Opening and picking machine

A technology of opening and cleaning machines and cleaning cotton, which is applied in the field of textile machinery manufacturing, which can solve the problems of difficulty in meeting the requirements of the carding machine, limiting the output of opening and cleaning cotton, and insufficient pressure in the cotton box, so as to achieve stable pressure and increase storage capacity. Cotton amount and noil smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing:

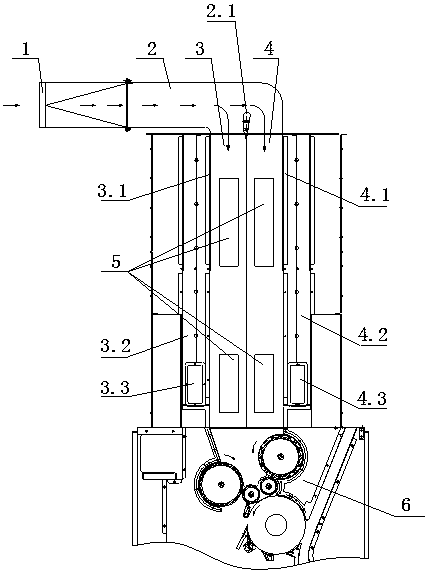

[0017] see figure 1 , the embodiment of a double cotton storage box of a cotton opening and cleaning machine of the present invention, comprising: a feeding port 1, a cotton delivery pipeline 2, a cotton storage box, an exhaust system and a cotton box window, and there are two cotton storage boxes, They are the first cotton storage box 3 and the second cotton storage box 4 respectively. The two cotton storage boxes are arranged side by side. Both are in communication with the cotton opening and cleaning machine 6; the first cotton storage box 3 and the second cotton storage box 4 are respectively equipped with mutually independent dust filter exhaust systems.

[0018] The above-mentioned dust filter exhaust systems of the first cotton storage box 3 and the second cotton storage box 4 all include a cotton box exhaust mesh plate, a dust filter chamber and a dust fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com