A magnetic levitation projectile shuttle precision weft insertion control method and system, and information processing terminal

A control method, magnetic levitation technology, applied in general control systems, control/regulation systems, textiles and papermaking, etc., can solve problems such as low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

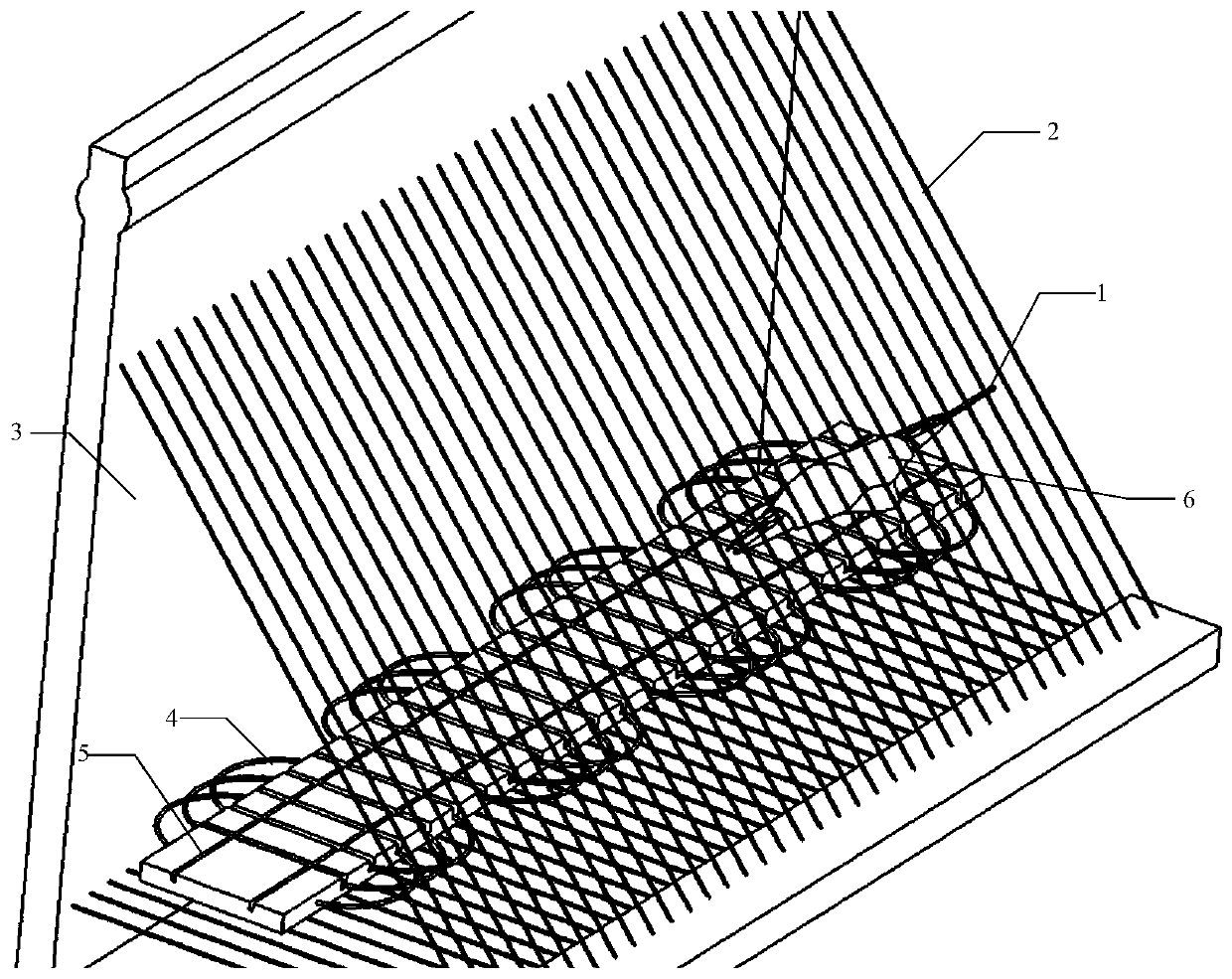

[0136] In the dynamic weft insertion mathematical model of the maglev projectile shuttle provided by the present invention, the maglev system uses a magnetic field as a medium to realize energy transfer and transformation. In most cases, magnetic fields are generated by electrical energy. With the change of the gap between the maglev projectile and the weft insertion track in the magnetic field, the strength of the magnetic field generated by the electromagnet also changes accordingly, and the levitation system thus established is an unstable equilibrium point. Through proper feedback, the excitation current changes, resulting in a corresponding change in the magnetic field strength, transforming the unstable equilibrium point into a stable equilibrium point, and ensuring the real frictionless high-speed weft insertion of the suspension gripper.

