Irregular sample thermal conductivity test method

A test method and technology of thermal conductivity, which is applied in the field of thermal conductivity testing of irregular samples, and can solve problems such as irregular shapes and uneven materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the test object has an irregular shape, and the material may be uneven, and its thermophysical properties are similar to those of ceramic materials. If conventional testing methods are used, it is difficult to non-destructively construct a heat transfer conforming to the test model, so its thermal conductivity cannot be tested.

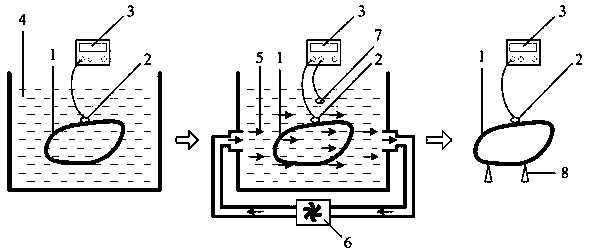

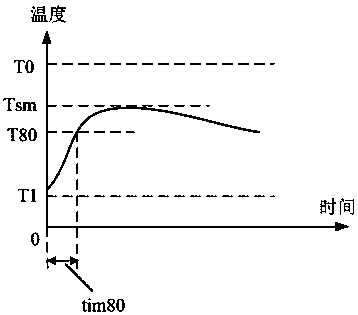

[0030] The test method of this embodiment is as figure 1 As shown, a thermocouple 2 is fixed on the surface of the sample 1 to be tested, and the thermocouple 2 is connected to a temperature measuring instrument 3 to sample and record temperature data; in addition, a thermocouple 7 and a sample holder 8 are connected to the temperature measuring instrument 3 for measuring and recording the ambient temperature during the test . The testing process mainly includes three steps:

[0031] Step 1: Place the sample 1 to be tested in a constant temperature water bath 4 at a temperature of "room temperature + 20°C" for 1 hour, and ...

Embodiment 2

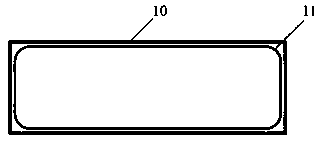

[0041] In this embodiment, the test object is a square lithium battery with a metal shell, and its irregular characteristics are mainly manifested in the macroscopic inhomogeneity, and its structure is as follows: image 3 As shown: the battery is composed of a metal shell 10 and an inner core 11 , and the inner core 11 is completely wrapped and sealed by the metal shell 10 . When the battery is in operation, the inner core 11 will generate heat, which needs to be transferred to the outer surface of the battery (that is, the outer surface of the metal casing 1 ) before it can be further transferred away through air or water circulation. The thermal conductivity of the heat from the inner core 11 to the outer surface of the metal shell 10 is very important to the thermal design. If the package of the lithium battery is not damaged, the heating and temperature measurement in the conventional test method are all on the metal shell 10, and the heat transfer mainly occurs on the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com