Portable assembly type rail car, spraying operation system and method

An operating system and assembly technology, applied in coating, transporting passenger cars, spraying devices, etc., can solve the problem that the automatic spraying operation is difficult to start, the special spraying operation rail car has not yet appeared, and the equipment, personnel and materials are difficult to move as a whole at the same time, etc. problem, to achieve the effect of quick and efficient spraying operation, reduced labor intensity of disassembly and assembly, and tight docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

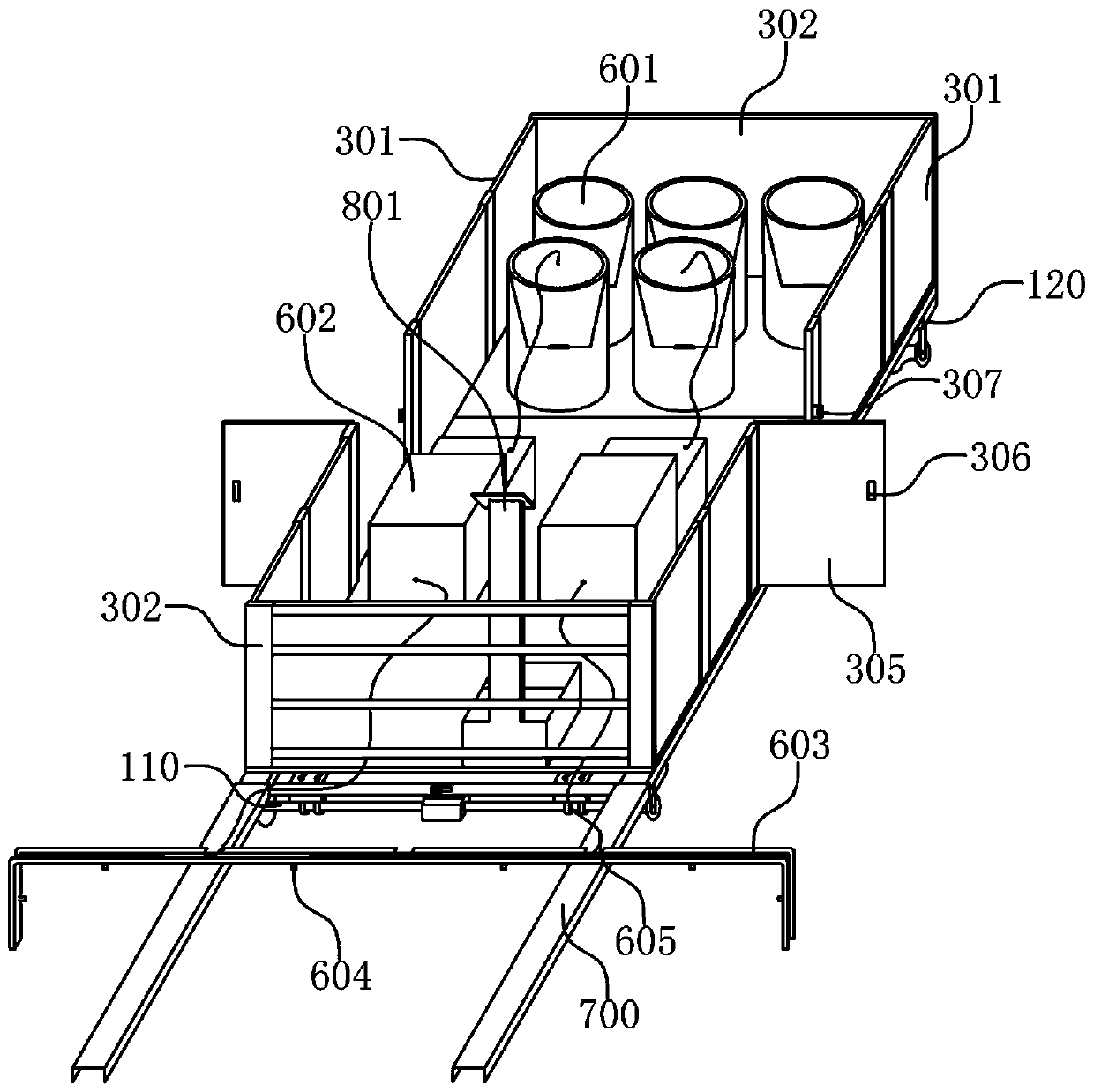

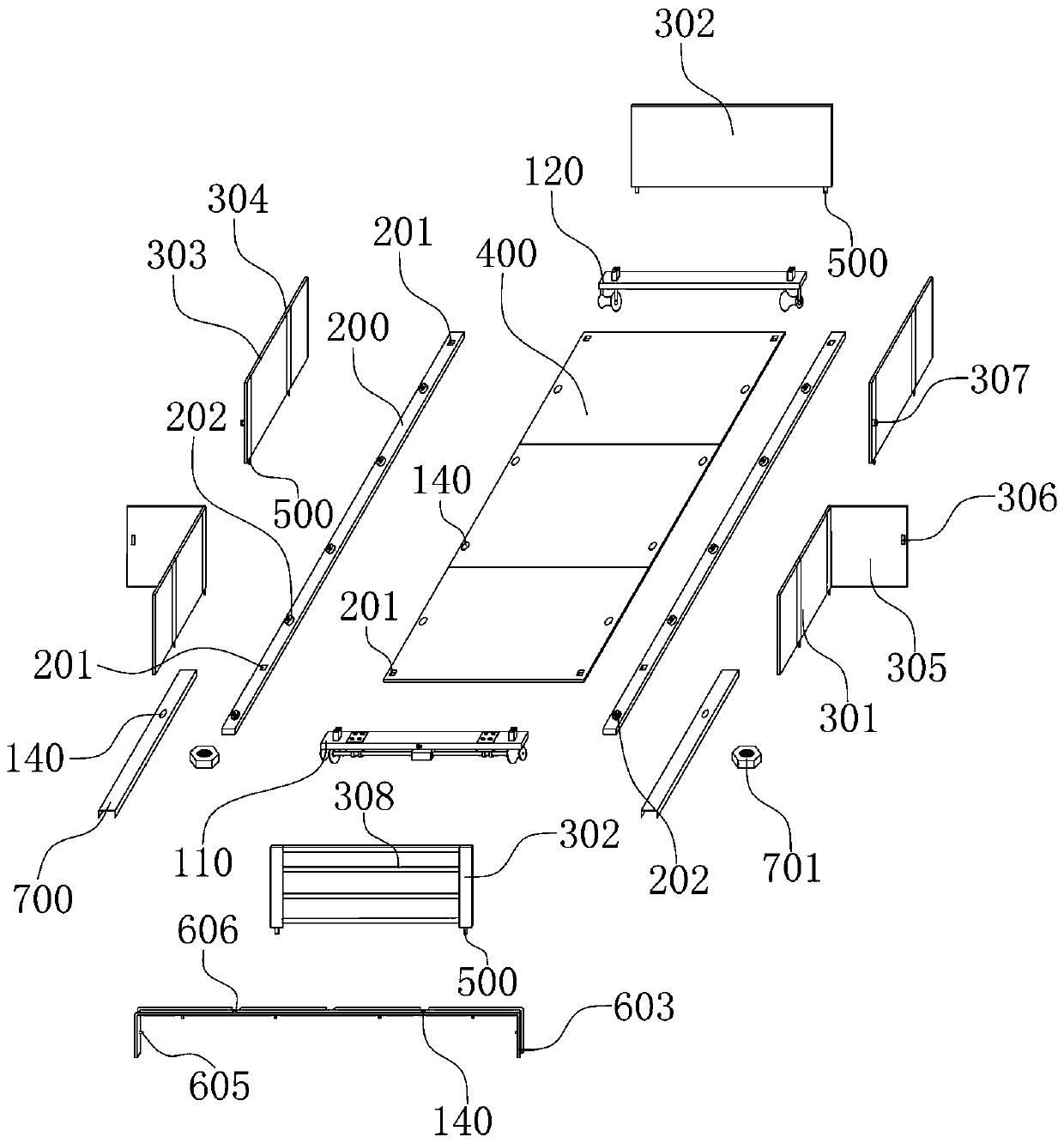

[0039] see Figure 1-Figure 5 , a portable assembled rail vehicle of the present invention, comprising a front axle 110 and a rear axle 120 correspondingly arranged front and rear, a load longitudinal beam 200, a side box body and a load floor 400, and the load longitudinal beam 200 is detachably assembled and arranged on the front axle 110 and the rear axle 120, and assembled with the front axle 110 and the rear axle 120 to form a walking chassis; the side boxes are detachably assembled on each side of the walking chassis; on the walking chassis.

