Preparation method of imprinting material for detecting dioctyl phthalate

A technology for dioctyl phthalate and imprinted materials, which is applied in the field of preparation of imprinted materials for detection of dioctyl phthalate, can solve the problems of poor selectivity of molecular imprinted materials, and achieve good environmental compatibility and high stability properties, increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

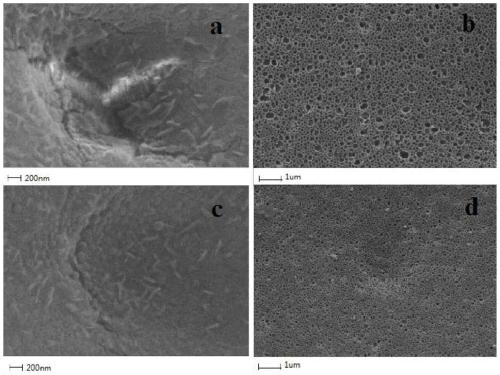

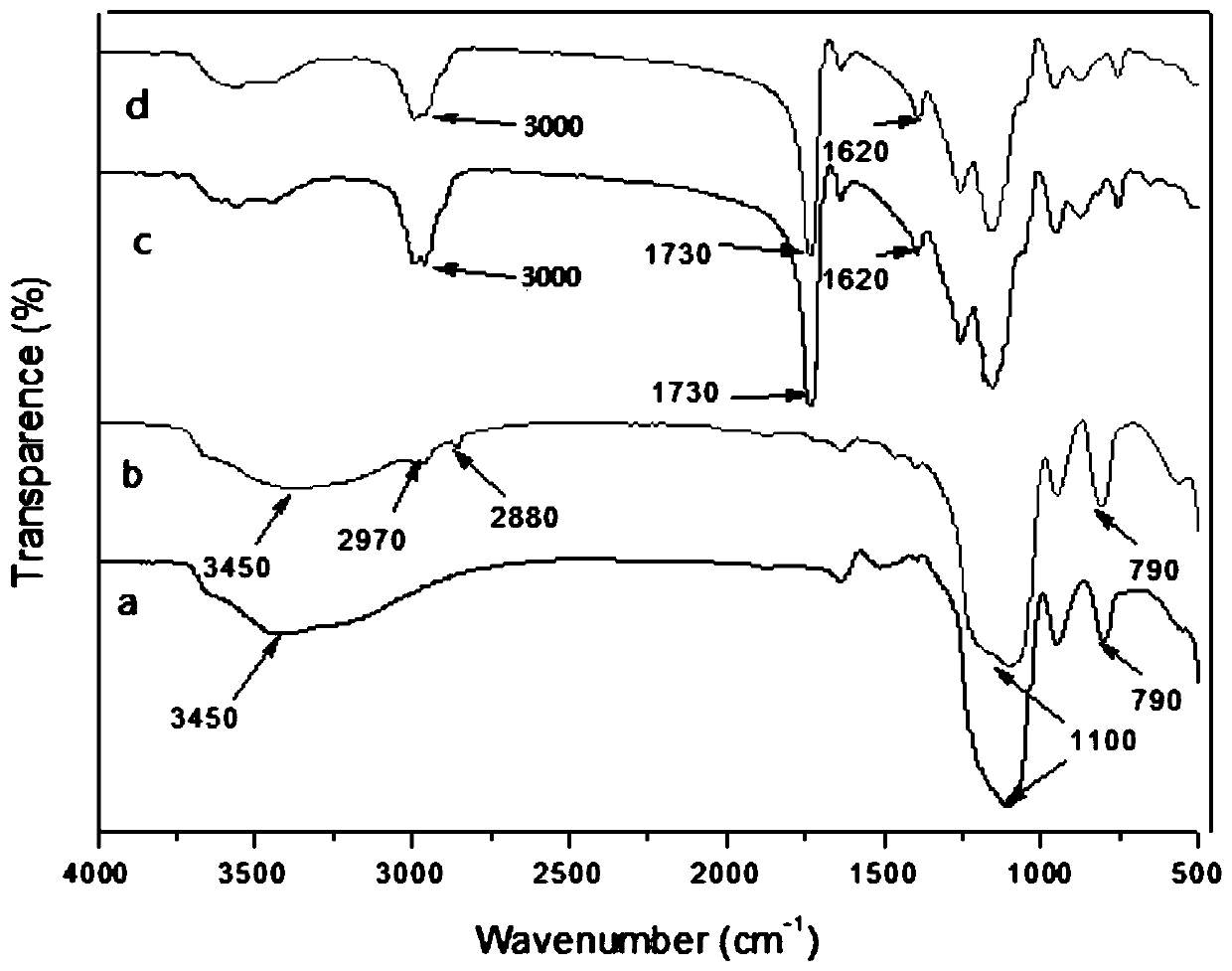

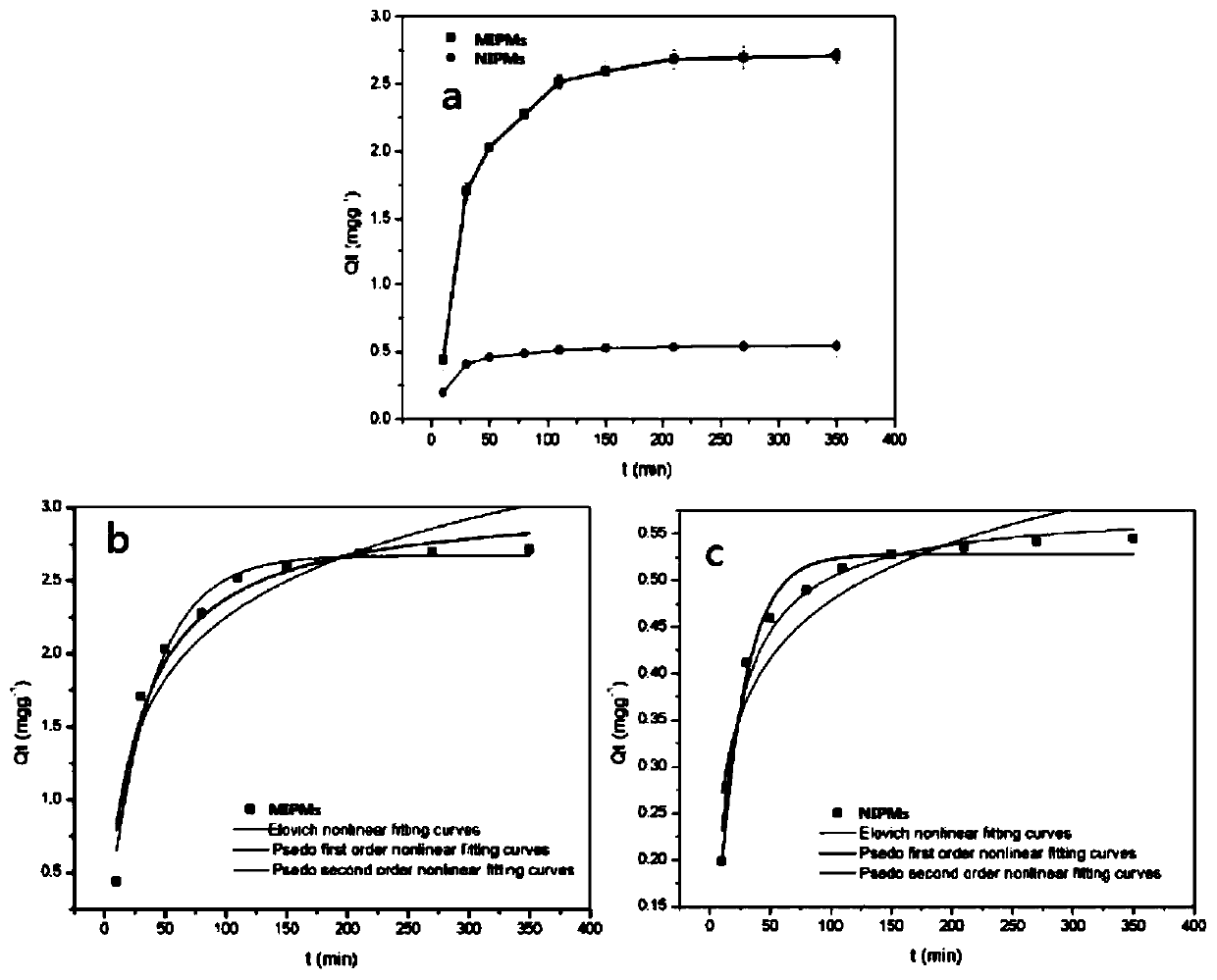

Image

Examples

Embodiment 1

[0031] Step 1, preparation of silica nanoparticles: first, mix 12.5mL of absolute ethanol / methanol / isopropanol and 1.05mL of ultrapure water in a three-necked flask; then, add 0.305mL of ammonia water to the solution, Adjust the pH to 10; slowly add 2.1mL tetraethyl orthosilicate and 2.5mL ethanol mixture into the above solution slowly; then, heat in a water bath at 25°C and mechanically stir for 24h; finally, centrifuge the obtained colloidal solution (9000 rev / min), ultrasonically cleaned 5 times with ethanol, vacuum dried at 40°C for 12h, recorded as: SiO 2 .

