Warp knitting machine feeding mechanism tensioning device

A tensioning device and warp knitting machine technology, which is applied in the field of warp knitting machine feeding, can solve problems such as wrinkles, fabric breakage, and fabric output speed changes, and achieve the effects of good elasticity, fast rotating shaft speed, and reduced external force changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

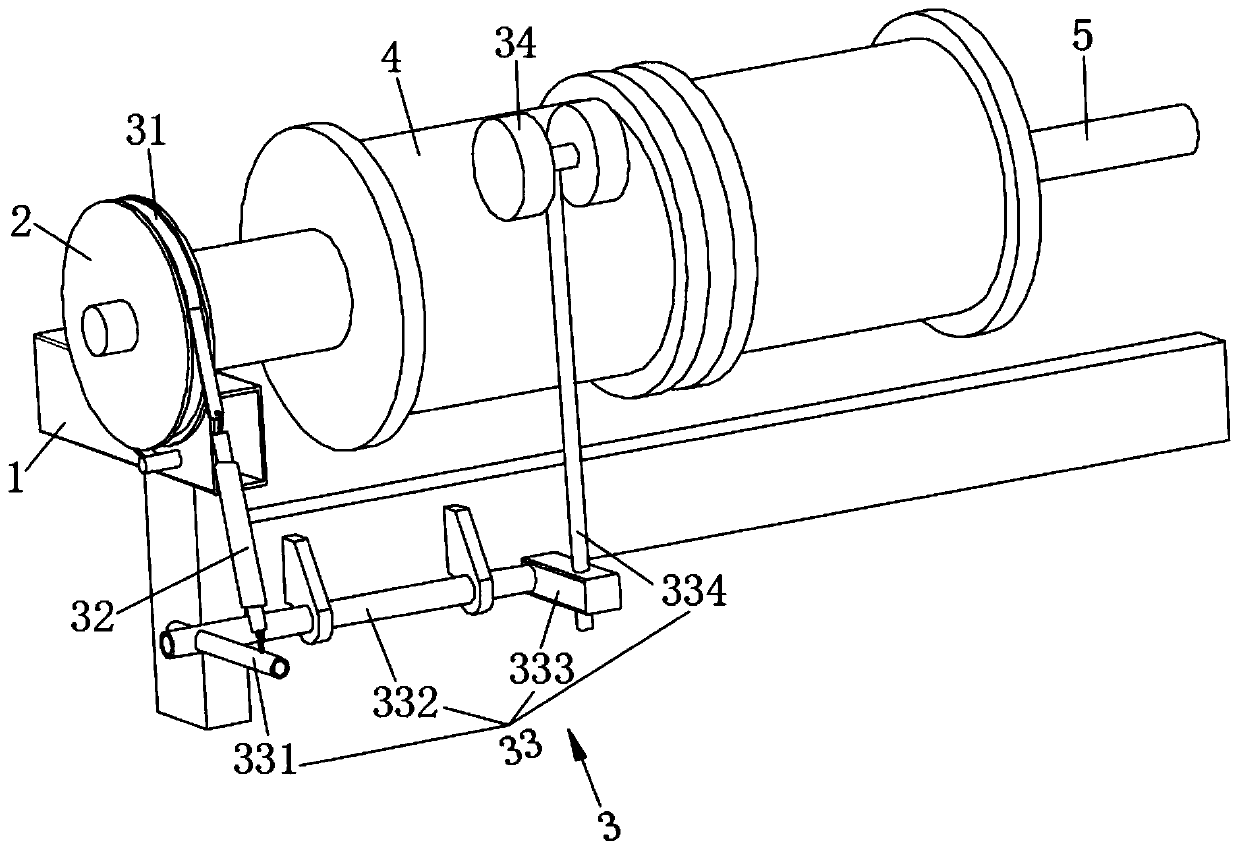

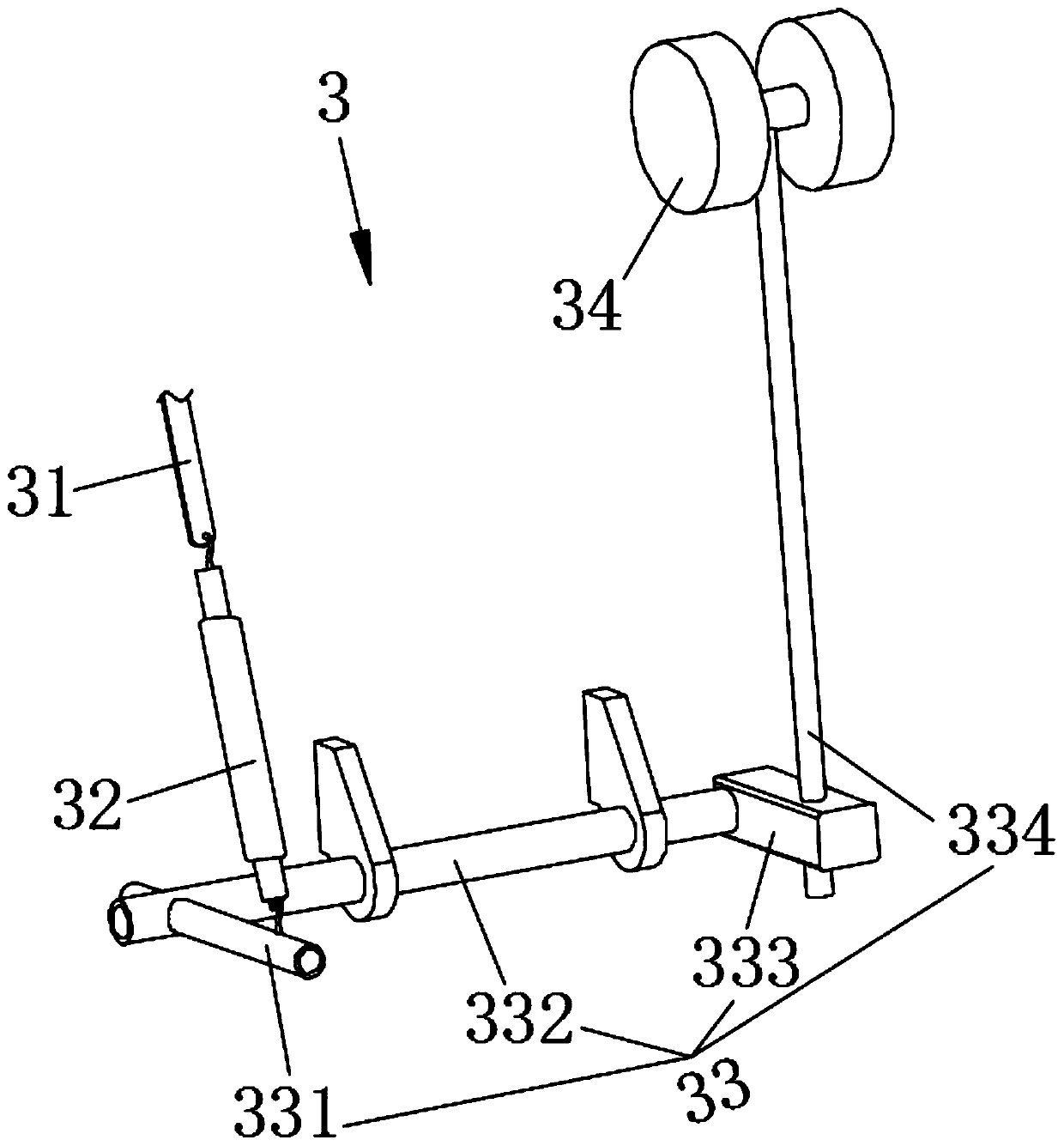

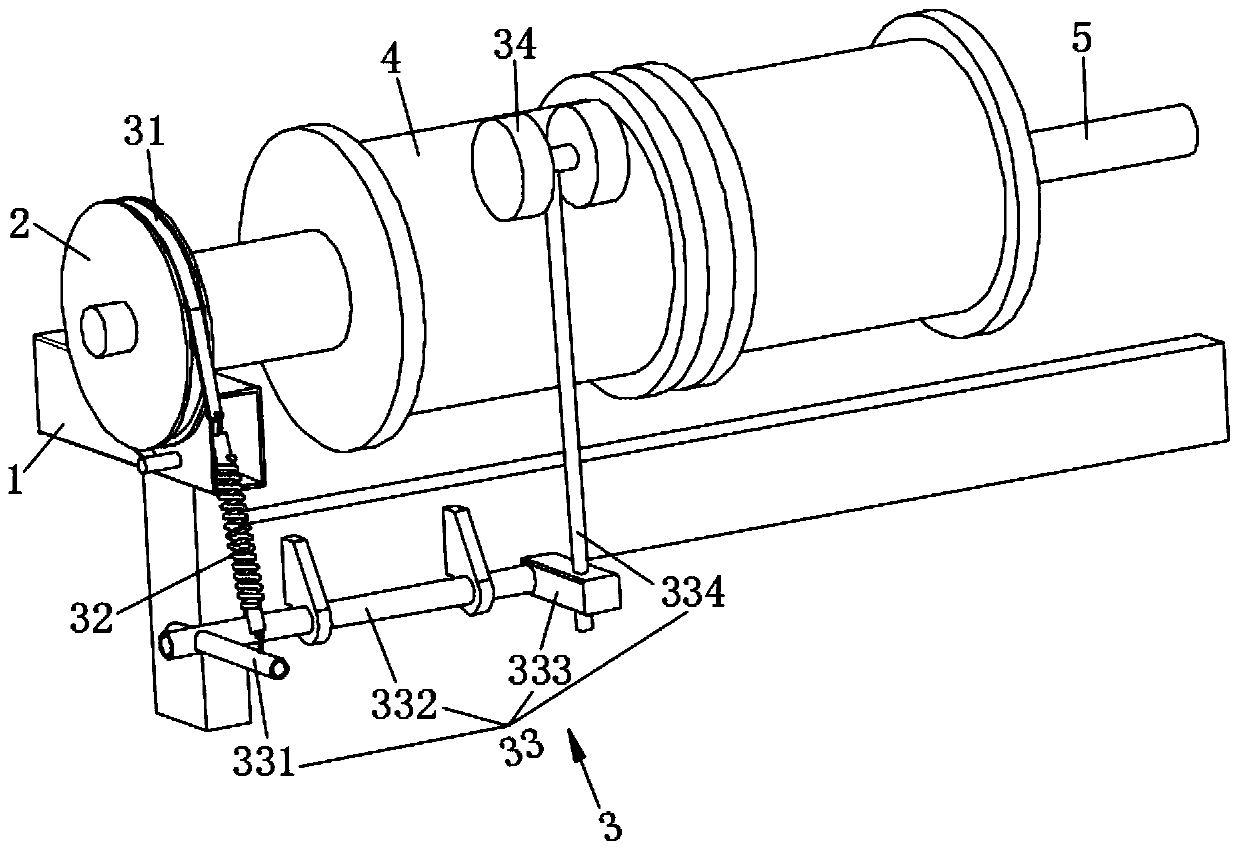

[0026] refer to figure 1 , this embodiment discloses a tensioning device for a feeding mechanism of a warp knitting machine, including a bracket 1 , a speed regulating disk 2 , a tensioning conduction assembly 3 , a feeding roller 4 and a rotating shaft 5 . The rotating shaft 5 is arranged on the bracket 1 . The feeding roller 4 is sleeved on the rotating shaft 5 . One end of the tension conduction assembly 3 capable of adjusting the rotational speed of the speed regulating disk 2 is connected to the speed regulating disk 2 , and the other end is in contact with the feeding roller 4 .

