Rear suspension pull rod structure for connecting power assembly with front sub frame

A front subframe and powertrain technology, which is applied to the power plant, substructure, vehicle components, etc., can solve the problem of insufficient life to meet the design requirements, and achieve the effect of optimizing noise and improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

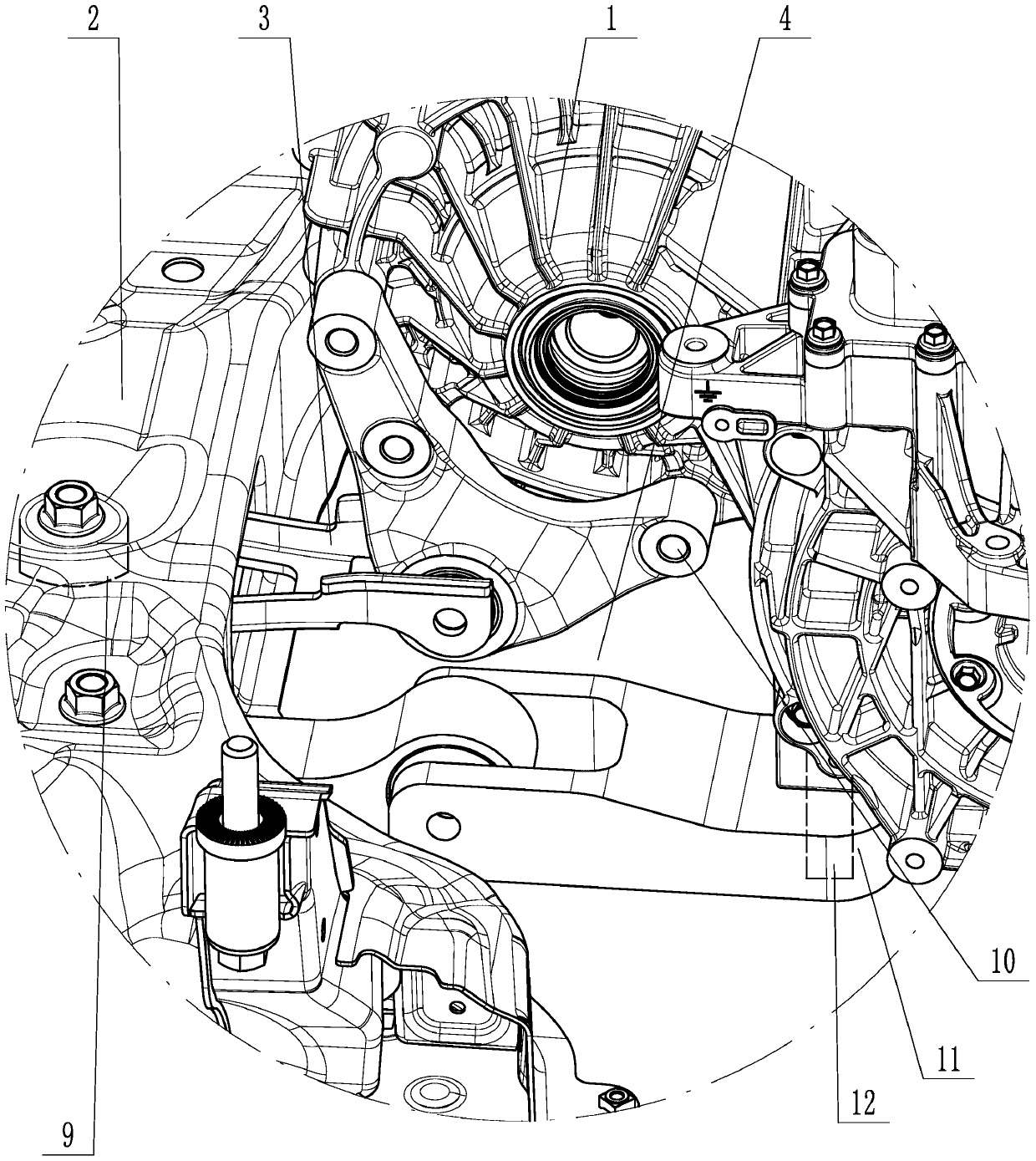

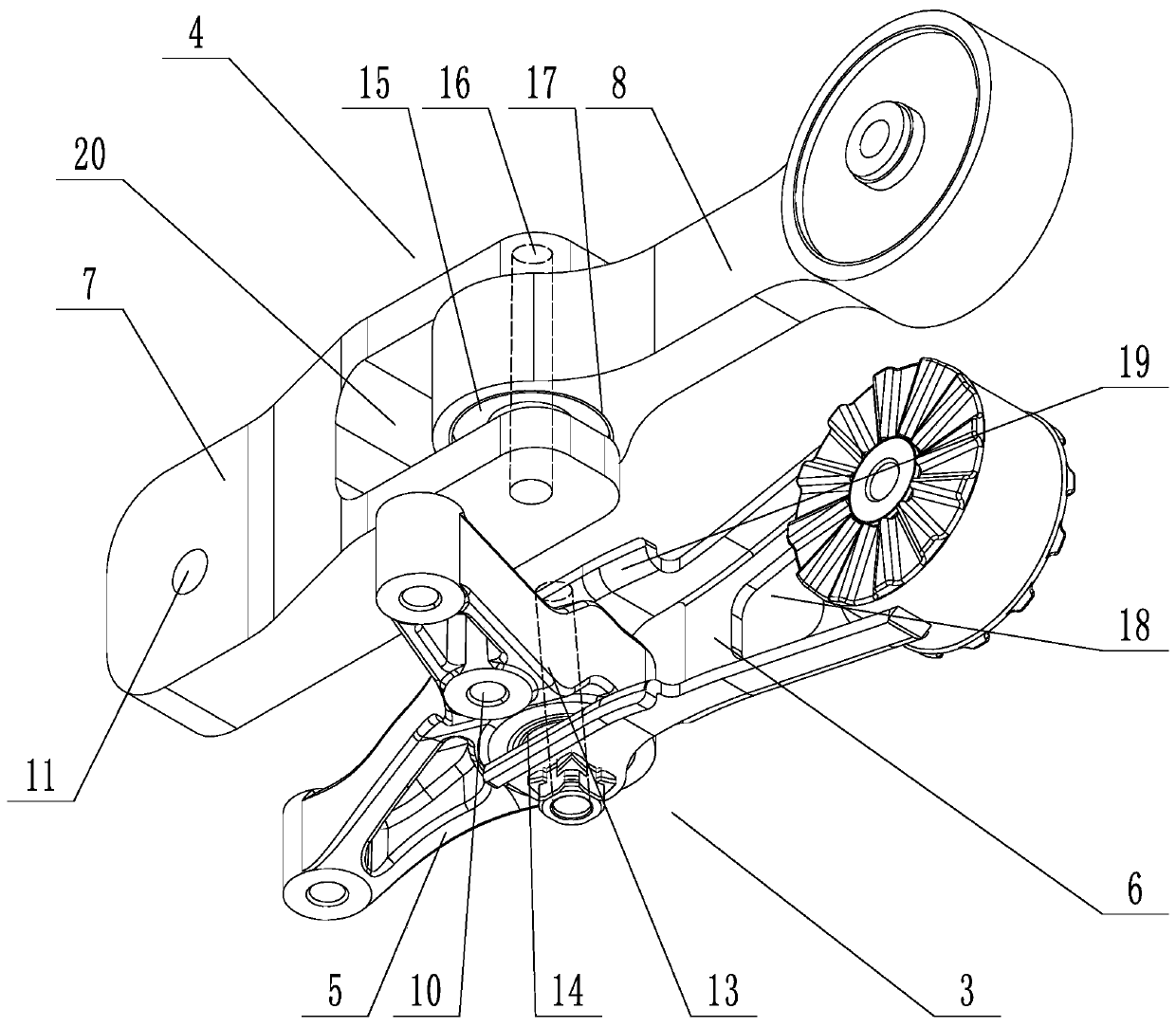

[0025] A rear suspension tie rod structure connected between the power assembly 1 and the front subframe 2, such as figure 1 As shown, it includes a power assembly 1, a front subframe 2 and a connection bracket connected between the power assembly 1 and the front subframe 2, the connection bracket includes a first connection bracket 3 and a second connection bracket 4, the first The connection bracket 3 includes a first rear suspension upper body 5 and a first rear suspension lower body 6, and the second connection bracket 4 includes a second rear suspension such as figure 2 As shown, the suspension upper body 7 and the second rear suspension lower body 8 , the first rear suspension upper body 5 and the second rear suspension upper body 7 are connected to the powertrain 1 .

[0026] The first rear suspension lower body 6 and the second rear suspension lower body 8 are fixedly connected to the front sub-frame 2, and the front sub-frame 2 is provided with buffer bosses 9, the f...

