Precipitation well construction device

A technology of construction device and dewatering well, which is applied to the drilling driving device, drilling equipment, infrastructure engineering and other directions in the wellbore, can solve the problems of low construction efficiency, poor effect and many processes, save construction period and materials, The construction difficulty is high and the effect of avoiding the collapse of the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] A precipitation well construction device, the working steps are:

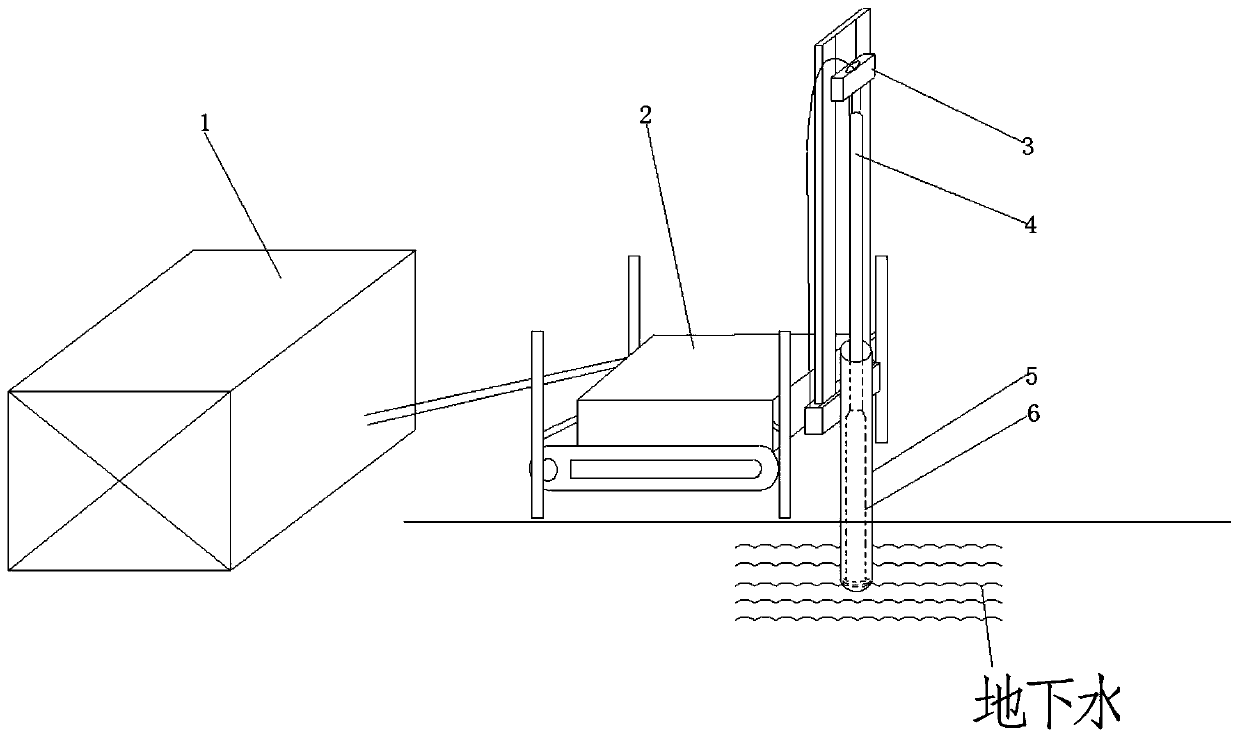

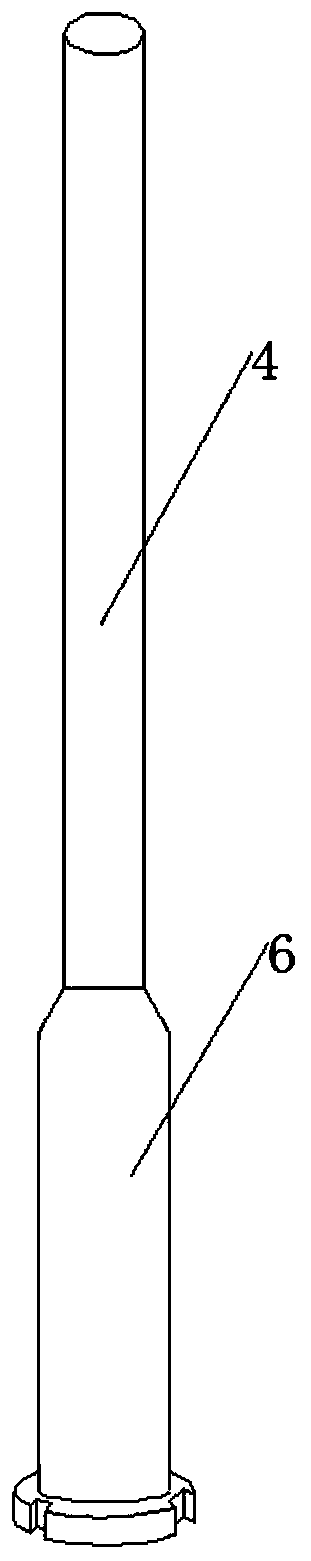

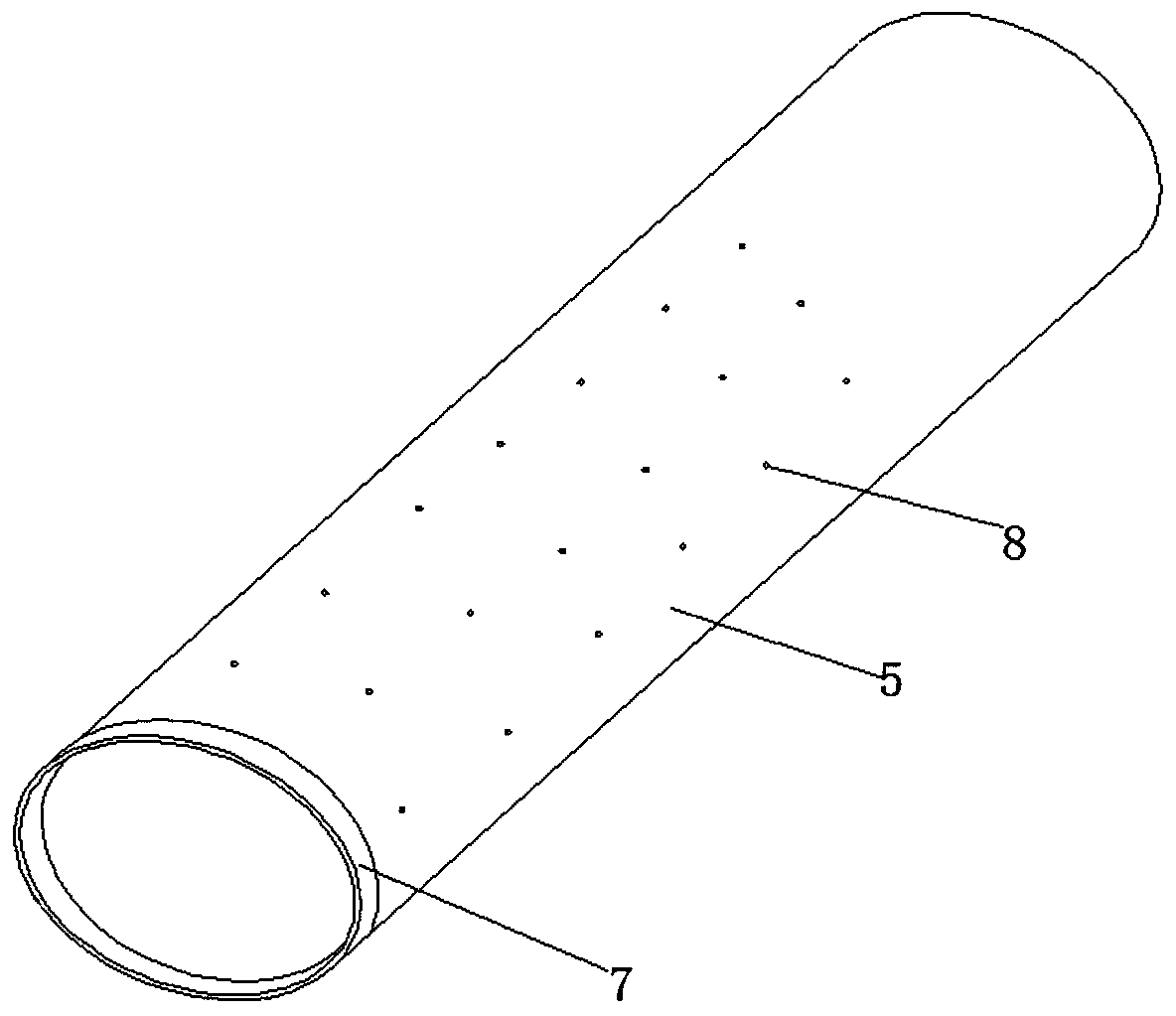

[0020] S1, such as figure 1 As shown, locate the dewatering well, transport the air compressor 1, drilling rig 2, presser 3, connecting rod 4, hammer head 6 and downwater pipe 5 to the dewatering well position, wherein the air compressor 1 supplies energy for the drilling rig 2, and presses The device 3 is installed on the rig 2, such as figure 2 As shown, the hammer head 6 is threadedly connected to the bottom end of the connecting rod 4, such as image 3 As shown, the downcomer 5 is provided with a filter material hole 8 along the line (the distance between the filter material hole 8 is 15-25cm, preferably 20cm, and the effect is to prevent impurities from entering the downcomer 5 while being permeable) and the bottom end is welded and fixed with a reinforcement ring 7 , ham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com