Mobile carrying robot for logistics storage

A robot and warehousing technology, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., can solve the problems of inability to develop or purchase comprehensive, systematic and highly intelligent warehouses, and achieve labor-intensive, high-efficiency, long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

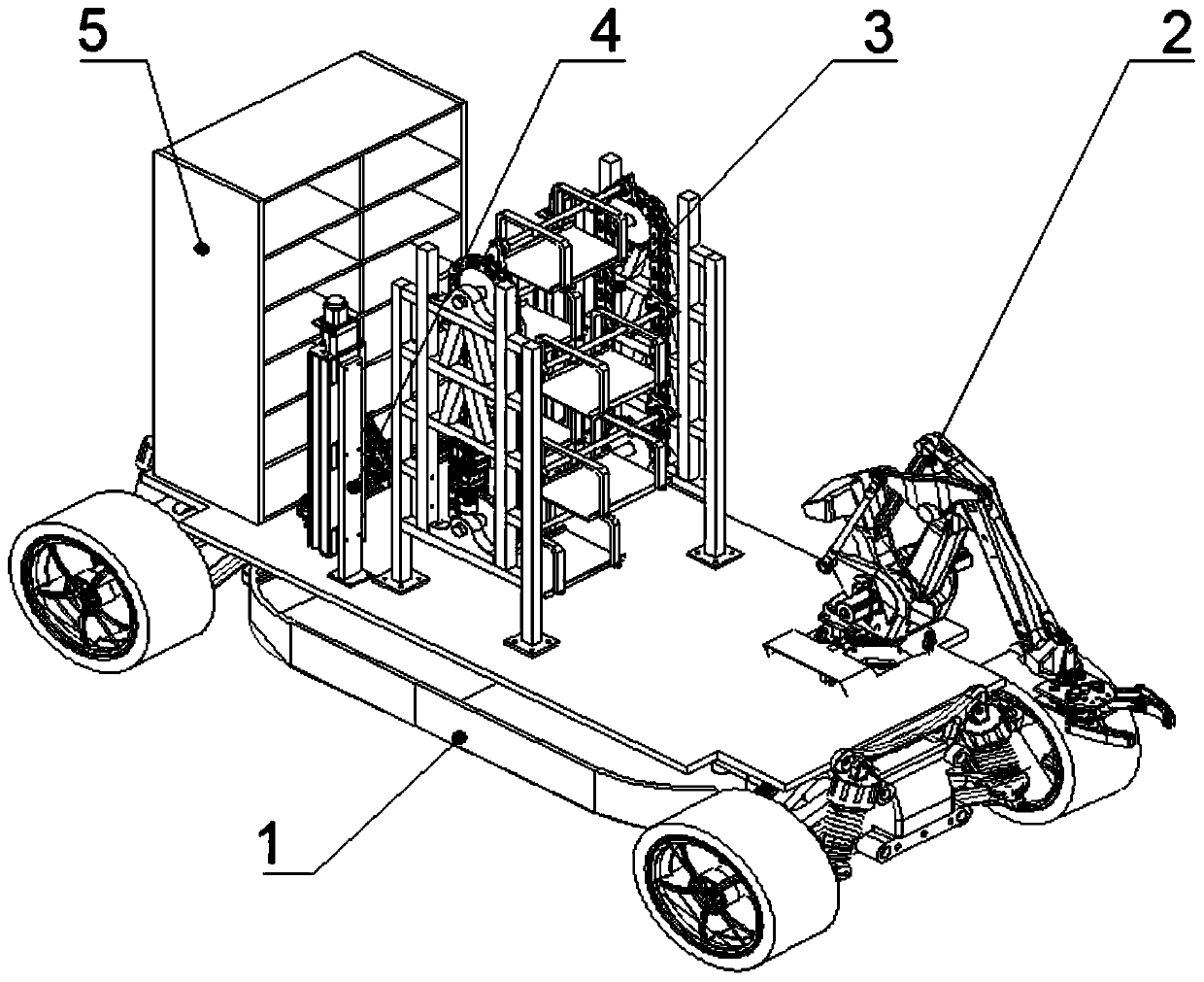

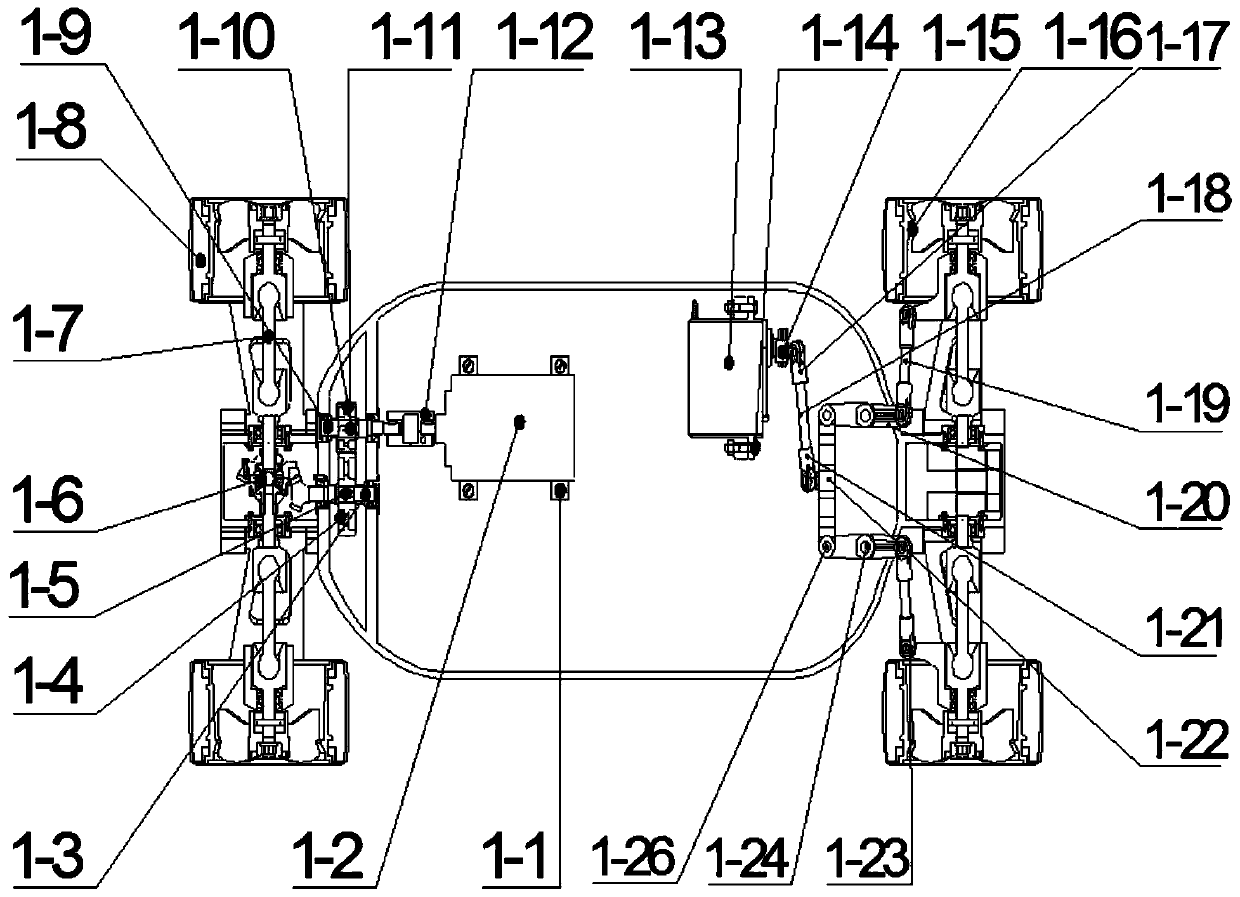

