Special-shaped tube for looms and application thereof to water-jet or air-jet looms

A special-shaped tube and loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of low production efficiency and equipment wear and tear, and achieve the effects of low production efficiency, improved production efficiency and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

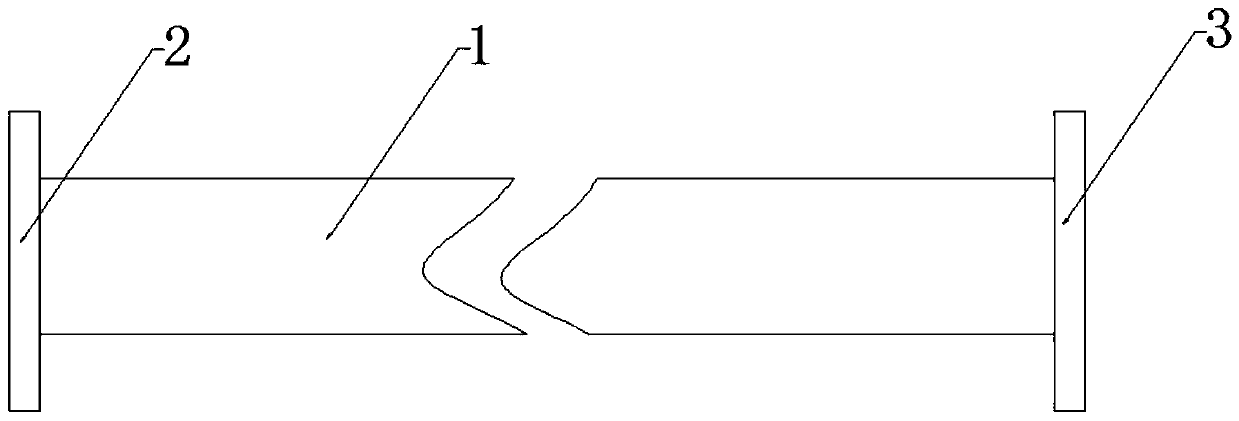

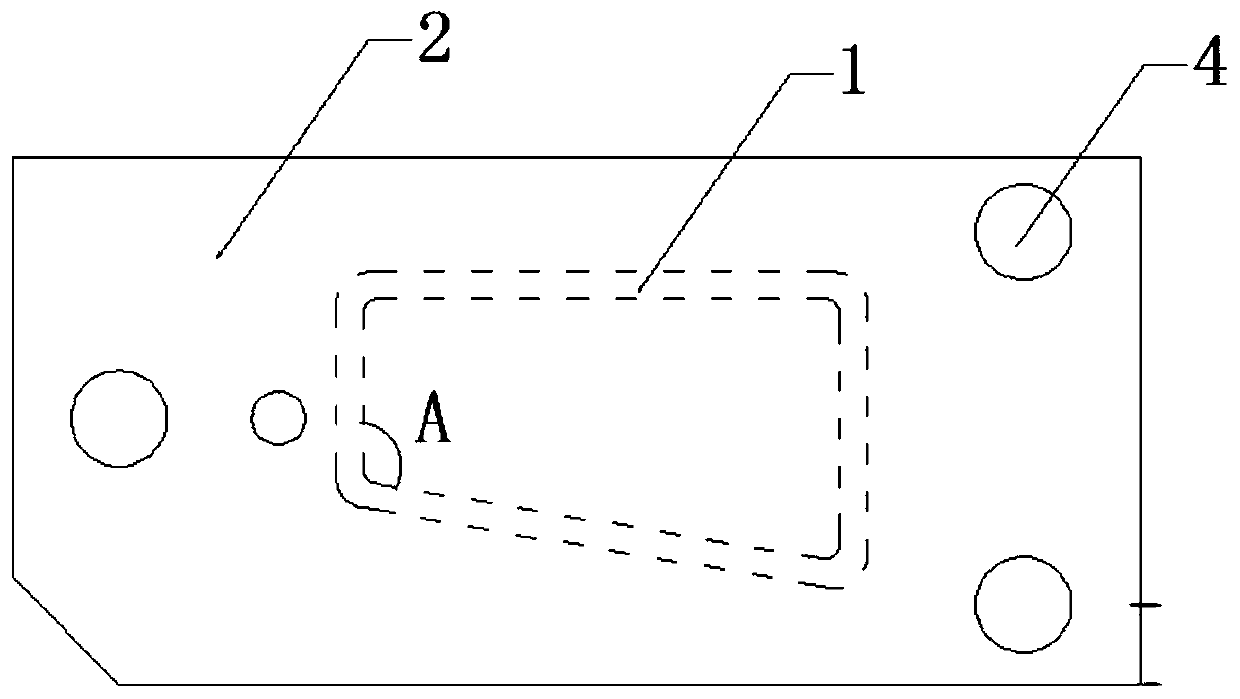

[0031] Such as figure 1 with figure 2 As shown, a special-shaped pipe for a loom of the present invention includes a seamless steel pipe body 1, a left connecting flange 2 and a right connecting flange 3, the cross section of the seamless steel pipe body 1 is a polygonal special-shaped cross section, and the The left connecting flange 2 and the right connecting flange 3 are respectively fixed on the left and right sides of the seamless steel pipe body 1 by welding, and the left connecting flange 2 and the right connecting flange 3 are both provided with bolt mounting holes 4, and the A sealed space is formed between the left connecting flange 2 , the right connecting flange 3 and the lumen of the seamless steel pipe body 1 .

