Arrangement method for double circulation process of interior wallboard member production line

A layout method and production line technology, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of reducing production efficiency and component quality, pipeline discontinuity, unbalanced process waiting time, etc., to achieve production efficiency Improve and avoid the effect of pipeline freeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

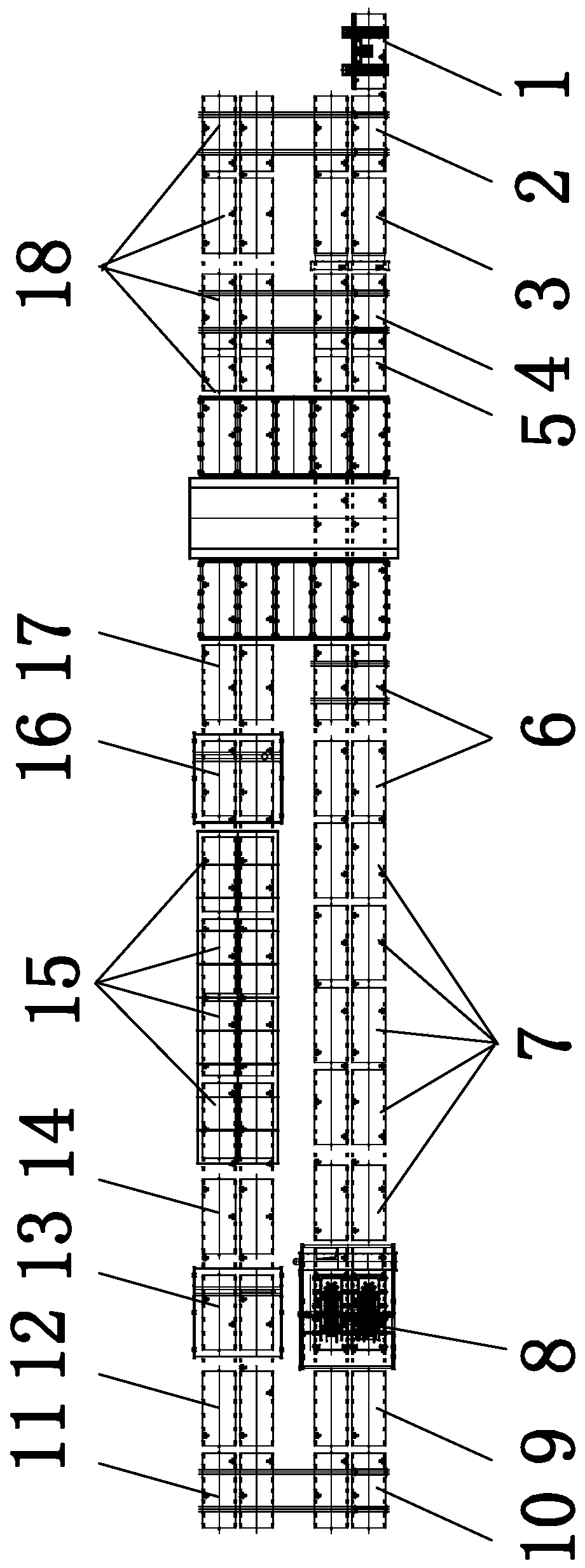

[0042] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0043] attached Figure 2-5 It can be seen that a double-cycle process layout method for an interior wall panel production line,

[0044] The pipeline includes the following steps:

[0045] mold cleaning;

[0046] Release agent spraying;

[0047] side molding line;

[0048] side formwork installation;

[0049] Rebar installation;

[0050] Embedded installation;

[0051] Pouring and vibrating;

[0052] scrape;

[0053] static, pre-curing;

[0054] Surface calendering treatment;

[0055] steam curing;

[0056] demoulding;

[0057] Rough surface treatment;

[0058] Storage;

