An environment-friendly composite material capable of sorting and recycling metals and plastics and its preparation method

A technology for composite materials and composite packaging materials, applied in the field of environment-friendly composite materials and their preparation, to achieve the effects of simple preparation methods, increased gas barrier performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

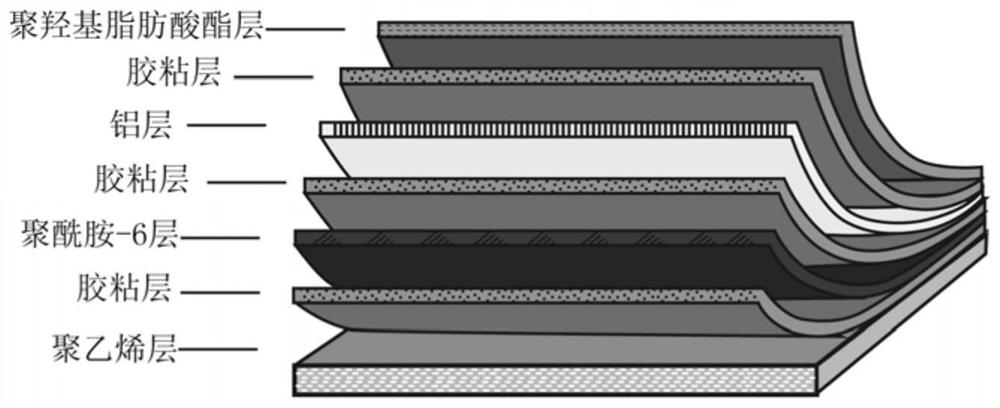

[0053] An environment-friendly composite material, which successively comprises a polyhydroxyalkanoate layer, an adhesive layer, an aluminum layer, an adhesive layer, a polyamide-6 layer, an adhesive layer, and a polyethylene layer; the polyhydroxyalkanoate layer The thickness of the adhesive layer is 12 μm, the thickness of the adhesive layer is 15 μm, the thickness of the aluminum layer is 7 μm, the thickness of the polyamide-6 layer is 15 μm, and the thickness of the polyethylene layer is 60 μm;

