Coil panel of induction cooker and winding method thereof

A technology for coil coils and induction cookers, which is applied to coil devices, household stoves/stoves, electric heating fuels, etc. It can solve the problems of heating blind areas, susceptibility to uneven heating, large area, etc., achieve thin wire coil thickness, reduce heating blind areas, Effect of increasing coil winding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

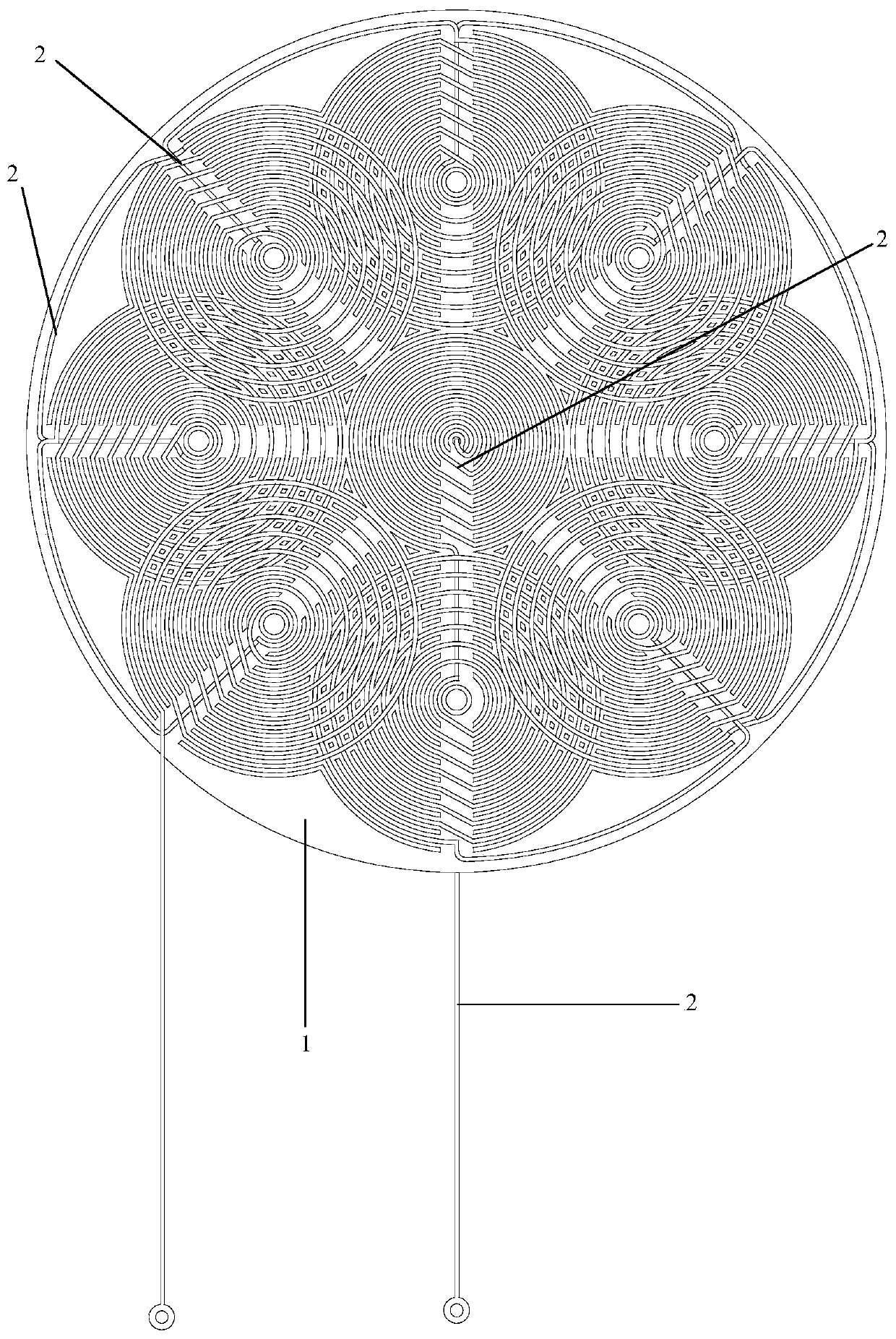

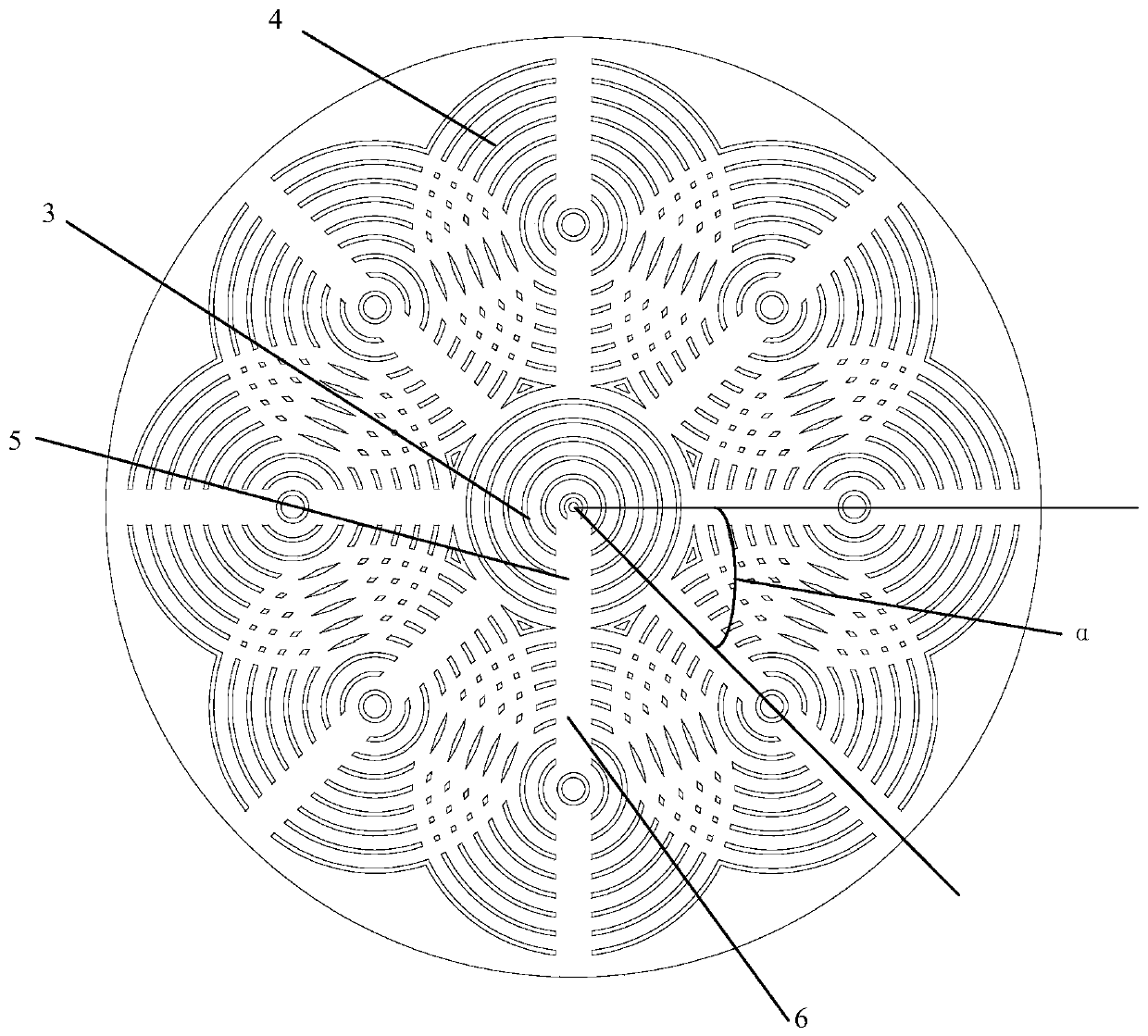

