High-stability ultralow-mercury catalyst, and preparation method and application thereof

A high-stability, ultra-low-mercury technology, applied in the direction of hydrogen halide addition preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of cumbersome preparation methods and difficult industrial application, so as to improve catalytic activity, Improved dispersion and enhanced thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

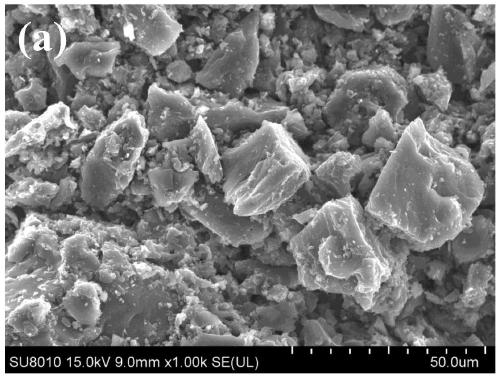

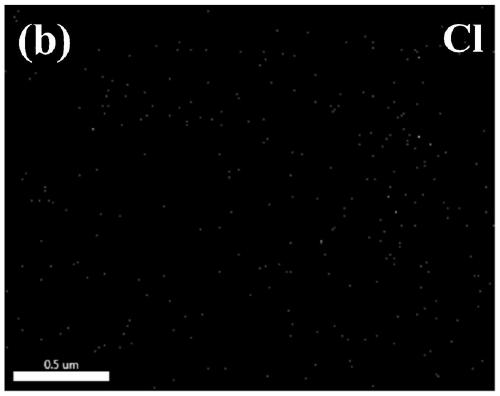

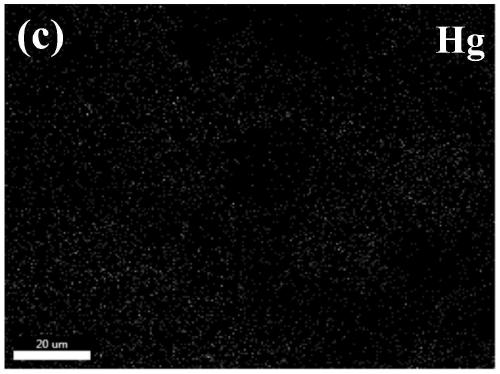

[0039] (1) Weigh 2kg of coal-based carbon powder, 0.2kg of barium nitrate and 0.2kg of copper nitrate to obtain a mixture, then weigh 0.5kg of sucralose and dissolve it in 1.6L of deionized water. After the sucralose is completely dissolved, gradually Add it to the mixture of carbon powder and metal nitrate, stir and knead it, and then place it at room temperature for 10 hours.

[0040] (2) Send the sample obtained in step (1) into an extruder to press and extrude to form a columnar carbon with a diameter of 1.5mm, place it at room temperature for 10h, and then dry it at 110°C for 8h to remove excess moisture.

[0041] (3) Put the sample obtained in step (2) into a rotary furnace, and under nitrogen, raise the temperature to 800°C at a heating rate of 5°C / min and keep it warm for 5 hours for deep carbonization treatment, and naturally cool to room temperature to obtain chlorine-doped Miscellaneous defective activated carbon.

[0042](4) take by weighing 1kg step (3) to obtai...

Embodiment 2

[0044] (1) Weigh 2kg of wood charcoal powder, 0.2kg of barium nitrate and 0.2kg of copper nitrate and mix evenly to obtain a mixture, then weigh 0.5kg of sucralose and dissolve it in 1.6L of deionized water. After the sucralose is completely dissolved, gradually add Stir and knead into the mixture of charcoal powder and metal nitrate, and then place it at room temperature for 10 hours.

[0045] (2) Put the sample obtained in step (1) into an extruder and extrude it to form a columnar carbon with a diameter of 1.5 mm. Place it at room temperature for 10 hours, and then dry it at 110°C for 8 hours to remove excess water. .

[0046] (3) The sample obtained in step (2) was sent into the rotary furnace again, and under the condition of nitrogen, the temperature was raised to 800° C. at a heating rate of 5° C. / min and kept for 5 hours for deep carbonization treatment. Naturally cooled to room temperature, chlorine-doped defective activated carbon was obtained.

[0047] (4) take by...

Embodiment 3

[0049] (1) Weigh 2kg of coal-based carbon powder, 0.2kg of barium nitrate, 0.2kg of copper nitrate and 0.5kg of sucralose and mix evenly, measure 1.6L of deionized water, and gradually add to the carbon powder, metal nitrate and sucralose After stirring and kneading the mixture, it was left at room temperature for 10 h.

[0050] (2) Put the sample obtained in step (1) into an extruder and extrude it to form a columnar carbon with a diameter of 1.5 mm. Place it at room temperature for 10 hours, and then dry it at 110°C for 8 hours to remove excess water. .

[0051] (3) Put the sample obtained in step (2) into a rotary furnace, and under nitrogen, raise the temperature to 800°C at a heating rate of 5°C / min and keep it warm for 5 hours for deep carbonization treatment, and naturally cool to room temperature to obtain chlorine-doped Miscellaneous defective activated carbon.

[0052] (4) take by weighing 1kg step (3) to obtain the defect activated carbon doped with chlorine and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com