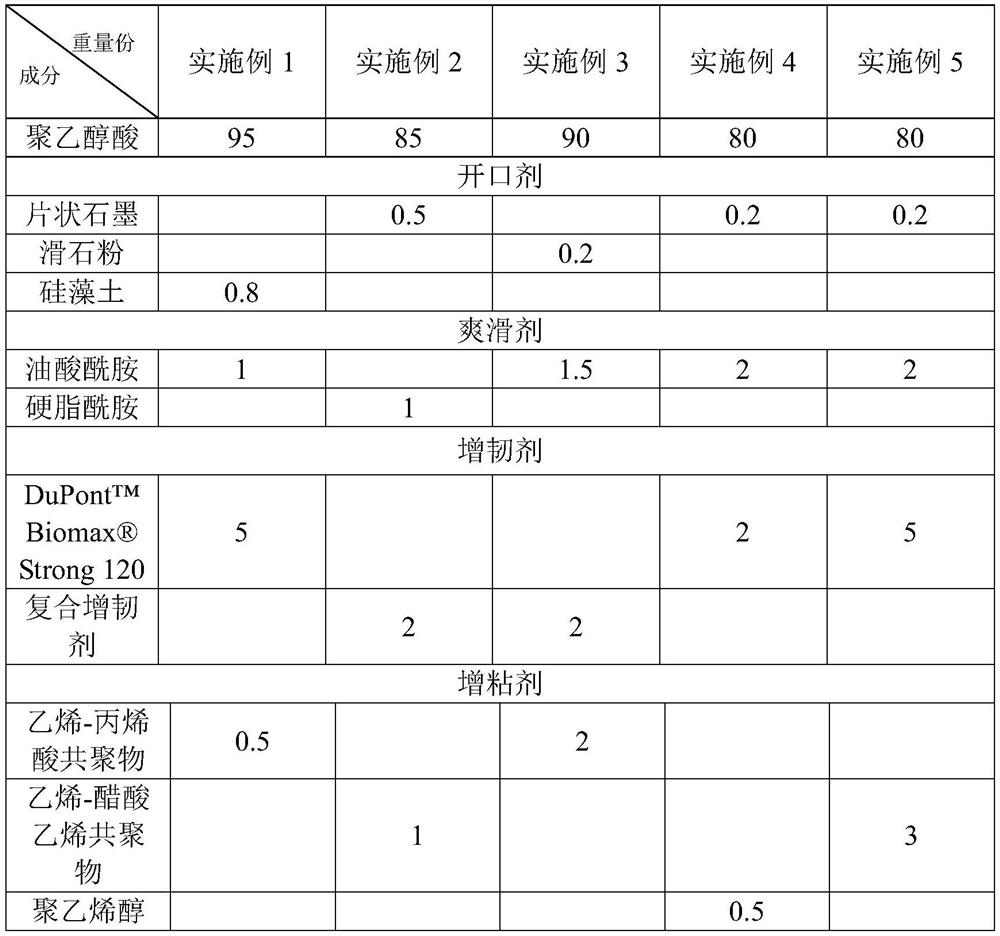

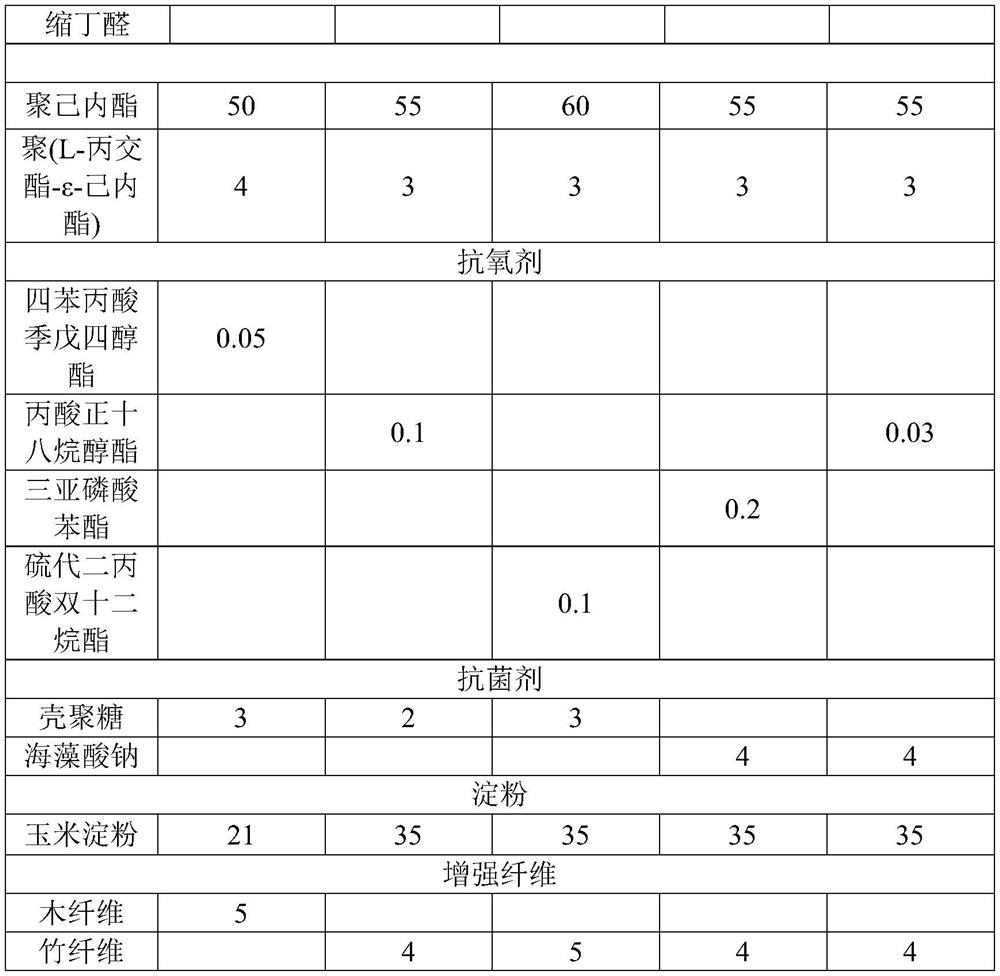

[0054] The adhesive layer is formed of modified polyglycolic acid, and the composition of the modified polyglycolic acid is shown in Table 1.

[0055] The preparation method of the above-mentioned environment-friendly composite material includes:

[0056] S1: Input the modified polyglycolic acid pellets into the first sub-screw extruder in the triple co-extrusion composite production line, make the pellets form a uniform fluid at a melting temperature of 250-350°C, and then extrud...

Embodiment 2

[0065] An environment-friendly composite material, which successively comprises a polyethylene terephthalate layer, an adhesive layer, an aluminum layer, an adhesive layer, a polyamide-66 layer, an adhesive layer, and a polyethylene layer; the polyethylene terephthalate The thickness of the ethylene diformate layer is 12 μm, the thickness of the adhesive layer is 15 μm, the thickness of the aluminum layer is 9 μm, the thickness of the polyamide-66 layer is 15 μm, and the thickness of the polyethylene layer is 90 μm ;

[0066] The adhesive layer is formed of modified polyglycolic acid, and the composition of the modified polyglycolic acid is shown in Table 1.

[0067] The preparation method of the above-mentioned environment-friendly composite material includes:

[0068] S1: Input the modified polyglycolic acid pellets into the first sub-screw extruder in the triple co-extrusion composite production line, make the pellets form a uniform fluid at a melting temperature of 250-35...

Embodiment 3

[0077] An environment-friendly composite material, which successively comprises a polyamide-610 layer, an adhesive layer, an aluminum layer, an adhesive layer, a polyamide-12 layer, an adhesive layer, and a polyethylene layer; the polyamide-610 layer, poly The thickness of the amide-12 layer is 15 μm, the thickness of the adhesive layer is 15 μm, the thickness of the aluminum layer is 9 μm, and the thickness of the polyethylene layer is 90 μm;

[0078] The adhesive layer is formed of modified polyglycolic acid, and the composition of the modified polyglycolic acid is shown in Table 1.

[0079] The preparation method of the above-mentioned environment-friendly composite material includes:

[0080]S1: Input the modified polyglycolic acid pellets into the first sub-screw extruder in the triple co-extrusion composite production line, make the pellets form a uniform fluid at a melting temperature of 250-350°C, and then extrude them through a flat die Pressed to form a cast film as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com