Ball guide rail mold of battery capacitor sealing end cover

A technology for sealing end caps and battery capacitors, which is applied to battery caps/end caps, small-sized batteries/battery packs, capacitors, etc. It can solve the problems of not being able to be sealed and fixed, achieve good sealing and fixing, and ensure that the size is qualified The effect of improving the efficiency and improving the pull-off resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

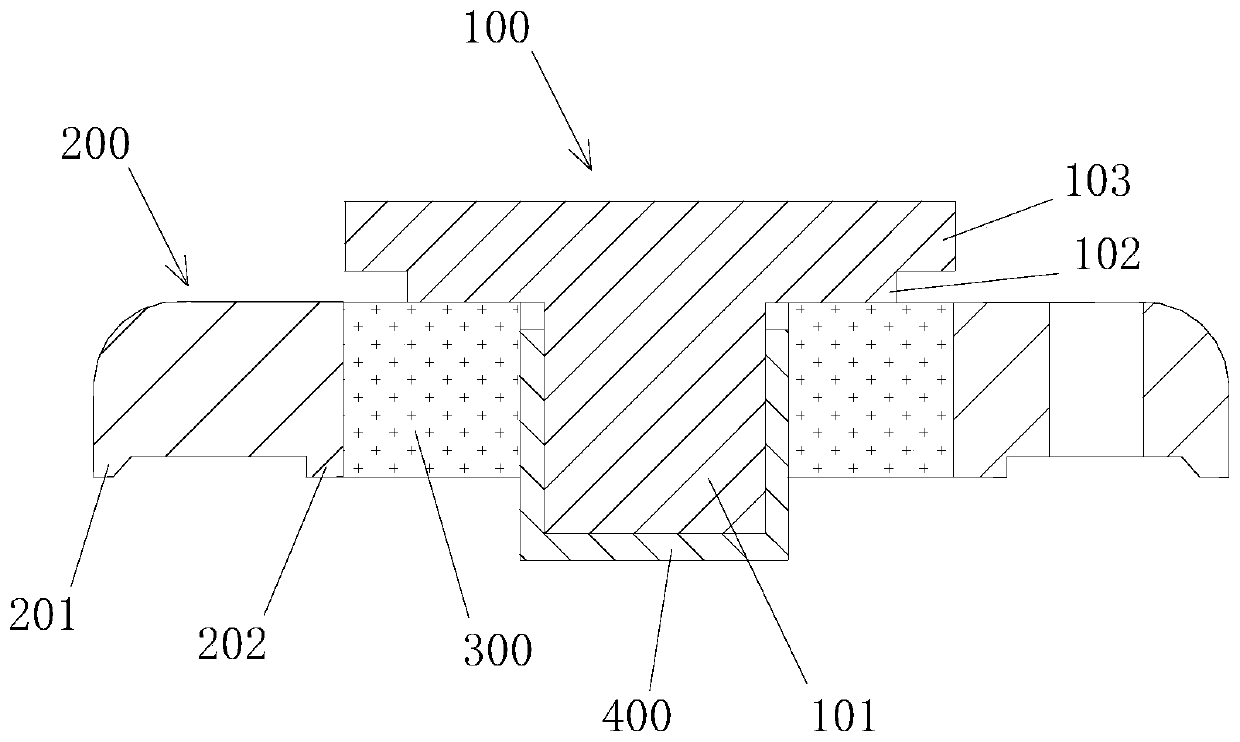

[0027] A ball guide rail mold for the sealed end cap of a battery capacitor, such as figure 1 As shown, the sealing end cap includes a substrate 200 and an electrode 100 , and the substrate 200 and the electrode 100 are assembled through a blank 300 and a metal sleeve 400 .

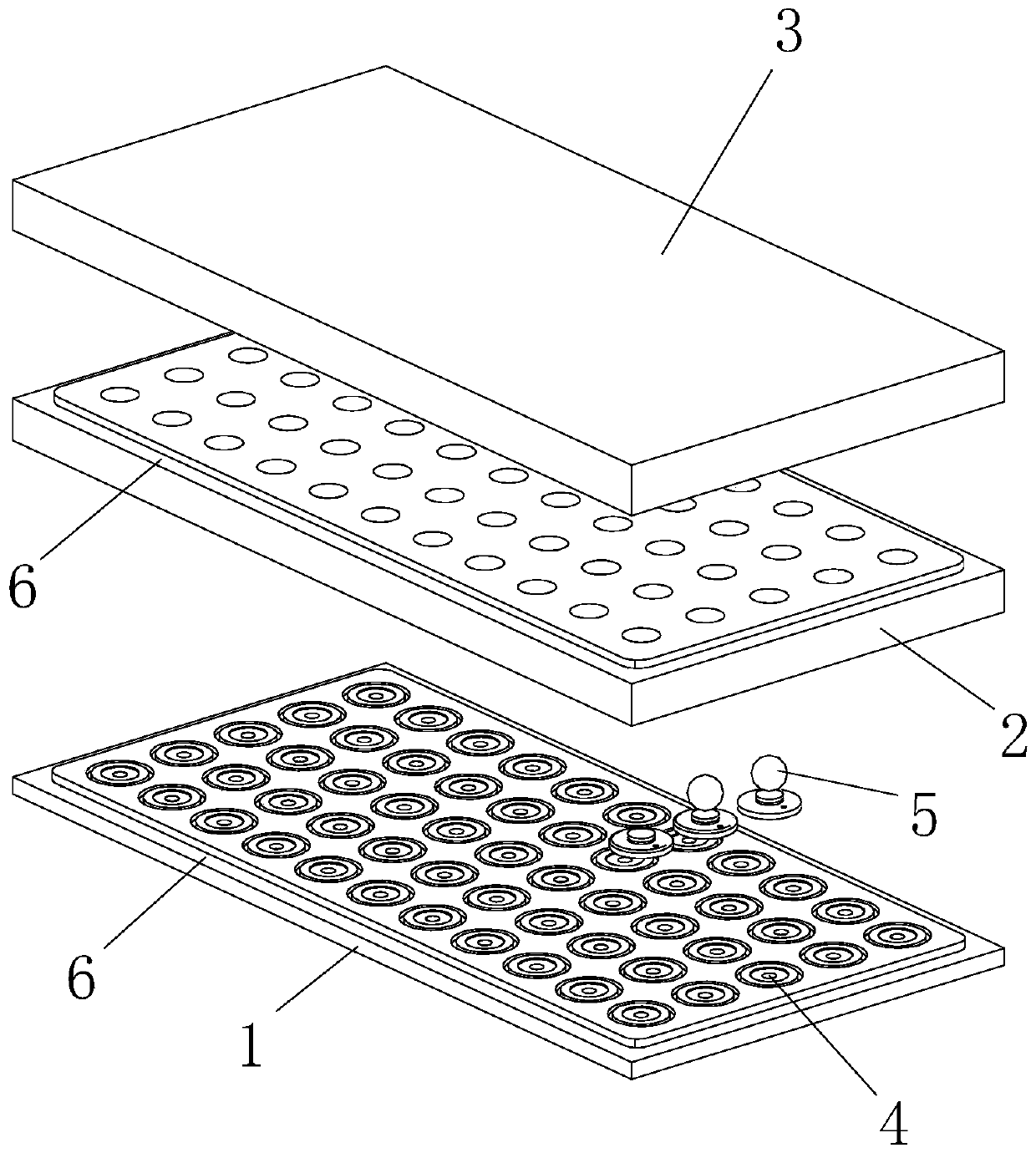

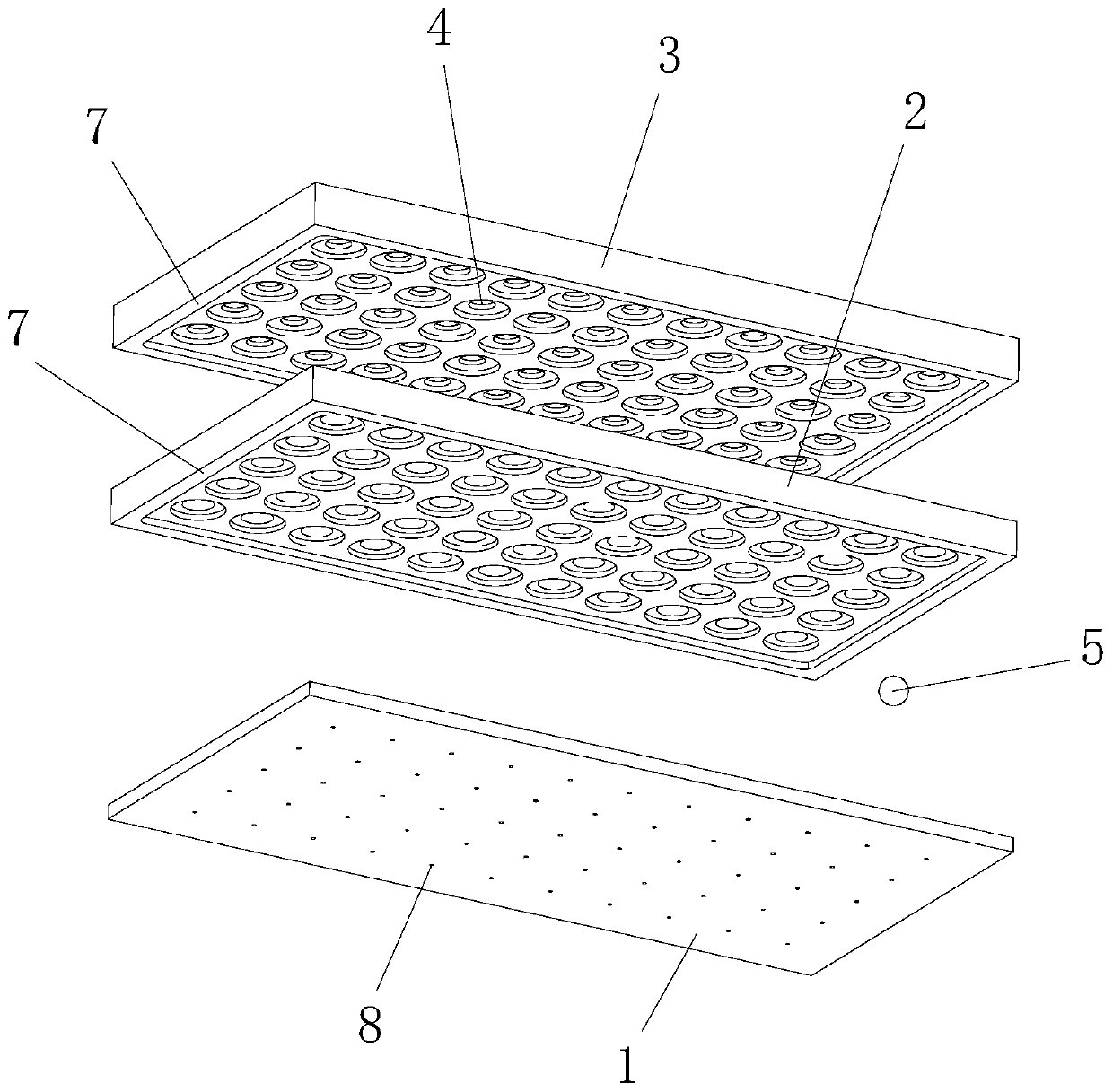

[0028] recombine Figure 2 to Figure 5 As shown, the ball guide rail mold is composed of the lower plate mold 1, the middle plate guide rail mold 2 and the upper cover plate mold 3. The inside of the ball guide rail mold is hollowed out to form a matrix-arranged workpiece placement area 4, and the bottom of the workpiece placement area 4 It is used to place the assembled sealing end cover workpiece, the shape of the bottom of the workpiece placement area 4 and the shape of the sealing end cover (for the specific assembly structure, refer to figure 1 and background technology introduction), so that the workpiece will not shake during the sintering and transportation process. And, each workpiece placement...

Embodiment 2

[0038] A guide post guide rail mold for sealing end caps, the main structure of which is the same as that of embodiment 1, the only difference is that the ball 5 is replaced by a guide post 9, and the bottom of the guide post 9 is made into a hemispherical structure. combine Figure 7 As shown, what is shown is that the workpiece is pressed and fixed by the self-weight of the guide post 9 .

[0039] Also, combine Figure 8 and Figure 9 As shown, the bottom of the above-mentioned guide post 9 is not necessarily a hemispherical structure, and other similar Figure 8 and Figure 9 Structure.

[0040] like Figure 10 As shown, the above-mentioned upper cover plate mold 3 can also be provided with vent holes 8 for further increasing the effect of ventilation and exhaust. The aperture of the vent hole 8 of the upper cover plate mold 3 is smaller than the diameter of the sphere 5 or the guide post 9 to prevent the sphere 5 or the guide post 9 from falling off from the vent hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com