Online monitoring system for hump signal device and online monitoring method for switch machine

A technology of signal equipment and monitoring system, applied in the field of on-line monitoring system of hump signal equipment, which can solve problems such as on-site fault location, troublesome troubleshooting, lack of electrical parameter record data, hidden danger of signal equipment failure can not be discovered in time, etc., so as to facilitate failure Analysis, the effect of convenient data recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

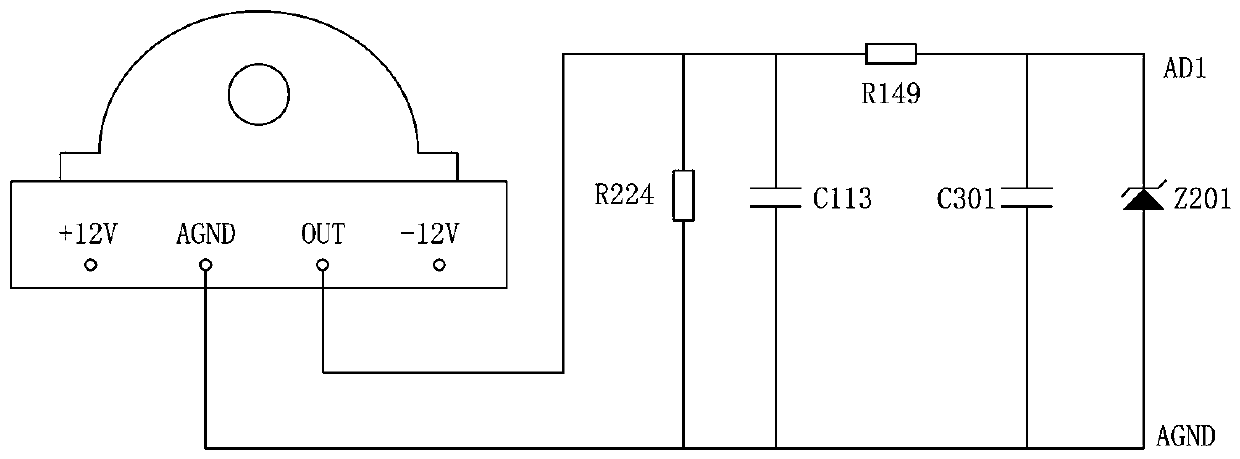

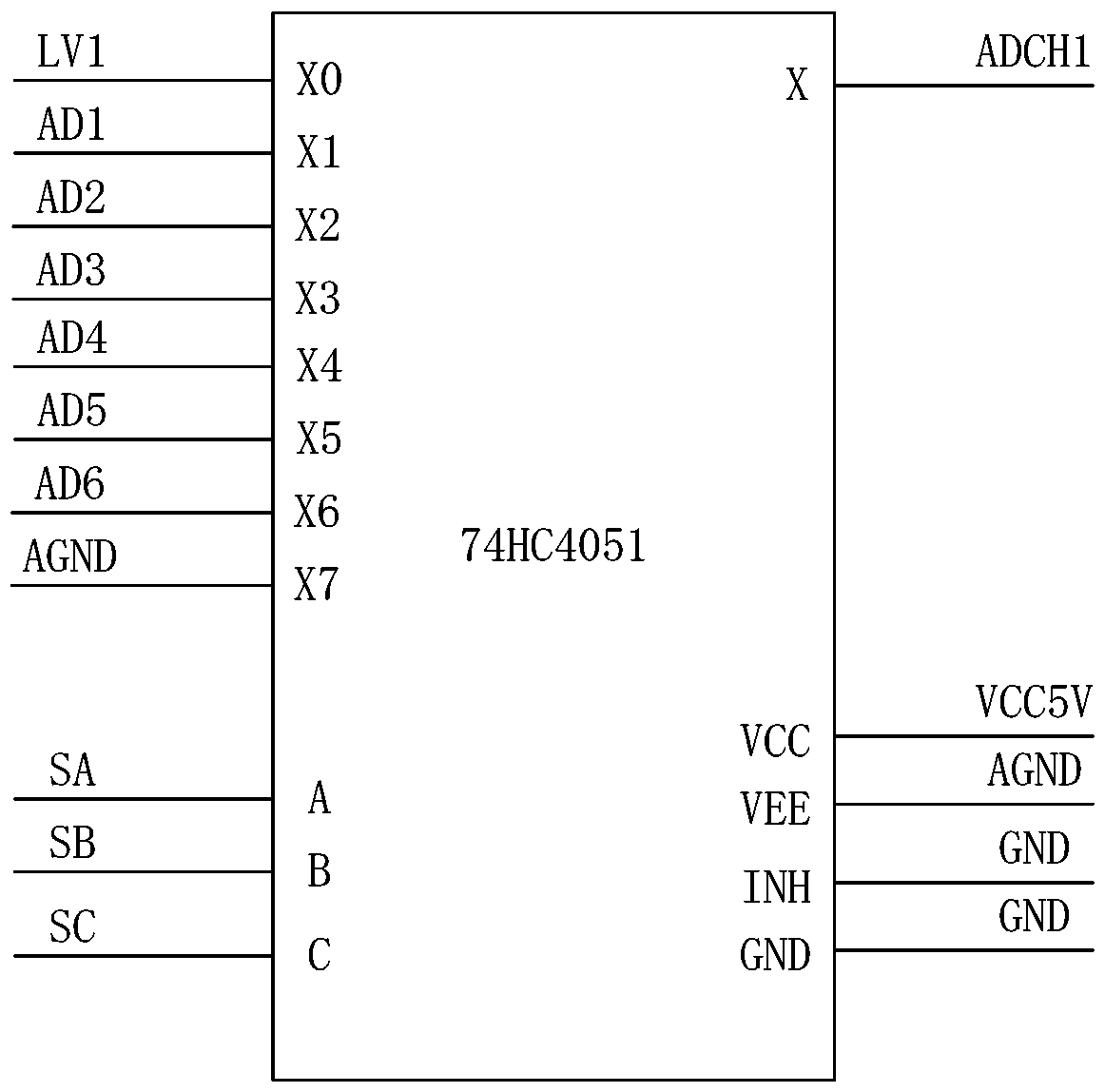

[0042] Such as figure 2 As shown, in view of the fast action of the ZK4 electro-pneumatic switch machine and the characteristics of the current value of the solenoid valve as a small signal DC, the current detection circuit at the sending end of the solenoid valve in this embodiment includes a perforated Hall current transformer, and according to the safety design principle, a perforated Hall current transformers are used to collect raw data, and the sampling locations are as follows Figure 8 As shown in the figure, pass the sending end line (i.e. the input side line) of the solenoid valve on the electropneumatic switch machine through the middle of the perforated Hall current transformer. The perforated Hall