Embodiment 2

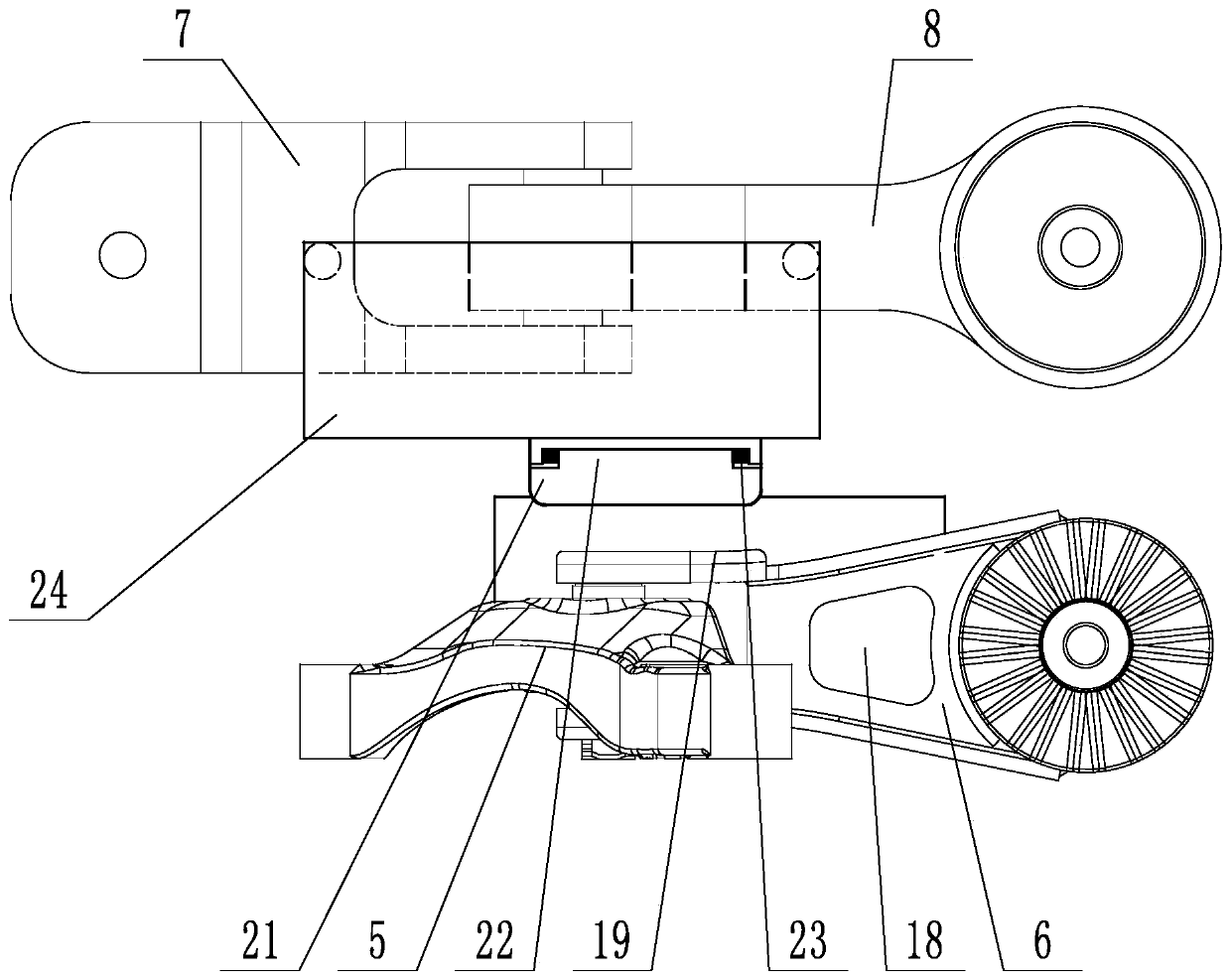

[0031] On the basis of embodiment 1, the present embodiment also includes:

[0032] Such as image 3 and 4 As shown, the energy-absorbing bracket of the first connecting bracket 3 and the second connecting bracket 4, the torsion-resistant bracket includes two twisting blocks 21 that can rotate with each other, the twisting blocks 21 are in the shape of a round cake, and the center of a twisting block 21 is provided with a boss 22. The boss 22 is rotatably inserted in the center of another twist block 21. The two twist blocks 21 are arranged opposite to each other. A torsion spring 23 is hingedly connected between the two twist blocks 21. A vertical connection is provided on the twist block 21. Plate 24 has two connecting plates 24 in total. One connecting plate 24 extends upwards to be higher than the first connecting bracket 3, and the other connecting plate 24 extends downwards to be lower than the second connecting bracket 4. The connecting plate 24 is provided with a corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com