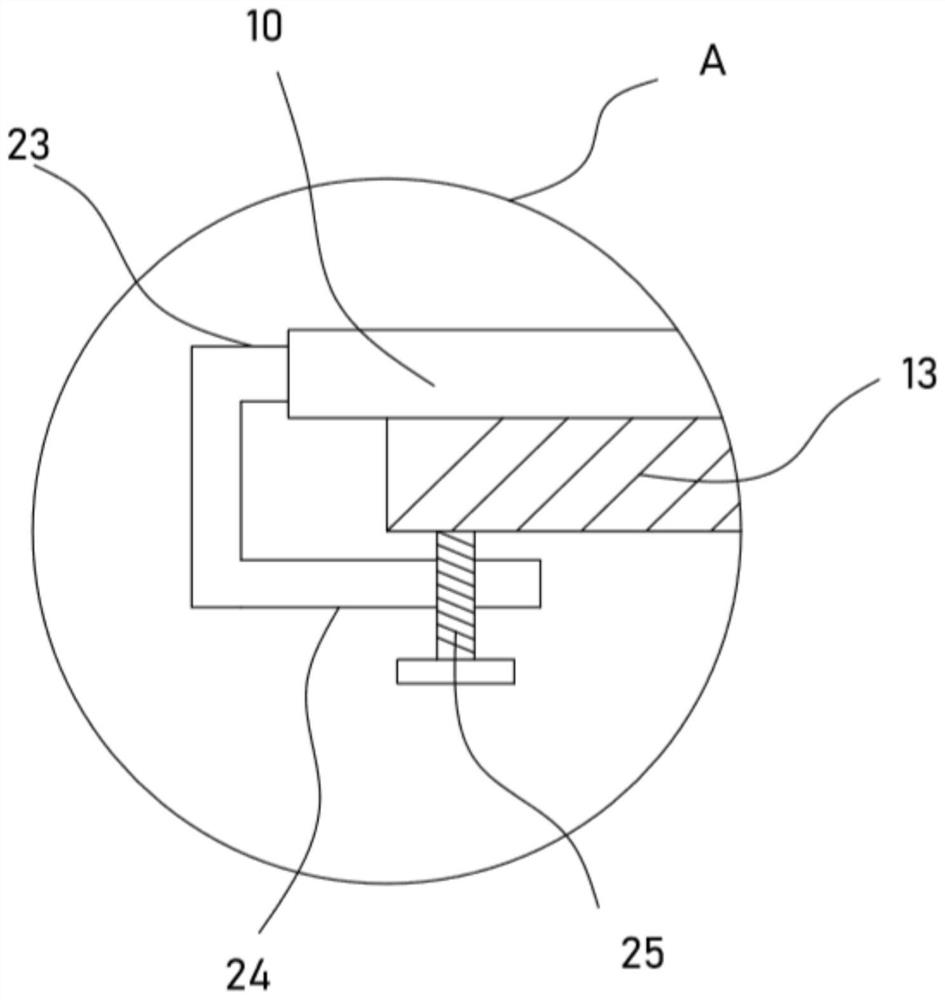

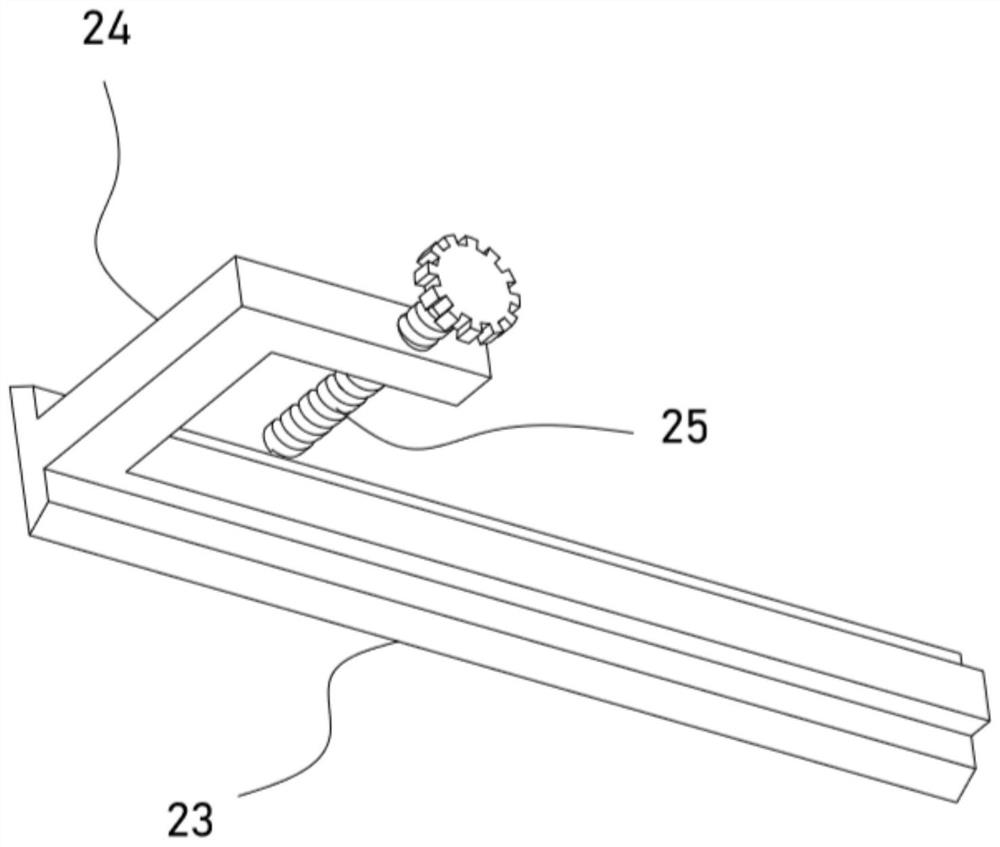

[0022] see Figure 1-4 , a large-diameter cement pipe section handling device for road construction, comprising a mobile plate 1, the bottom of the mobile plate 1 is rotatably mounted with a walking wheel 19, the mobile plate 1 is vertically fixed on the mobile plate 1, and the mobile plate 1 is provided with a horizontal adjustment mechanism. Sliding threaded block 21, the threaded block 21 is vertically fixed with a guide column 7, and a longitudinal adjustment mechanism is slidably installed on the guide column 7. The longitudinal adjustment mechanism includes a threaded pipe 6, and the threaded pipe 6 is fixed with a servo motor III12, a servo motor III12 The output shaft drive is connected with a clamping mechanism for clamping the cement pipe section 13.

[0023] When carrying out the cement pipe section 13, the traveling wheel 19 drives the mobile plate 1 to move to the position area of the cement pipe section 13, and the cement pipe section 13 is clamped and fixed by...

Embodiment 2

[0029] In order to improve the flexibility of the device for handling the cement pipe section 13 and improve the handling efficiency, on the basis of Embodiment 1, the lateral adjustment mechanism includes a translation threaded rod 3 that is threadedly connected to the penetration block 21, and the translation threaded rod 3 is driven A servo motor I2 fixed on the mobile flat panel 1 is connected.

[0030] The servo motor I2 can drive the translational threaded rod 3 to rotate, and the translational threaded rod 3 drives the threaded block 21 on it to move laterally, thereby realizing the lateral position movement adjustment of the guide column 7 together with the longitudinal adjustment mechanism and the clamping mechanism, and finally realizing the adjustment of the horizontal position of the guide column 7. The movement and handling of the lateral position of the cement pipe section 13.

[0031] In order to ensure the stability of the lateral movement of the cement pipe se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com