[0137] The electromagnetic levitation system uses the magnetic field as a medium to realize the transfer and conversion of energy. ...

Embodiment 2

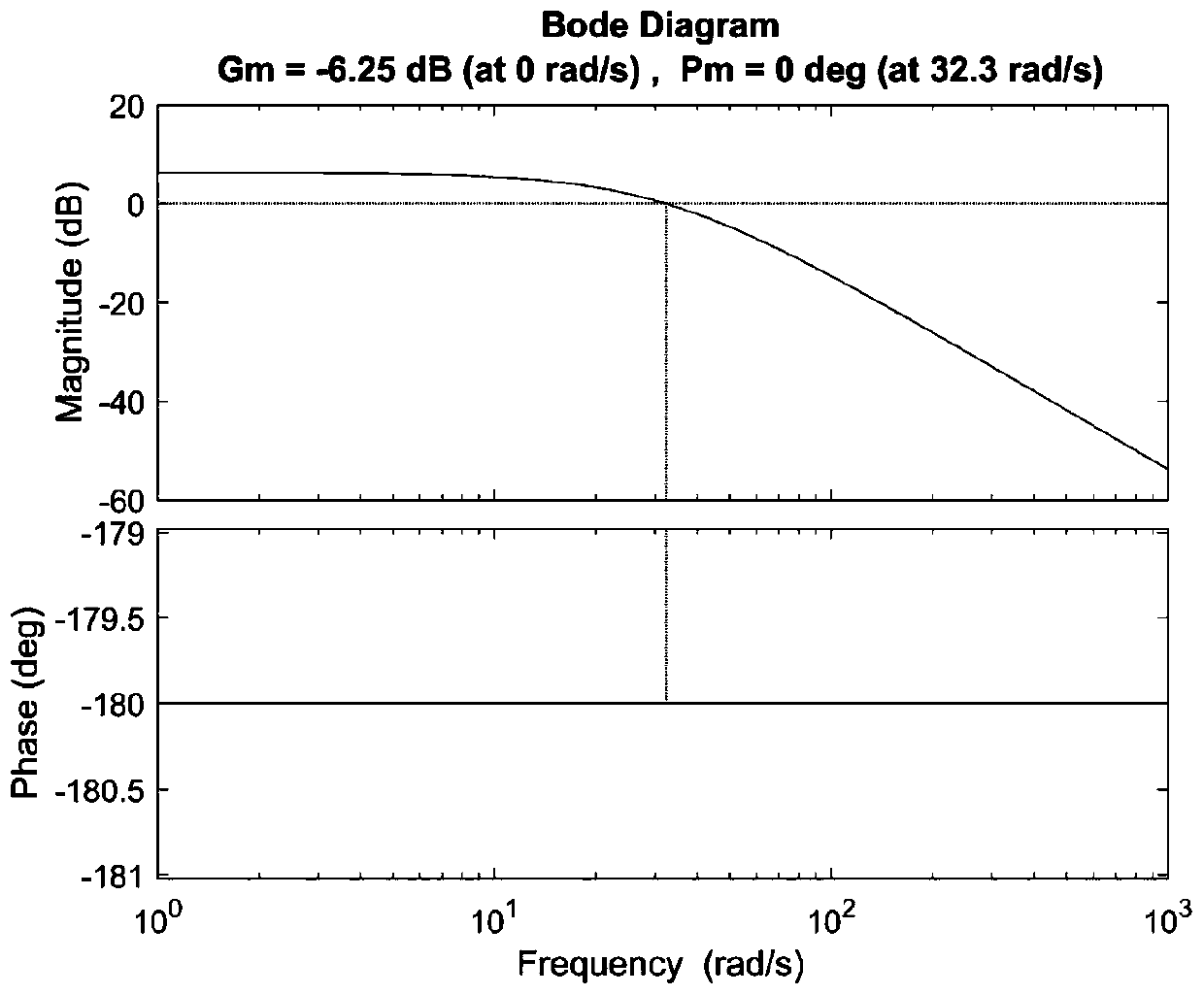

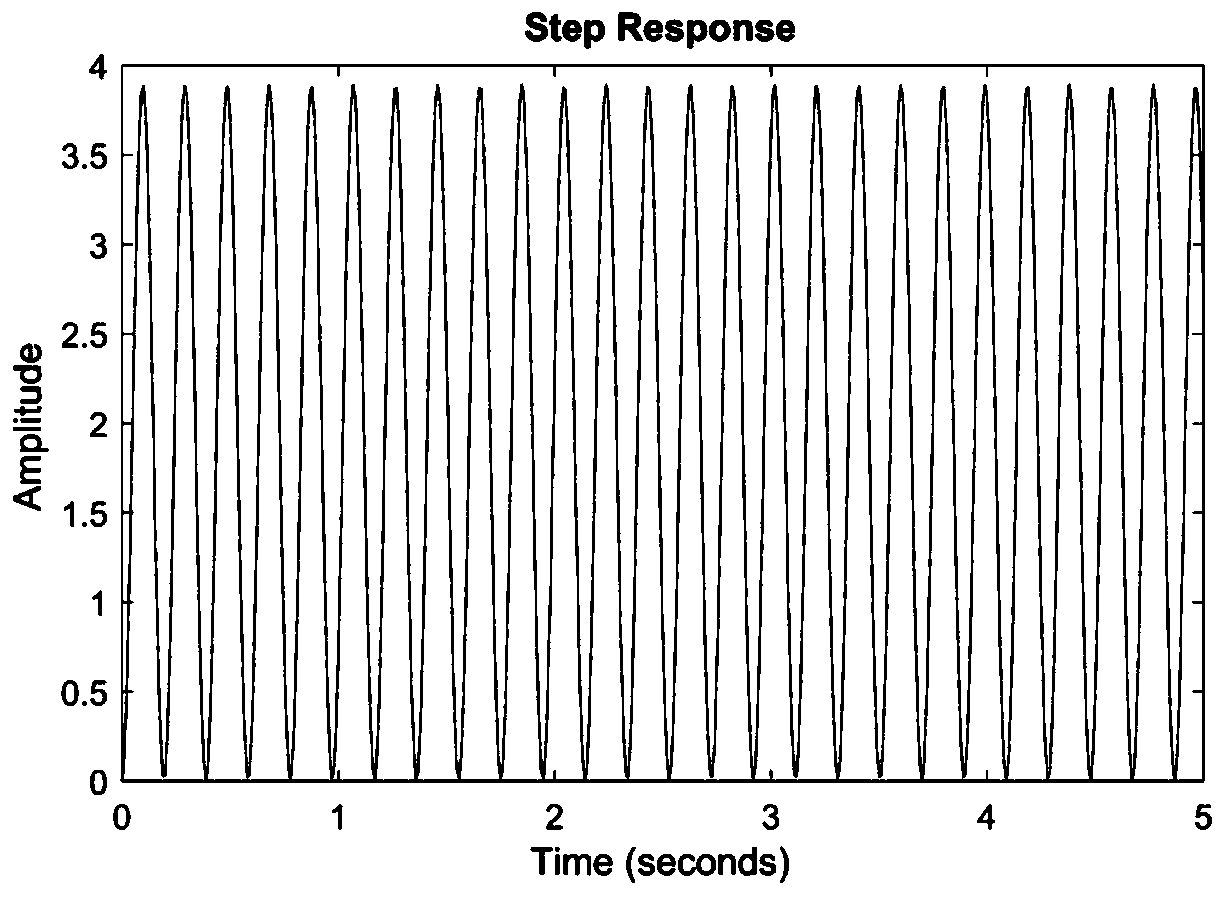

[0188] Adding a correction network to the system changes the entire system, optimizes the given performance indicators, and adds a suitable correction device to make the system's performance fully meet the design requirements.

[0189] System calibration is to add mechanisms or devices to the system to change the frequency characteristics of the system to meet the above-mentioned given performance indicators. The correction device is generally equipped in the forward channel of the system, and the access location depends on the physical characteristics of the correction device itself and the structure of the original system. In general, small and light-weight correction devices are often added to places where the system signal capacity is small and the power is low, that is, in the forward channel closer to the input signal.

[0190] In the design of the control system, the design methods adopted are generally determined according to the form of performance indicators, mainly ...

Embodiment 3

[0193] An embodiment of the present invention provides a lag-lead correction parameter setting method with series correction, which includes the following steps:

[0194] (a) Identify the open-loop frequency response of the controlled object.

[0195] (b) Determine the expected phase margin, amplitude margin and open-loop frequency response of the controlled object according to the actual requirements of the system overshoot, response time, peak value, etc., and change the parameters of the lag-lead-lag corrector to A unary function with the system open-loop cutoff frequency as an argument

[0196] (c) Calculate the lag-lead control parameters. In the present invention, the structural parameter of lag lead correction is:

[0197]

[0198] The frequency parameters of the correction system are selected based on the initial system bode diagram.

[0199] (d) According to design indicators such as steady-state accuracy (error coefficient), phase margin (overshoot) and adjustm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap