Plasma processing system with faraday shielding device

A technology of Faraday shielding and plasma, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of reduced wafer surface uniformity, reduced plasma processing system life cycle, and inability to clean the dielectric window, etc., to reduce the failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

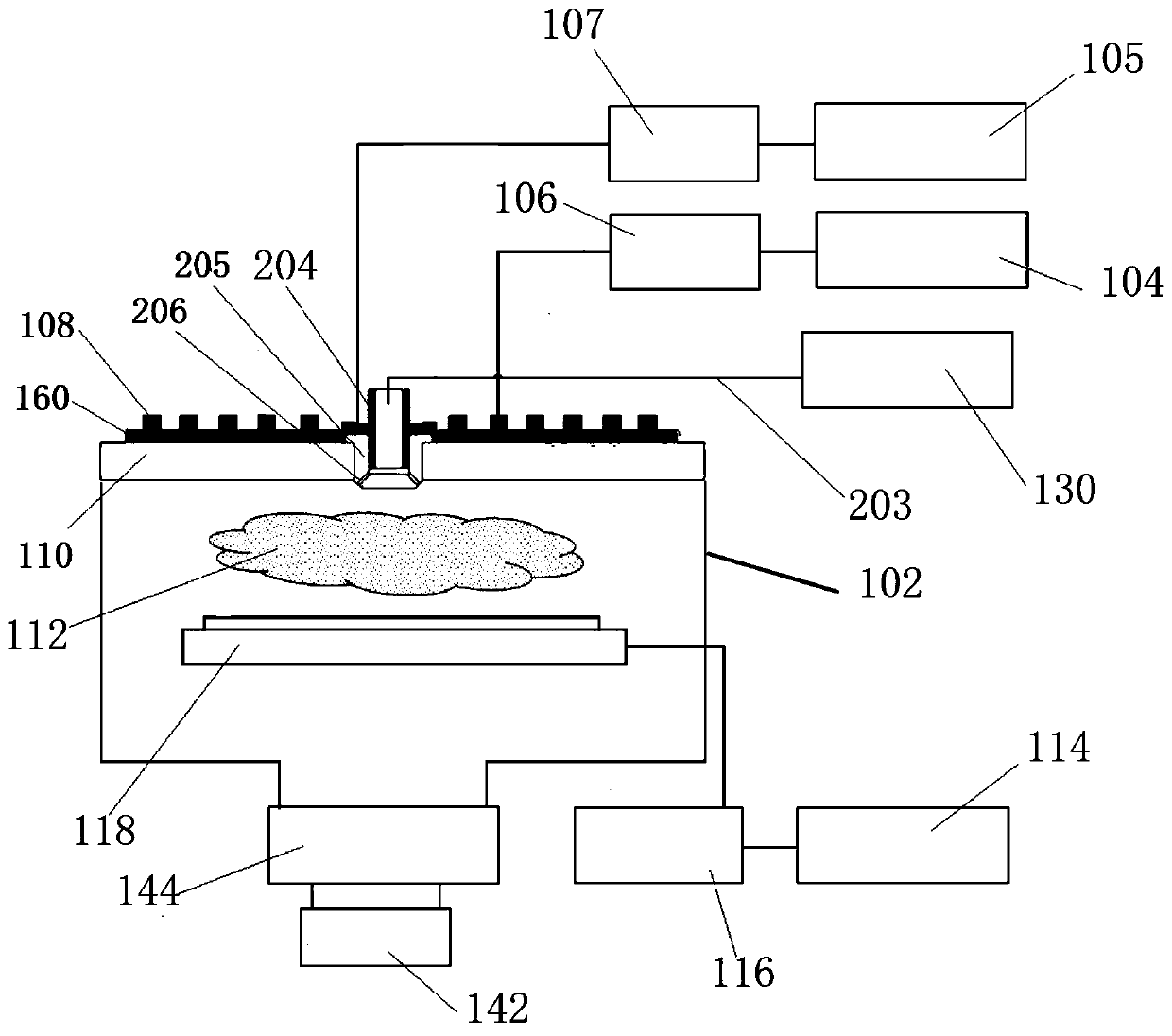

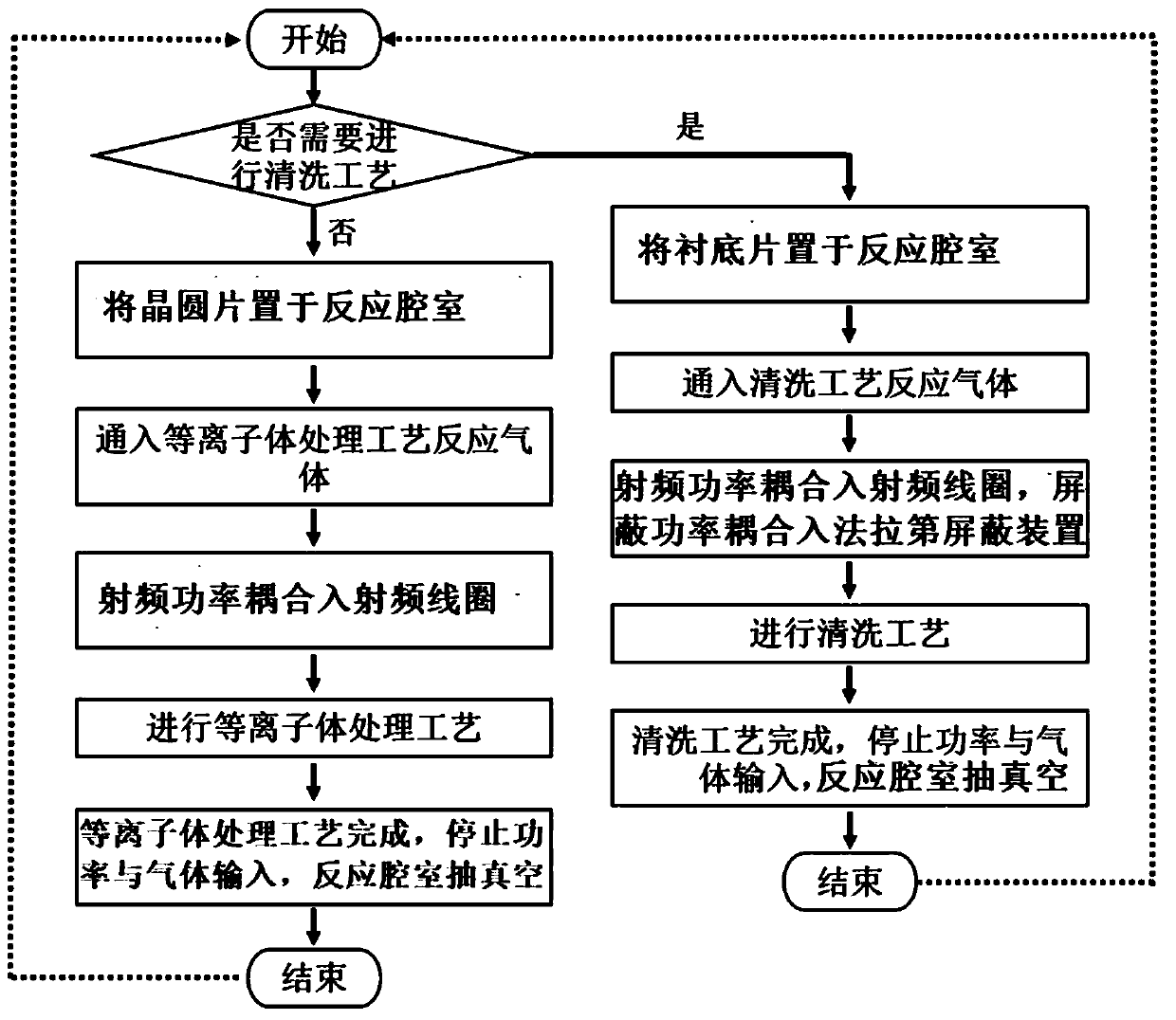

[0027] Embodiment 1, the air outlet port of the air intake nozzle 204 is connected to an extended air intake pipe 205 installed with insulating material; the extended air intake pipe 205 is provided with a number of first air intake holes 206; the extended air intake pipe 205 passes through The medium window 110 communicates with the reaction chamber 102 through the first inlet holes 206 ; the inner