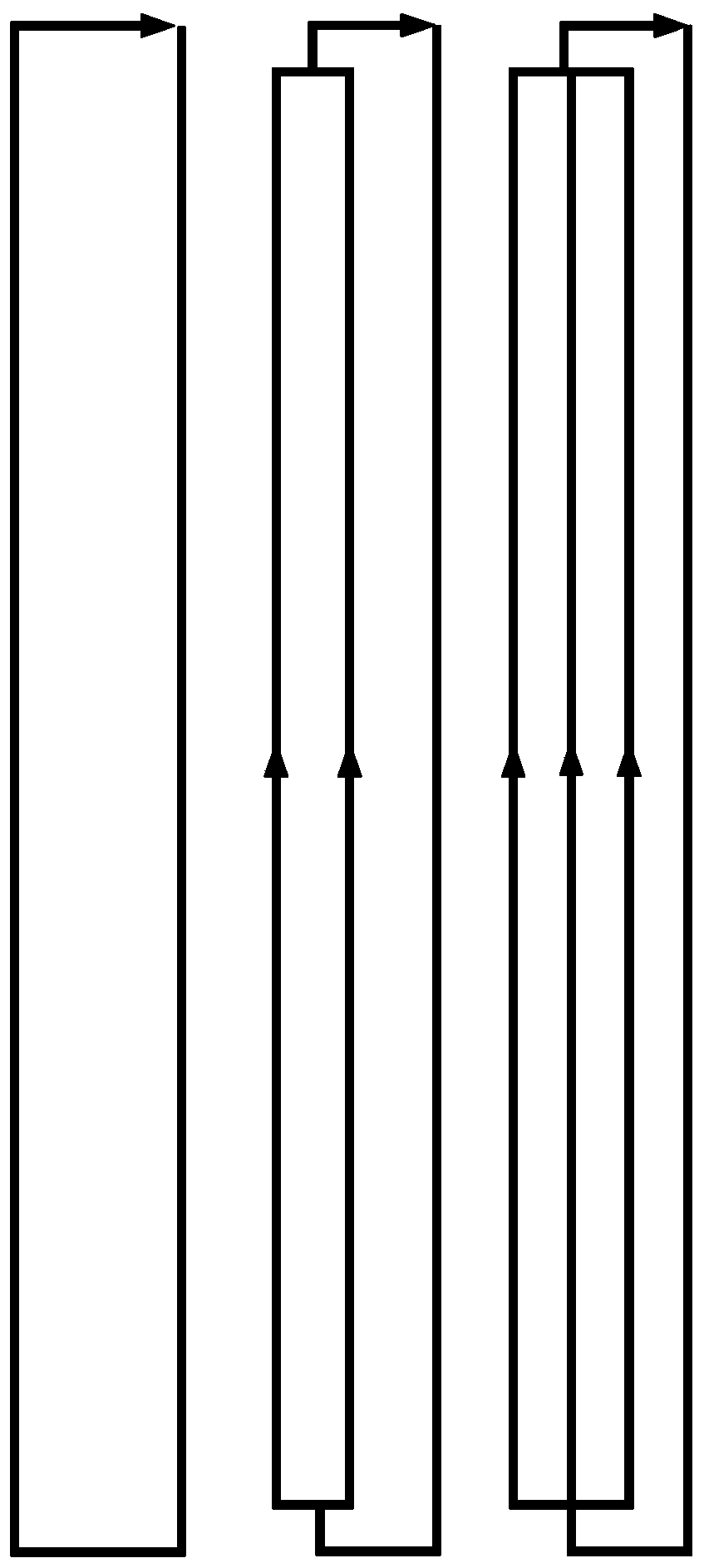

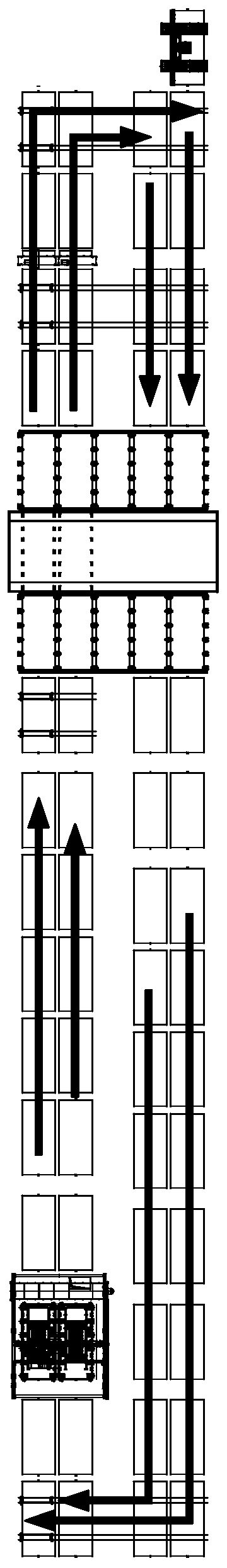

[0059] The assembly line adopts two independent circulation lines, the inner circulation and the outer circulation.

[0060] The dual-circulation process layout method of the interior wall panel component production line of the present invention avoids the line jams and staff idle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com