Rapid and safe manual oiling device and using method thereof

A refueling device and a safe technology, which is applied in the distribution device, quantitative device, engine lubrication, etc., can solve the problems of time-consuming and laborious disassembly, low efficiency, dust influence, etc., to simplify the refueling operation steps and reduce downtime , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

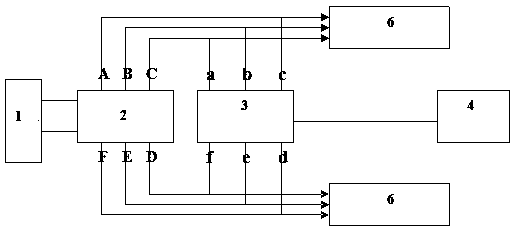

[0020] Such as figure 1 As shown, A-F is the oil outlet of the first-stage dry oil distributor; a-f is the oil outlet of the progressive dry oil distributor; the other end of the tee is the dry oil pipeline connected to the lubricating part of the equipment. A progressive dry oil distributor is installed in the safe part of the equipment. The six oil outlets a-f of the progressive dry oil distributor are respectively connected to the dry oil pipeline connected to the lubrication point of the equipment in parallel with a three-way connection. When manually refueling, you only need to connect the oil inlet of the progressive dry oil distributor to the oil outlet pipeline of the manual lubrication pump. After starting the manual lubrication pump, all the lubrication points of the equipment can be lubricated. The whole operation process only The pipeline needs to be disassembled once, and the oil outlets A-F of the first-stage dry oil distributor do not need to be disassembled, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com