Detachable cargo hold connecting wing double-fuselage logistics unmanned aerial vehicle

A dual-fuselage, dismantling technology, applied in the direction of equipment, fuselage, full-wing aircraft for loading and unloading goods, etc., can solve the limitations of the popularity of logistics drones, low economy and loading efficiency, and drone payloads. Small and other problems, to achieve the effect of flexible load loading, improve cargo handling efficiency, improve aerodynamic characteristics and structural characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

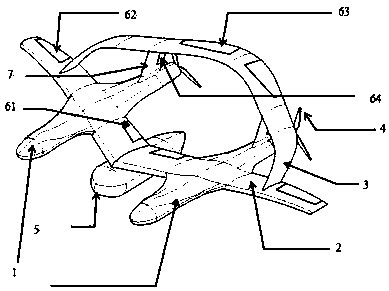

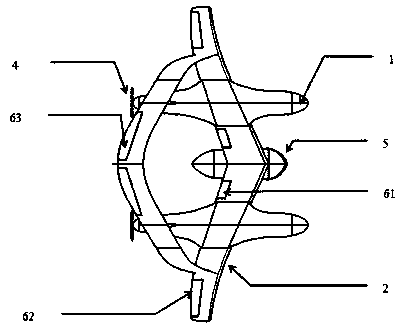

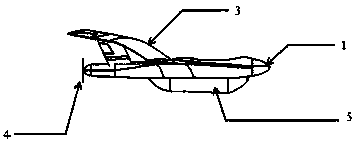

[0025] A detachable logistics UAV with connecting wings and double fuselages of the present invention, the detachable logistics UAV with connecting wings and double fuselages of the cargo compartment includes a wing-body fusion double fuselage 1, a lower main wing 2, Upper auxiliary wing 3, propulsion device 4, modular detachable cargo hold 5, flight control system 6 and vertical tail 7.

[0026] The wing-body fused twin fuselage 1 and the lower main wing 2 adopt a smooth transition on a curved surface, and the lower main wing 2 and the upper auxiliary wing form a connecting wing structure. The wing-body fused twin fuselage 1 is located at the position where the lower main wing 2 is 0.2 times half-span from the wing root.

[0027] The lower main wing 2 adopts a low-speed airfoil with a sweep angle of 10 degrees and a dihedral angle of 0 to 3 degrees to improve flight stability. The upper auxiliary wing 3 is connected to the wing tip position of the lower main wing 2, and is 0...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is:

[0035] The wing-body fused twin fuselage 1 is located at the position where the lower main wing 2 is 0.3 times half-span from the wing root;

[0036] The lower main wing 2 adopts a low-speed airfoil with a sweep angle of 15 degrees and a dihedral angle of 1 degree;

[0037] Described upper auxiliary wing 3 is connected to the wingtip position of lower main wing 2, and is 0.15 times of half spread length from wing tip, forms the connecting wing structure, and described upper auxiliary wing 3 is low-speed airfoil, and the sweep angle is 25 degree.

[0038] The wing-body fused twin fuselage 1, the lower main wing 2 and the upper auxiliary wing 3 are made of aluminum-magnesium alloy and composite materials.

Embodiment 3

[0040] The wing-body fused twin fuselage 1 is located at the position where the lower main wing 2 is 0.4 times half-span from the wing root;

[0041] The lower main wing 2 adopts a laminar airfoil with a sweep angle of 20 degrees and a dihedral angle of 1 degree;

[0042] The upper auxiliary wing 3 is connected to the wing tip position of the lower main wing 2, and is 0.25 times half-span length from the wing tip to form a connecting wing structure. The upper auxiliary wing 3 is a laminar flow airfoil with a forward sweep angle is 35 degrees.

[0043] The wing-body fused twin fuselage 1, the lower main wing 2 and the upper auxiliary wing 3 are made of aluminum-magnesium alloy and carbon fiber materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com