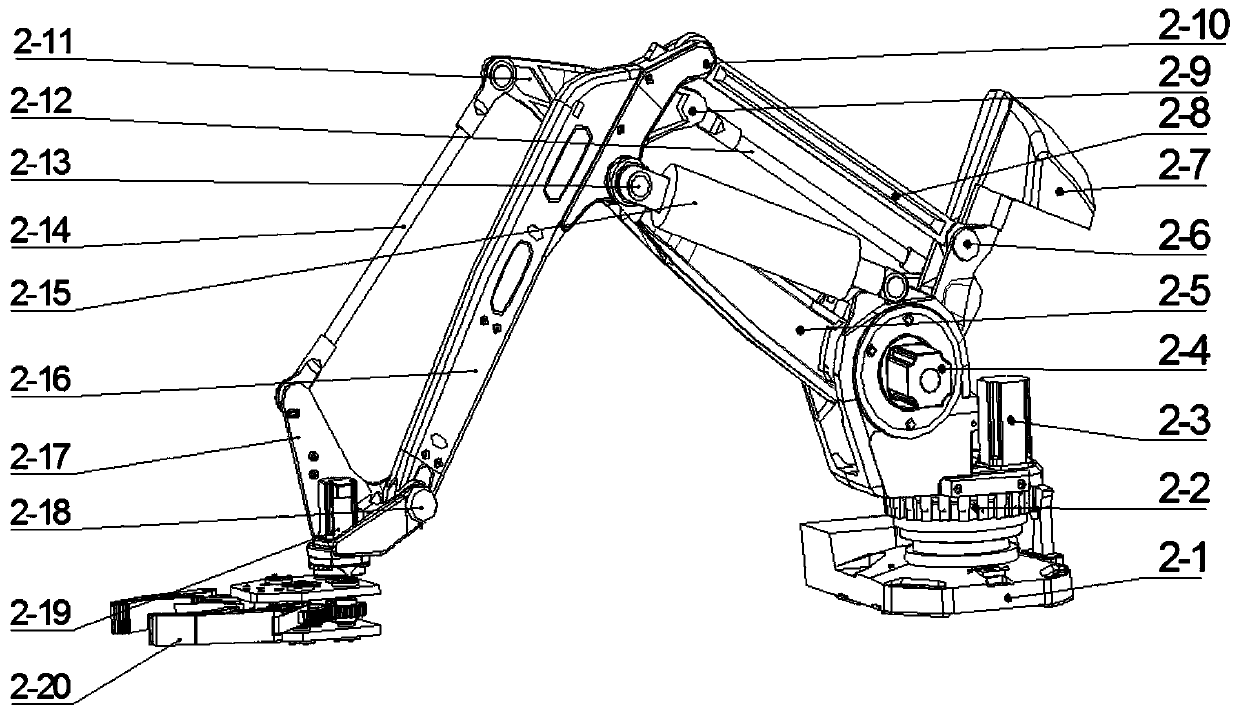

[0023] combine Figure 1 to Figure 7 , a kind of robot that is used for handling of the present invention is made up of chassis assembly 1, large mechanical arm assembly 2, cargo cycle assembly 3, transfer device assembly 4, cargo storage device 5, slotted cylindrical head screw 1-1, motive 1-2 , bevel gear transmission shaft 1-3, large gear 1-4, flat key 1-5, differential 1-6, ball joint transmission shaft 1-7, rear wheel 1-8, shaft 1-9, gear 1- 10. Key 1-11, coupling 1-12, electric steering gear 1-13, slotted cylinder head screw 1-14, rudder handle 1-15, front wheel 1-16, ball shaft head connector 1-17 , Steering connecting rod 1-18, steering connecting rod 1-19, direction turning 1-20, ball shaft head connector 1-21, steering rudder 1-22, ball shaft head 1-23, special bolt 1-24, pin Shaft 1-26, base 2-1, cantilever 2-2, hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com