wall of the medium window 110 is located between the gas outlet port of the inlet nozzle 204 and the reaction chamber 102 . By extending the inlet pipe 205 , the gas outlet port of the inlet nozzle 204 can communicate with the reaction chamber 102 without protruding into the reaction chamber 102 . And the air outlet port of the air inlet nozzle 204 can be adjusted according to needs, and can be located between the inner wall and the outer wall of the medium window 110 , or can be located outside the outer wall of the medium window 110 . In addition, the extended air intake pipe 205...

Embodiment 2

[0029] Embodiment 2, the gas outlet port of the inlet nozzle 204 is embedded in the medium window 110, and the gas outlet port is located between the inner wall and the outer wall of the medium window 110; Several second air intake holes. Because the second embodiment needs to open holes on the dielectric window 110 , the processing cost is higher than that of the first embodiment, and it is not easy to maintain when the second air inlet is clogged or other faults occur.

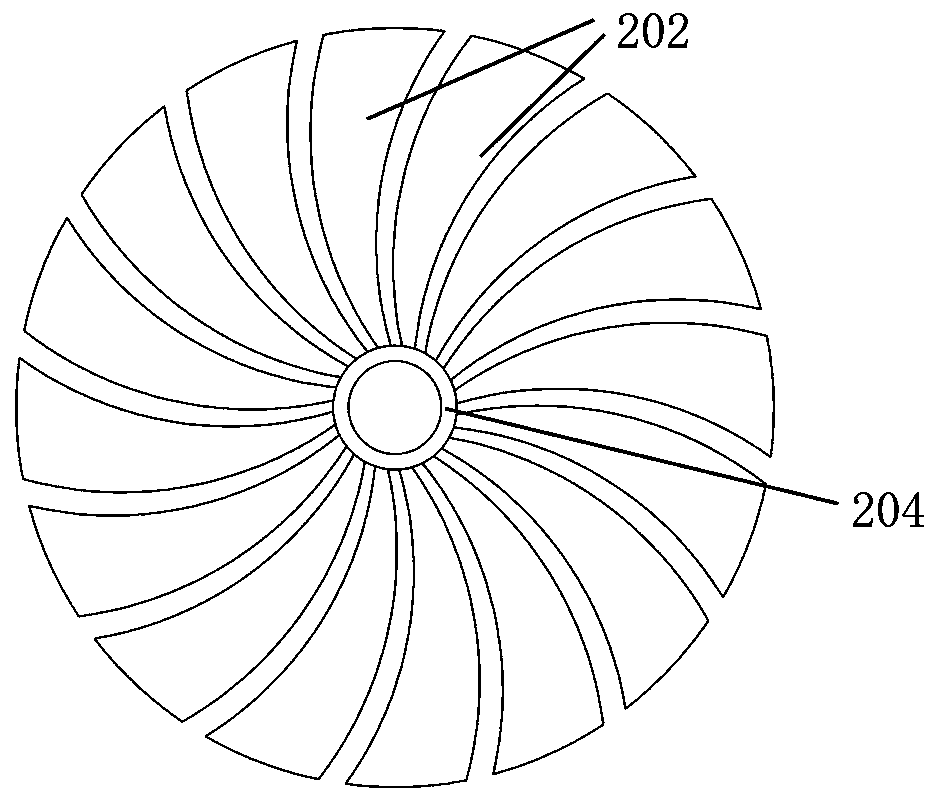

[0030] The Faraday shielding device 160 of the present invention includes a plurality of center-symmetric petal-shaped components 202 arranged at intervals; one end of the plurality of petal-shaped components 202 close to the center of symmetry is provided with a through hole. The air intake nozzle 204 passes through the through hole, and the inner circle of the through hole is electrically connected to the air intake nozzle 204. Specifically, the connection mode between the inner circle of the through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com