Full cross-section grouting pipe device

A technology of full-section grouting pipes and grouting pipes, which is applied in the direction of hoses, pipes, pipe supports, etc., can solve problems such as water seepage, and achieve the effects of high efficiency, convenient operation, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

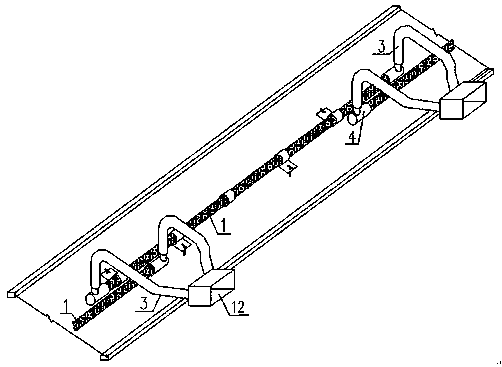

[0036] see figure 1 and Figure 6 , a full-section grouting pipe 1 device, including a grouting pipe 1 arranged in a construction joint, a connecting pipe 4 respectively arranged at two ends of the grouting pipe 1, a grouting conduit 3 connected to the outer end of the connecting pipe 4 at one end, and A grouting box 12 connected to the other end of the grouting conduit 3, a number of grouting pipes 1 are connected head to tail through the fixing piece 1-1, and the connecting pipe 4 is sheathed on the end of the grouting pipe 1;

[0037] The fixing part 1-1 includes a horizontal column and a flat plate horizontally arranged at the bottom of the column, the flat plate is fixed on the concrete, and the ends of the two grouting pipes are adjacent and both are arranged in the column;

[0038] More preferably, a screw 1-3 is vertically arranged on the top of the drum, and the screw 1-3 passes through the threaded hole provided at the upper end of the cylinder, and the contact join...

Embodiment 2

[0049] see figure 1 and Figure 6 , a full-section grouting pipe 1 device, including a grouting pipe 1 arranged in a construction joint, a connecting pipe 4 respectively arranged at two ends of the grouting pipe 1, a grouting conduit 3 connected at one end to two ends of the connecting pipe 4, and A grouting box 12 connected to the other end of the grouting conduit 3, a number of grouting pipes 1 are connected end to end through the fixing piece 1-1, and the connecting pipe 4 is set on the end of the grouting pipe 1;

[0050] The fixing part 1-1 includes a horizontal column and a flat plate horizontally arranged at the bottom of the column, the flat plate is fixed on the concrete, and the ends of the two grouting pipes are adjacent and both are arranged in the column;

[0051] More preferably, a screw 1-3 is vertically arranged on the top of the drum, and the screw 1-3 passes through the threaded hole provided at the upper end of the cylinder, and the contact joint of two adj...

Embodiment 3

[0062] see figure 1 and Figure 6 , a full-section grouting pipe 1 device, including a grouting pipe 1 arranged in a construction joint, a connecting pipe 4 respectively arranged at two ends of the grouting pipe 1, a grouting conduit 3 connected at one end to two ends of the connecting pipe 4, and A grouting box 12 connected to the other end of the grouting conduit 3, a number of grouting pipes 1 are connected end to end through the fixing piece 1-1, and the connecting pipe 4 is set on the end of the grouting pipe 1;

[0063] The fixing part 1-1 includes a horizontal column and a flat plate horizontally arranged at the bottom of the column, the flat plate is fixed on the concrete, and the ends of the two grouting pipes are adjacent and both are arranged in the column;

[0064] More preferably, a screw 1-3 is vertically arranged on the top of the drum, and the screw 1-3 passes through the threaded hole provided at the upper end of the cylinder, and the contact joint of two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com