[0032] Step 2. SiO modified by γ-(methacryloyloxy)propyltrimethoxysilane2 : First 2.5g SiO 2 and 50mL of methanol into a 125mL three-necked flask, ultrasonicated for 15min; then 0.2mL of ammonia water was added to the SiO 2 In the suspension, under heating in a water bath at 45°C, stir mechanically, and slowly add 0.125g of γ-(methacryloyloxy)propyltrimethoxysilane dropwise to the above solution during this process...

Embodiment 2

[0036] Step 1. Preparation of silica nanoparticles: First, mix 25 mL of absolute ethanol / methanol / isopropanol and 2.1 mL of ultrapure water in a three-necked flask; then, add 0.61 mL of ammonia to the solution, Adjust the pH to 10; then slowly add 4.2mL tetraethyl orthosilicate and 5mL ethanol mixture dropwise into the above solution; then, heat in a water bath at 25°C and mechanically stir for 24h; finally, centrifuge the obtained colloidal solution ( 9000 rev / min), ultrasonic cleaning with ethanol 5 times, vacuum drying at 40°C for 12h, denoted as: SiO 2 .

[0037] Step 2. SiO modified by γ-(methacryloyloxy)propyltrimethoxysilane 2 : First 5g SiO 2 and 100mL of methanol into a 250mL three-neck flask, ultrasonicated for 15min; then 0.3mL of ammonia water was added to the SiO 2 In the suspension, under heating in a water bath at 45°C, stir mechanically, and slowly add 0.25g of γ-(methacryloyloxy)propyltrimethoxysilane to the above solution dropwise during this process; afte...

Embodiment 3

[0041] Step 1. Preparation of silica nanoparticles: First, mix 37.5 mL of absolute ethanol / methanol / isopropanol and 3.15 mL of ultrapure water in a three-necked flask; then, add 0.915 mL of ammonia to the solution , adjust the pH to 10; then slowly drop the mixture of 6.3mL tetraethyl orthosilicate and 7.5mL ethanol into the above solution; then, heat in a water bath at 25°C and mechanically stir for 24h; finally, the obtained colloidal solution Centrifuge (9000 rev / min), ultrasonically clean with ethanol 5 times, vacuum dry at 40°C for 12h, record as: SiO 2 .

[0042] Step 2. SiO modified by γ-(methacryloyloxy)propyltrimethoxysilane 2 : first 7.5g SiO 2 and 150mL of methanol into a 250mL three-necked flask, ultrasonicated for 15min; then 0.4mL of ammonia water was added to the SiO 2 In the suspension, under heating in a water bath at 45°C, stir mechanically, and slowly add 0.375g of γ-(methacryloyloxy)propyltrimethoxysilane to the above solution dropwise during this proces...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap