Hydroenergy machine power generation system without construction of barrage

A technology of power generation system and hydropower generator, which is applied in the fields of hydropower generation, electromechanical devices, machines/engines, etc., can solve the problems of resettlement work costs, time-consuming, difficult construction, and large construction investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

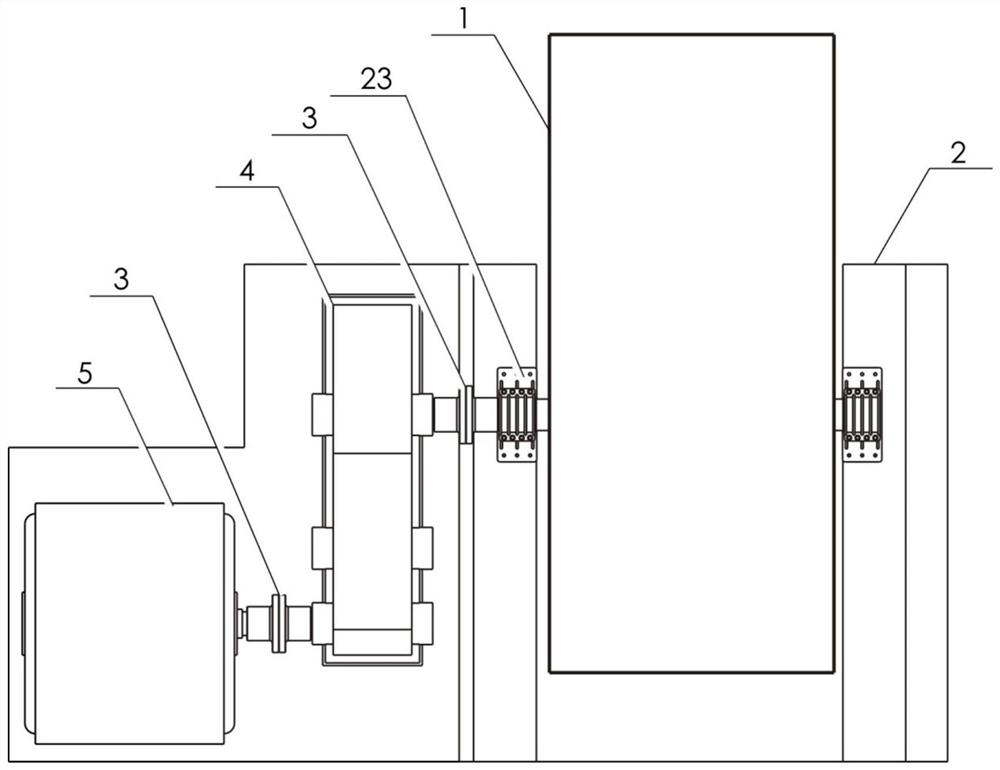

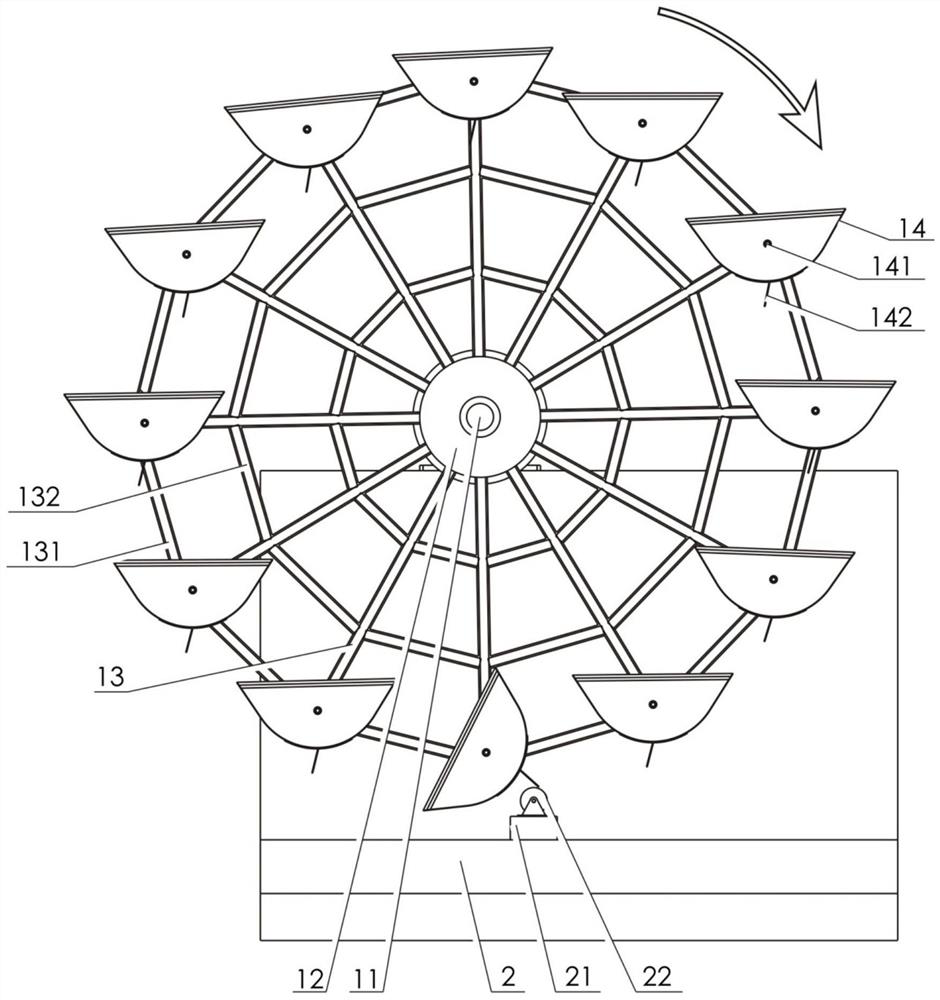

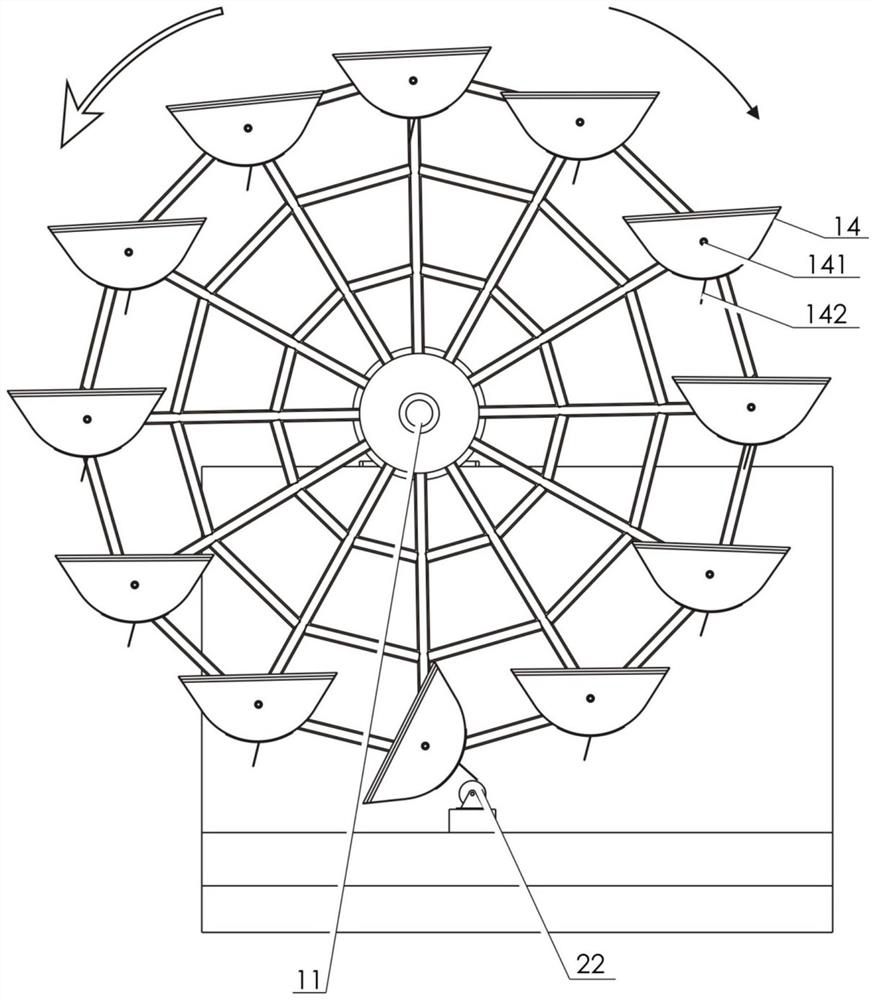

[0019] Such as figure 1 with figure 2 As shown, the present invention does not need to build the embodiment of the water energy machine power generation system of the barrage, including the water energy machine 1, the mounting seat 2, the coupling 3, the transmission 4 and the generator 5, and the water energy machine 1 is erected on the installation through the bearing seat 23 In the seat 2, the transmission 4 is connected to the rotating shaft 11 of the water energy machine 1 through a coupling 3, and the generator 5 is connected to the transmission 4 through a coupling 4; the water energy machine 1 includes a rotating shaft 11, a rotating device, and a bucket 14 , the rotating device is installed on the rotating shaft 11, the periphery of the rotating device is evenly connected with a water bucket 14, the water bucket 14 is connected with the spok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com