Sheet-metal machining production line

A production line and sheet metal technology, applied in the field of sheet metal processing, can solve the problems of inconvenient transportation, high labor intensity and low processing efficiency, and achieve the effect of reducing handling operations and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

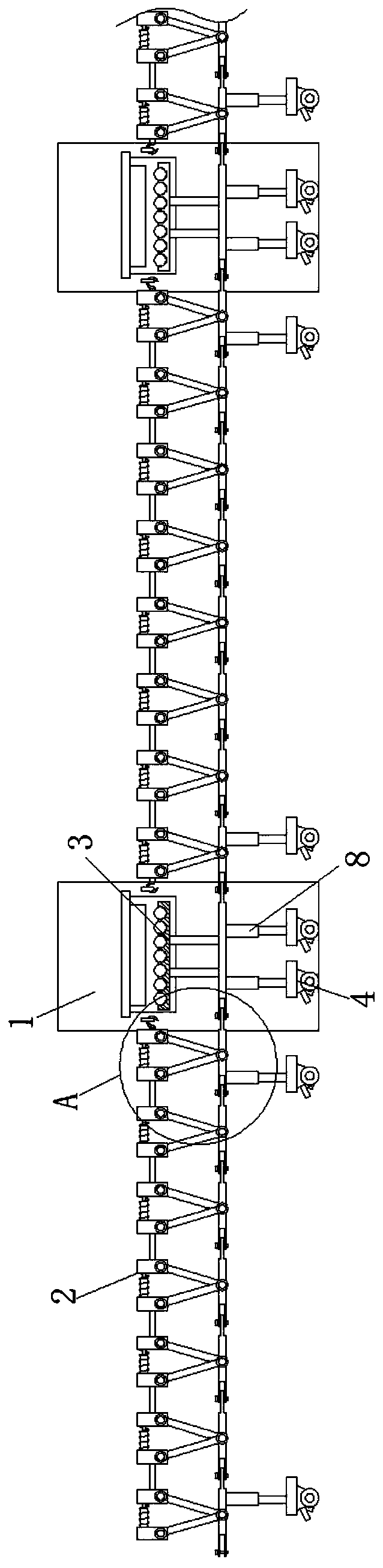

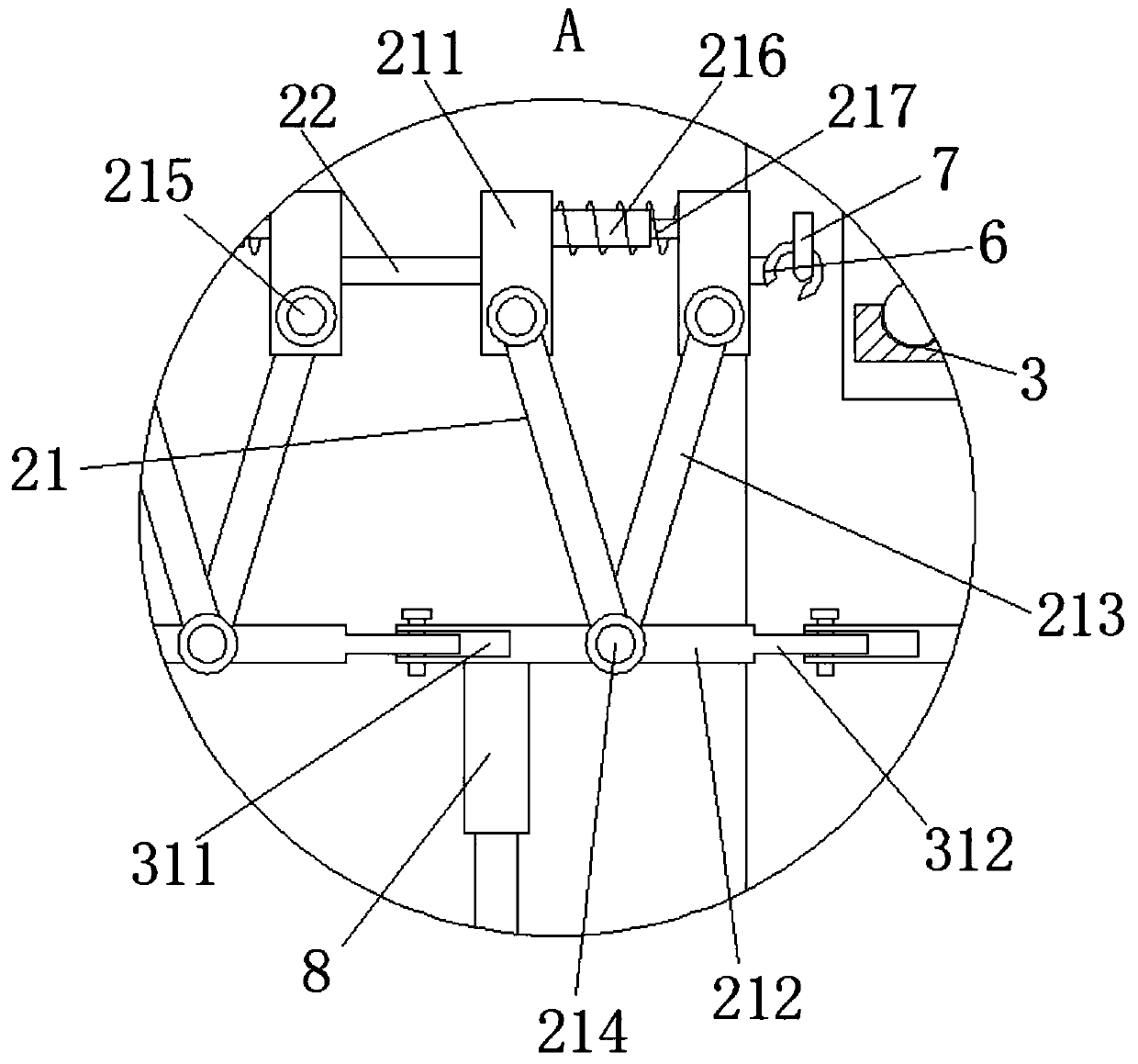

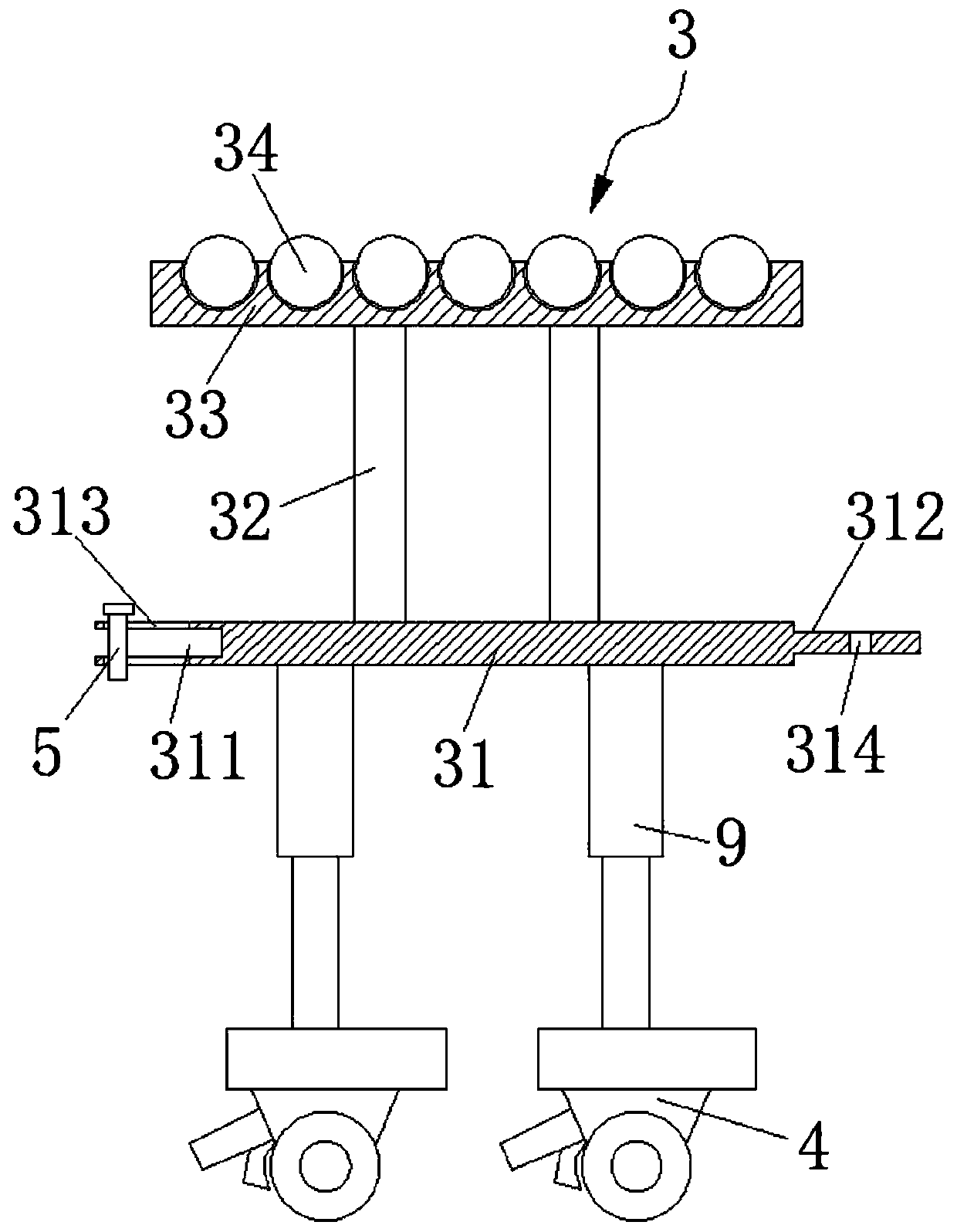

[0025]As an embodiment of the present invention, the transmission mechanism 2 is composed of a transmission assembly 21, a rubber rod 22 and a caster with lock 4. Two transmission assemblies 21 are connected by a rubber rod 22, and four belts are arranged on the lower side of the transmission assembly 21. Locking caster 4, band lock caster 4 is used to facilitate the movement of transmission mechanism 2; Transmission assembly 21 comprises mounting block 211, connecting plate 212, connecting rod 213, connecting shaft 214, rotating shaft 215, motor, telescopic rod 216 and spring 217; Two The two mounting blocks 211 are connected by telescopic rods 216, and the telescopic rods 216 are sleeved with springs 217, and the springs 217 are arranged between the two mounting blocks 211, and the two mounting blocks 211 at the front and rear are rotatably connected with a rotating shaft 215. The end is fixedly connected with the output shaft of the motor, and the motor is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com