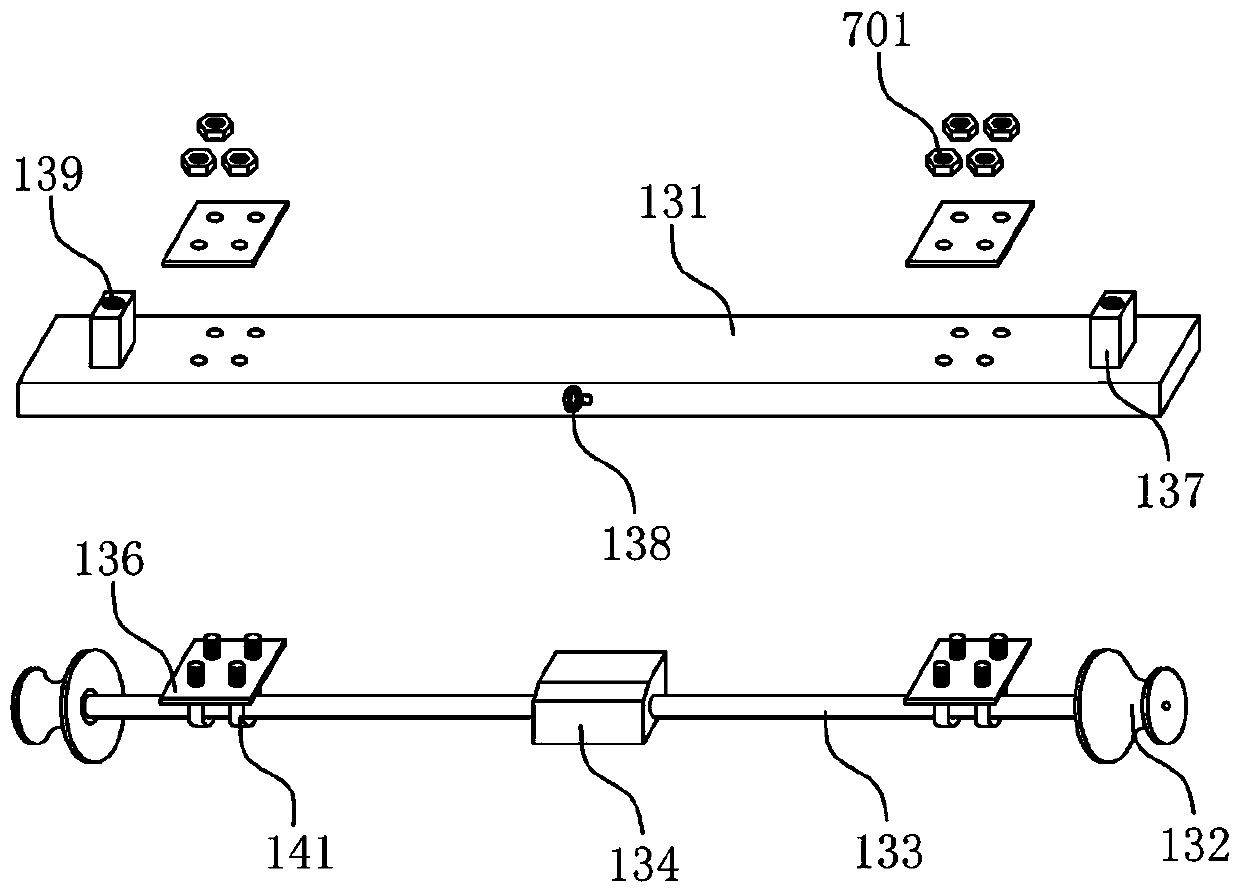

[0040] The front axle 110 and the rear axle 120 both include a load-bearing beam 131 and a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com