[0032] Further, the cross section of the seamless steel pipe body 1 is quadrilateral.

[0033] Further, the cross section of the seamless steel pipe body 1 is trapezoidal.

[0034] Further, the cross-section of the seamless steel pipe 1 is a right-an...

Embodiment 2

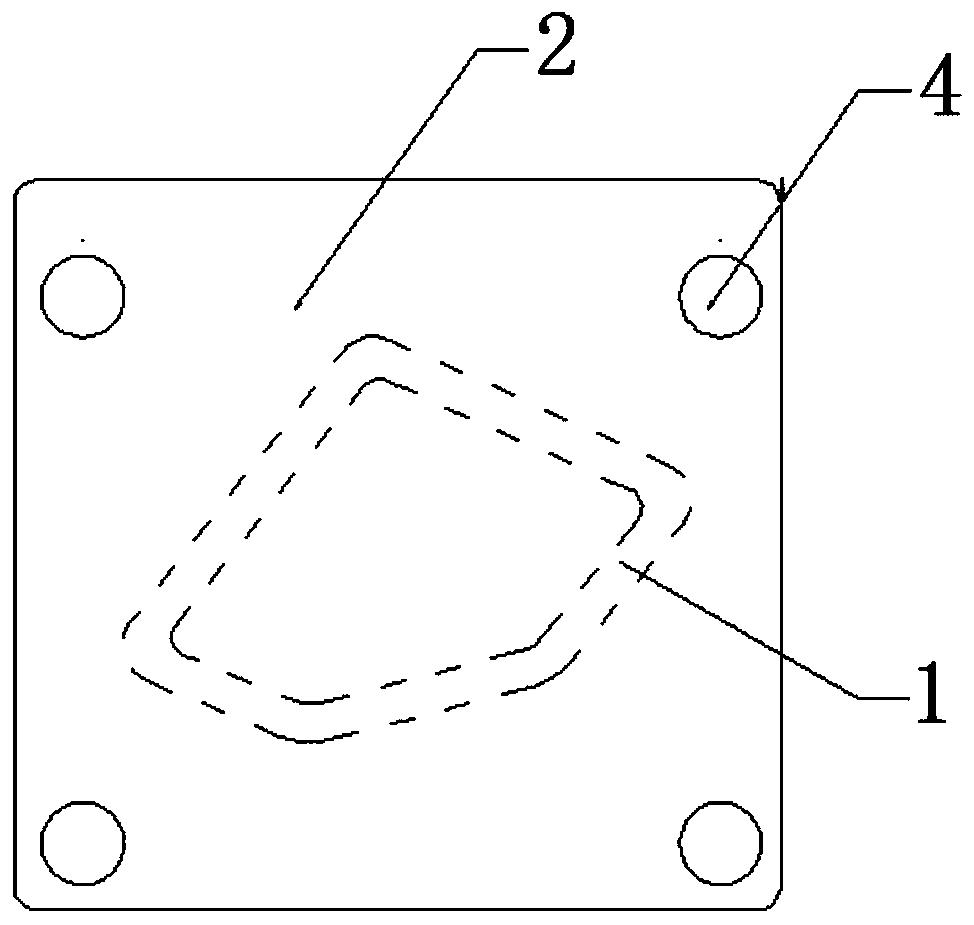

[0041] Such as figure 1 with image 3 As shown, a special-shaped pipe for a loom includes a seamless steel pipe body 1, a left connecting flange 2 and a right connecting flange 3, the cross section of the seamless steel pipe body 1 is a polygonal special-shaped cross section, and the left connecting flange The flange 2 and the right connecting flange 3 are respectively fixed on the left and right sides of the seamless steel pipe body 1 by welding, the left connecting flange 2 and the right connecting flange 3 are all provided with bolt mounting holes 4, and the left connecting flange A sealed space is formed between the flange 2 , the right connecting flange 3 and the lumen of the seamless steel pipe body 1 .

[0042] Further, the cross section of the seamless steel pipe body 1 is pentagonal.

[0043] Further, the cross-section of the seamless steel pipe body 1 is a convex pentagon.

[0044] Further, the seamless steel pipe body 1, the left connecting flange 2 and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com