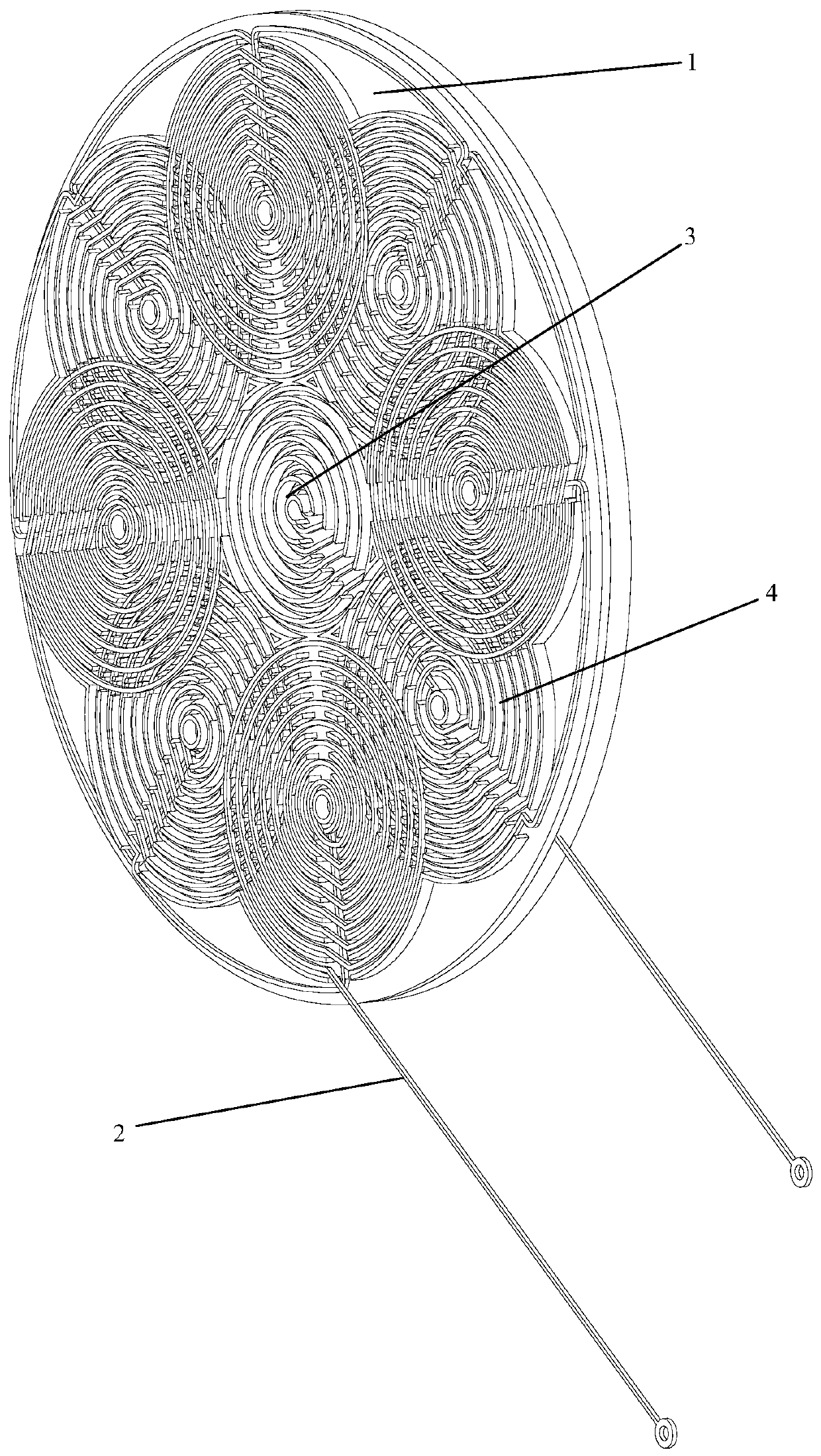

[0031] In order to solve the above technical problems, the present invention is implemented in the following manner, as shown in the figure: an induction cooker coil plate, which includes a coil base 1 and an enameled wire 2; the coil base 1 is provided with a wire groove for coiling the enameled wire 2 The wire groove includes a central wire groove 3 and a plurality of surrounding wire grooves 4 evenly arranged around the center wire groove 3; the center wire groove 3 includes a plurality of circular wire grooves centered on the center of the wire reel base; the surrounding wire groove 4 includes multiple There are annular wire grooves with a common center, and adjacent surrounding wire grooves 4 overlap each other.

[0032] Further, the center of the circle around the slot 4 is set on a circle with the center of the center slot 3 as the center.

[0033] Further, the radius of the circle around the center of the wire groove 4 is greater than the radius of the centerline groove 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com