[0027] The rotating shaft 5 is rotatably fitted with a fixed sleeve, and the fixed sleeve is installed on the bracket 1 .

[0028] The rotating shaft 5 drives the feeding roller 4 to rotate, the cloth on the feeding roller is reduced, the radius of the cylinder formed by the cloth is reduced, and the output linear speed is reduced. The rotation speed of the cloth is accelerated with the redu...

Embodiment 2

[0036] The elastic connector 32 is a compressed air cylinder (not shown in the figure). The compressed gas cylinder includes a cylinder body (not shown in the figure) and a push rod (not shown in the figure) arranged in the cylinder body. The output end of the push rod is connected to the first connecting pipe 331 . The cylinder is connected to the elastic resistance piece 31 .

[0037] When the amount of cloth wound on the feeding roller 4 increases, the second connecting pipe 334 rotates, and the first connecting pipe 331 is driven to rotate through the connecting shaft 332, and then the push rod is pulled out from the cylinder to form a negative pressure in the cylinder; When the cloth wound on the roller 4 decreases, the negative pressure formed in the cylinder will draw back the push rod. When the cloth increases or decreases, the positive and negative pressure formed by the cylinder will increase or decrease the frictional force between the elastic resistance sheet 31 ...

Embodiment 3

[0039] refer to image 3 The difference between the second embodiment and the first embodiment is that the elastic connecting member 32 is a spring. When one end of the spring is subjected to an external force, under the action of its elasticity, the change range of the external force at the other end decreases, and the vibration amplitude of the components connected to the other end decreases, which effectively prevents the elastic resistance sheet 31 from falling off due to severe external impact force , secondly, the spring has good elasticity and simple structure, and the elastic connector 32 is made of spring, which has the highest comprehensive cost performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com