Method and system for controlling industrial crane capable of self-adapting speed planning

A speed planning and control system technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the hidden dangers of ground workers, affect the handling efficiency and other problems, achieve the effect of suppressing the swing of the load and meeting the position accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

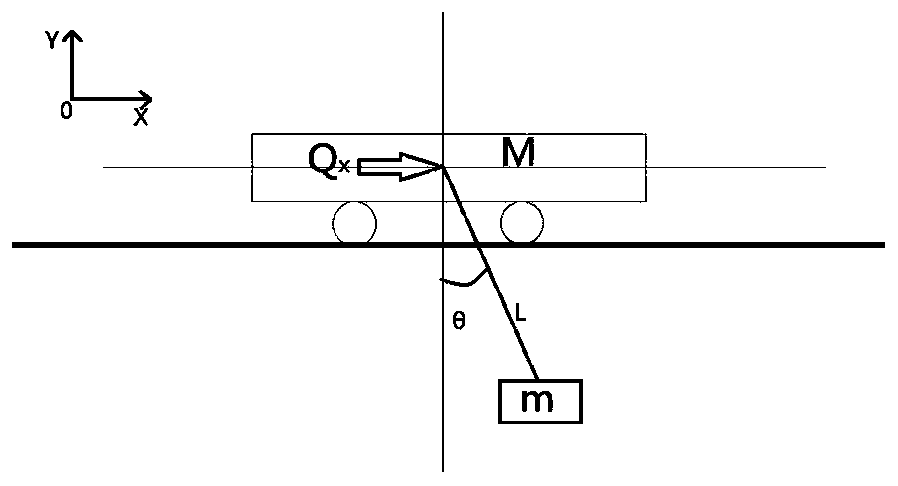

[0024] The trolley of the bridge crane is a complex underactuated system, and the number of independent control variables of the system is less than the number of degrees of freedom of the system. After simplified processing, it is shown as figure 1 Shown: The trolley of the bridge crane with mass M moves along the x-axis under the action of force F, and a heavy object with mass m is hung on the trolley of the bridge crane through a wire rope to perform an approximate simple pendulum motion.

[0025] The displacement of the bridge crane trolley and the weight in the plane coordinate system:

[0026]

[0027] Where L is the total energy of the system, and the bridge crane trolley is modeled by the Euler-Lagrange method, and the differential equation of motion of the system is obtained:

[0028]

[0029] where Q x is the force applied to the brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com