current transformer needs ±12V power supply, and the output of the perforated Hall current transformer After filtering and voltage stabilization, the analog multiplexer 74HC4051 is output to the AD port of the DSP, and the acquisition is completed by the DSP. The pin co...

Embodiment 2

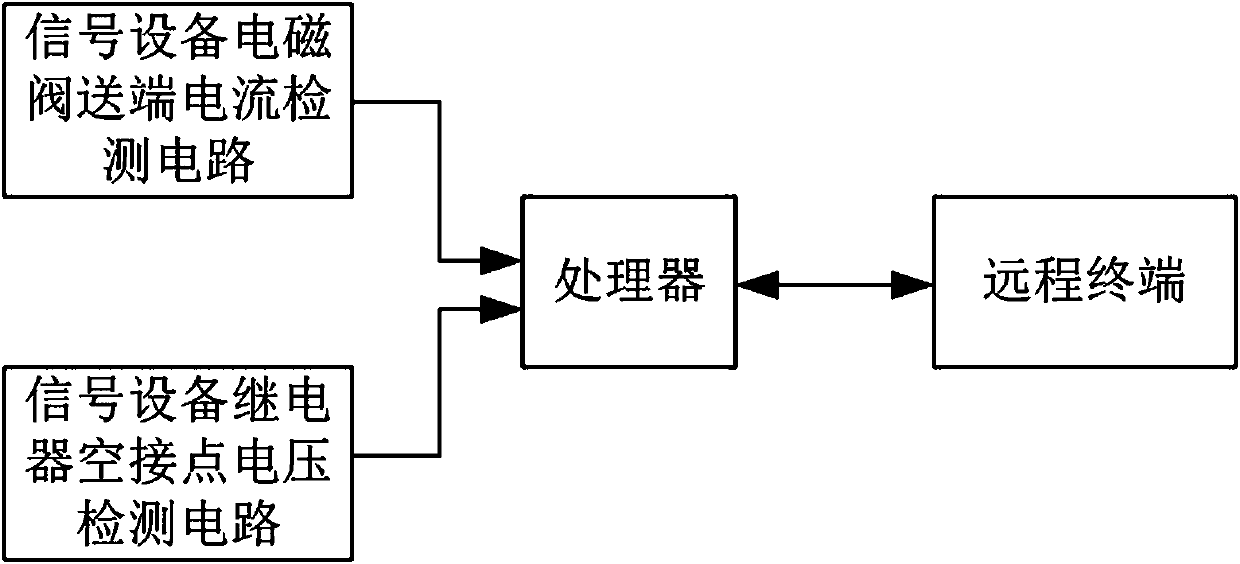

[0056] Such as Figure 9 As shown, the online monitoring system in this embodiment includes the voltage detection circuit at the sending end of the reducer, the current detection circuit of the solenoid valve at the sending end, and the relay state detection circuit. The detection circuits are all connected to the processing unit (that is, the electrical parameter acquisition system of the reducer), and the electrical parameter acquisition system of the reducer is connected to the remote terminal through the hump signal centralized monitoring system and the server in turn.

[0057] The current detection circuit at the sending end of the solenoid valve in this embodiment is the same as that in Embodiment 1, as figure 2 As shown, the perforated Hall current transformer is included, and according to the safety design principle, the perforated Hall current transformer is used for raw data collection, and the sending end line (ie, the input side line) of the solenoid valve on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com