Method for optimizing smoothness of whole vehicle by utilizing liquid resistance suspension

A technology of liquid resistance mounting and optimization method, which is applied to power plants, vehicle components, jet propulsion devices, etc., can solve the problems such as the inability to consider vibration, the inability to consider the powertrain mounting system and chassis vibration at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

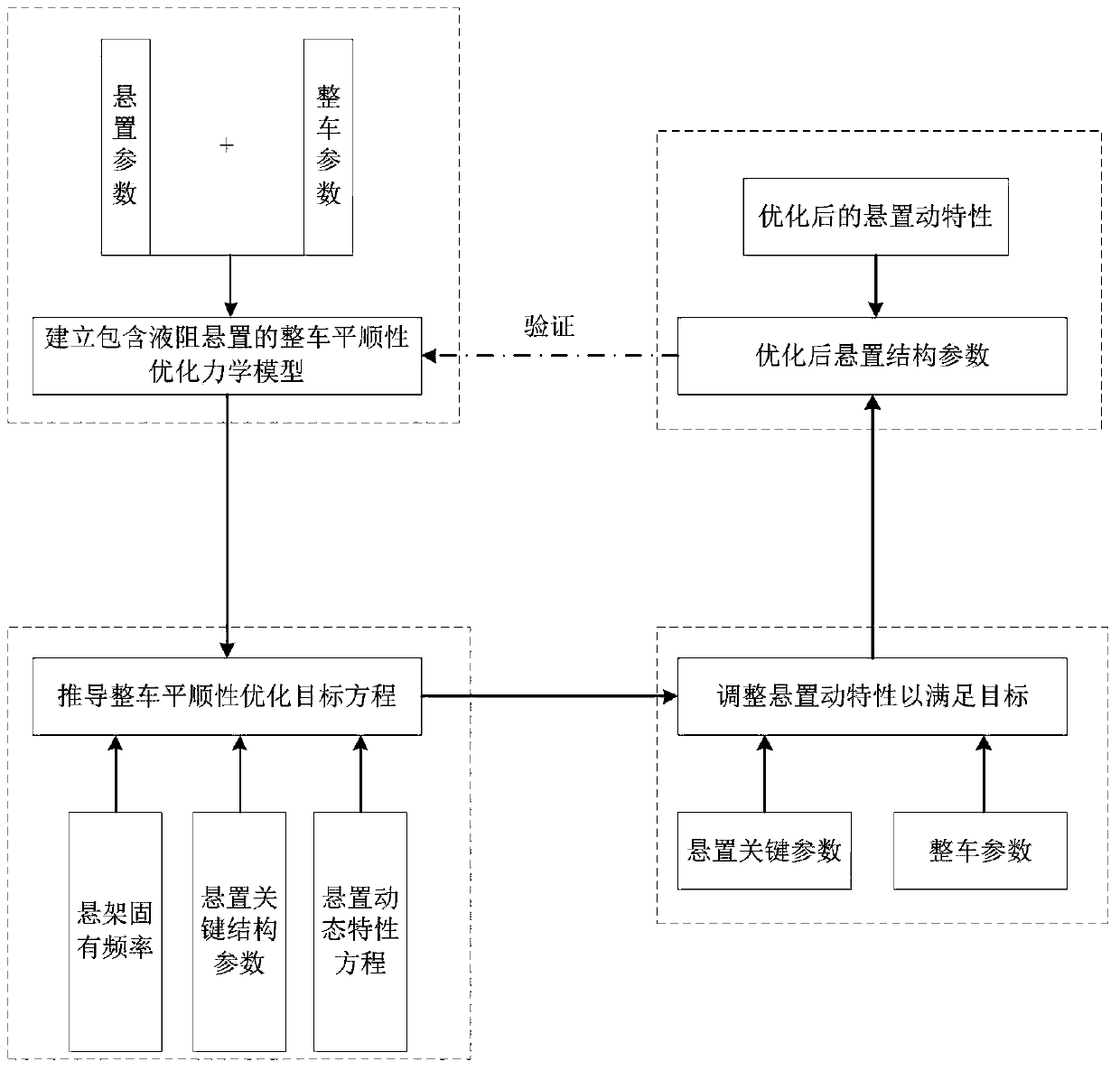

[0073] The present invention is realized by adopting the following technical solutions, which are described as follows in conjunction with the accompanying drawings:

[0074] The invention proposes that the ride comfort optimization method and the system principle of the whole vehicle using liquid resistance mounts can be realized by using any programming language, and the results can be verified by road test or multi-body dynamics software simulation.

