Device for purifying diesel engine pulses and extracting high-quality nano graphene carbon granules

A technology of diesel internal combustion engine and nano-graphene, which is applied in the direction of graphene, nano-carbon, noise reduction device, etc., can solve the problems such as difficult to achieve emission reduction, DPF blockage, blockage, etc., and achieve the effect of easy cleaning, high utilization rate and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

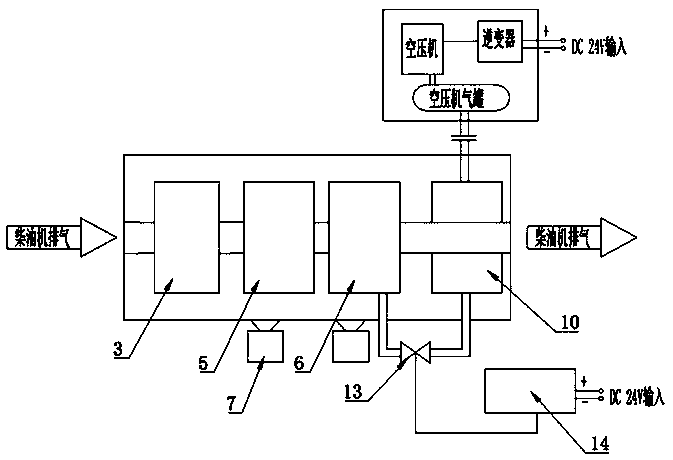

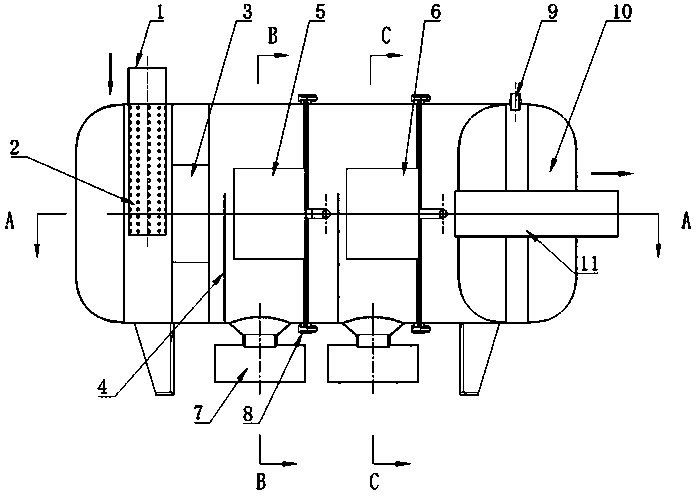

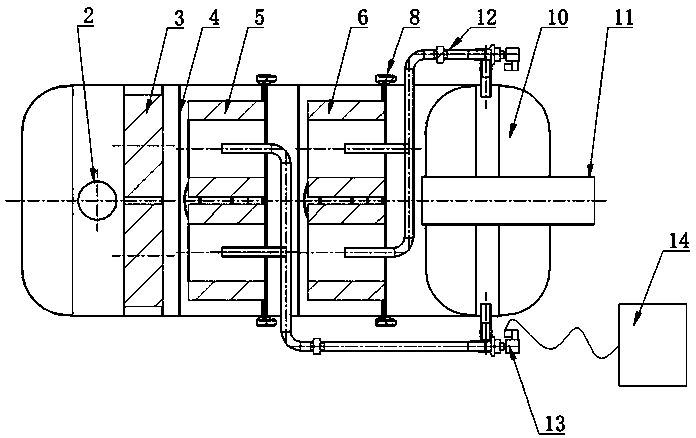

[0021] as attached figure 1 And attached figure 2 As shown, a diesel internal combustion engine pulse purification and extraction of high-quality nano-graphene carbon particles device, including intake pipe 1, intake muffler 2, DOC catalytic unit 3, air flow baffle 4, first-stage stainless steel filter element 5, second-stage Stainless steel filter element 6, carbon particle collector 7, air outlet pipe 11, intake pipe 1 is connected to intake muffler 2, the other end of intake muffler 2 is connected to DOC catalytic unit 3, air flow baffle 4 is located between DOC catalytic unit 3 and the second Between the first-stage stainless steel filter elements 5, the first-stage stainless steel filter element 5 is fixed by a connecting flange 8, and the second-stage stainless steel filter element 6 is connected to the air outlet pipe by a connecting flange. The pulse air pipe 12 is communicated with the first-stage stainless steel filter core 5 and the second-stage stainless steel fi...

Embodiment 2

[0029] The form of shaft in and shaft out is as follows Figure 6 As shown, the inlet pipe 1 and the outlet pipe 11 are located on the horizontal axis on the left and right sides of a diesel internal combustion engine pulse purification and extraction of high-quality nano-graphene carbon particles. All the other are with embodiment 1.

Embodiment 3

[0031] The form of shaft inlet and side outlet is as follows: Figure 7 As shown, the intake pipe 1 is located on the axis of the left end of a diesel internal combustion engine pulse purification and extraction device for high-quality nano-graphene carbon particles. The air outlet pipe 11 is arranged upwards on the right side of a diesel internal combustion engine pulse purification and extraction device for high-quality nano-graphene carbon particles, and exhausts from the right side upwards. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com