Rapid construction method and structure of secant pile and steel jacket box combined cofferdam

A technology of combining cofferdams and occlusal piles, which is used in infrastructure engineering, sheet pile walls, water conservancy projects, etc., can solve the problem of difficult to meet the requirements of the water resistance rate of river sections, the increase in the amount of excavation of foundation pits for backfill costs, and the problems of steel sheet piles. and the construction difficulties of steel pipe piles, to achieve the effect of reducing temporary structure investment, shortening construction period and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

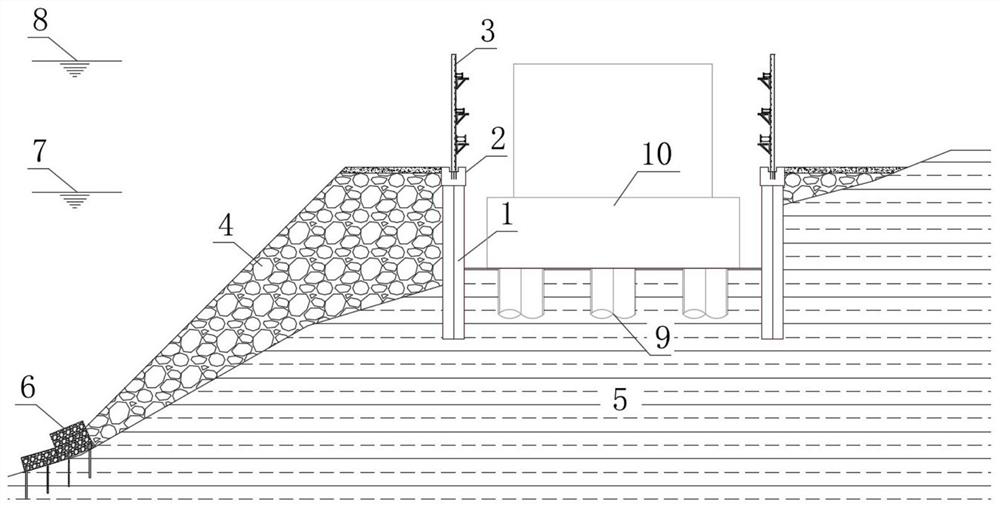

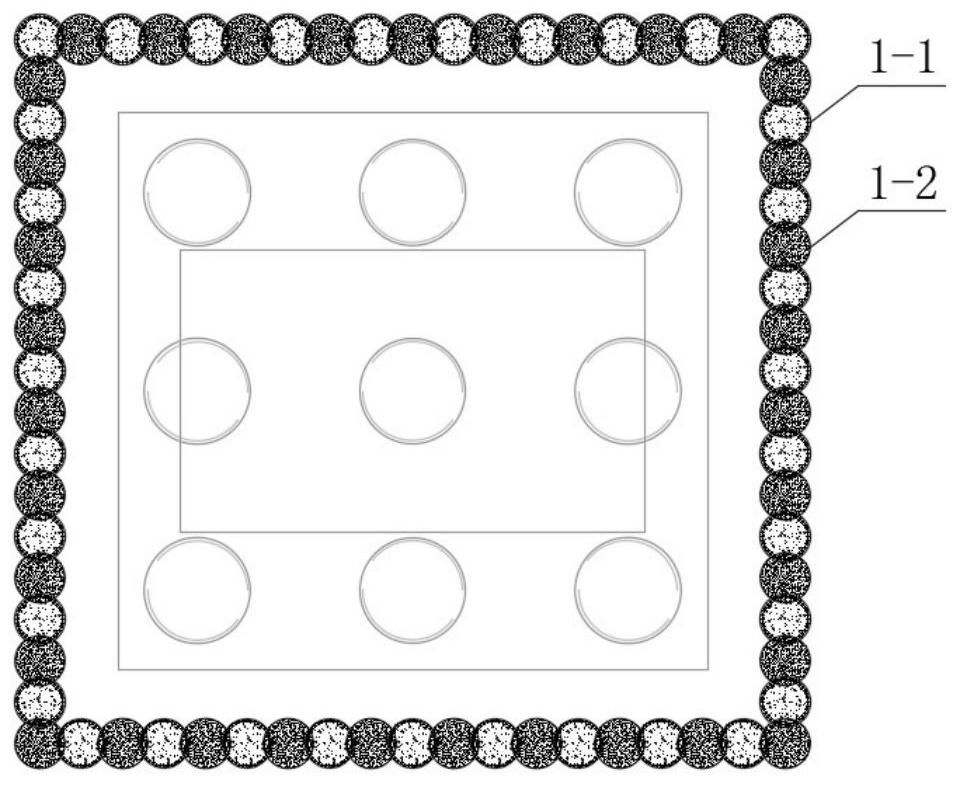

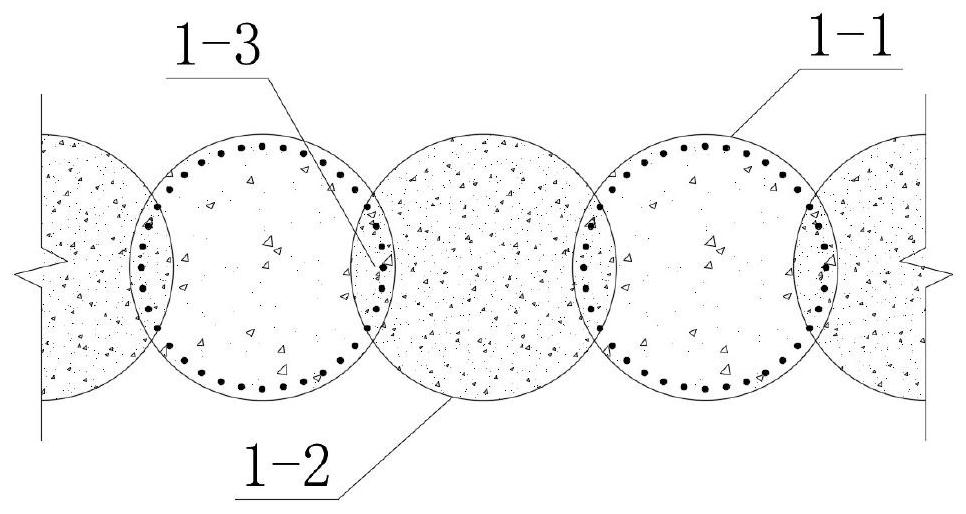

[0047] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be described below in conjunction with the accompanying drawings. It should be noted that throughout the drawings, the same components are indicated by the same or similar symbols. Components in illustrations do not reflect actual size and shape.

[0048] A construction method for the combined cofferdam structure of occlusal piles and steel casings. The method constructs occlusal piles and pile foundations by filling small-scale artificial islands during the constant water level period, and then excavates the foundation pit to install steel casing cofferdams, so as to achieve faster Speed construction completes the combined cofferdam, and the specific implementation steps are as follows:

[0049] S1. Before the construction of the pile foundation, construct the artificial island during the normal water level period, locate the slope foot of the artific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com