[0075] A method for optimizing ride comfort of a vehicle using a hydraulic mount, comprising the following steps:

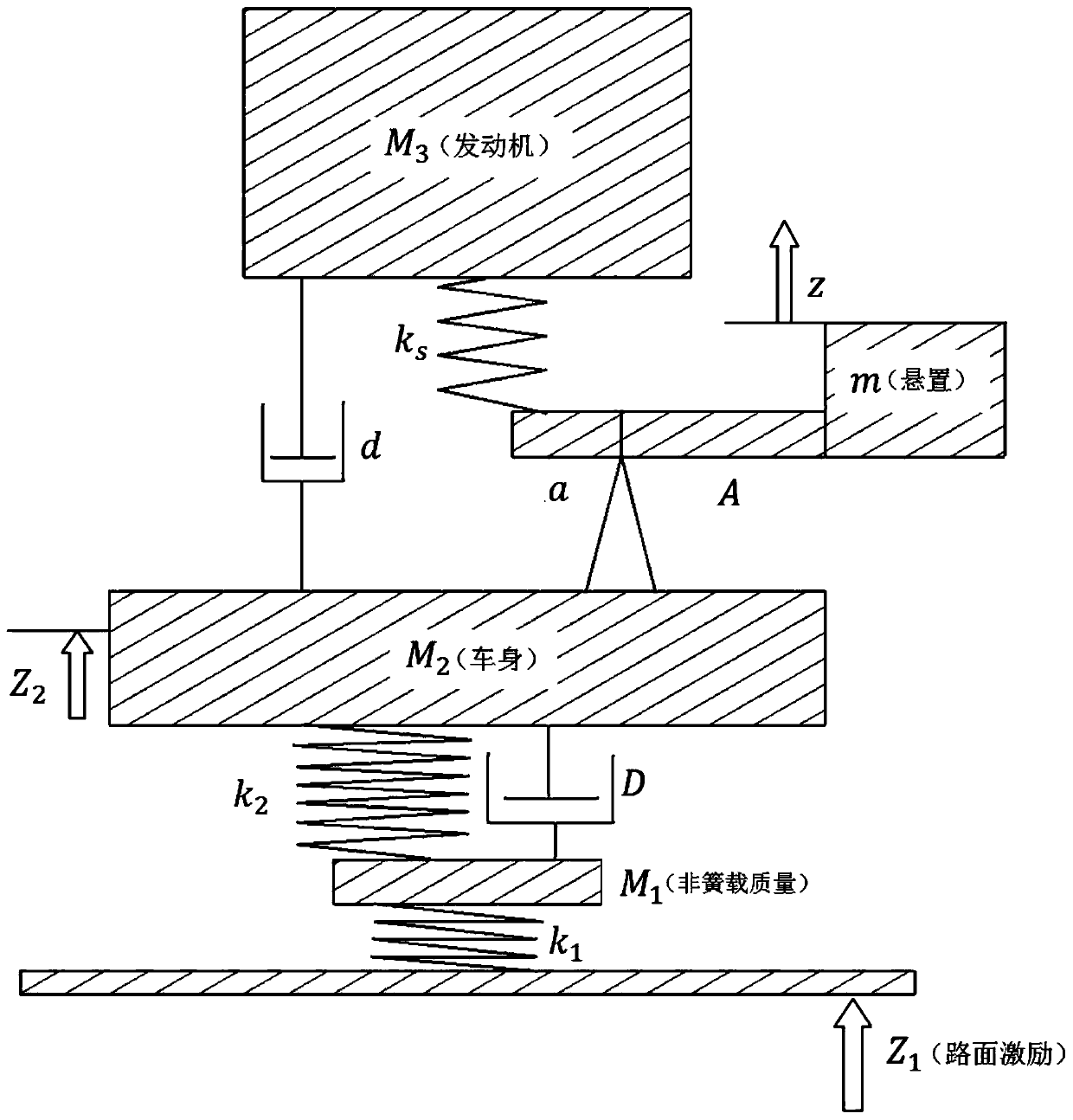

[0076] a. Establish a 1 / 4 mechanical model of the whole vehicle for analysis: the model includes the powertrain mass M 3 , the mass of inertial damping liquid column of liquid resistance mount m, the cross-sectional area of flow channel of liquid resistance mount a, the equivalent piston area of liquid resistance mount A, and the mass of vehicle body M 2 , the unsprung mass of the suspension M 1 , rubber st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com