A kind of reactive polyurethane hot melt adhesive and its preparation method and application

A polyurethane hot-melt adhesive, reactive technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of limited application and promotion occasions, and achieve high initial strength and high elongation. , the effect of good heat resistance

Active Publication Date: 2021-09-03

格丽泰新材料科技(苏州)有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since UV curing can only be used on transparent substrates and other bonding surfaces, such as transparent glass and other materials, the application and promotion occasions are very limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0055] The reactive polyurethane hot melt adhesive of Example 1 is measured according to GB / T 531. The Shore D hardness is about 45, the tensile strength is about 15 MPa according to GB / T 528, and the elongation at break is about 100% according to GB / T 528. The construction temperature 120~160℃, the long-term temperature resistance range after curing is -40~110℃, and the short-term temperature resistance range after curing is 130~140℃.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Login to View More

Abstract

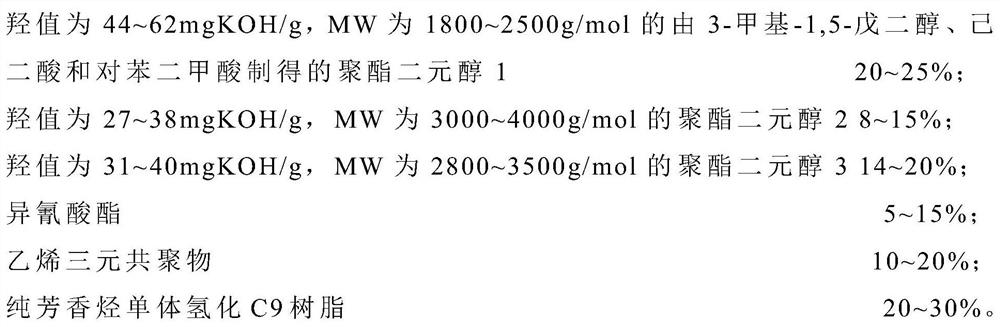

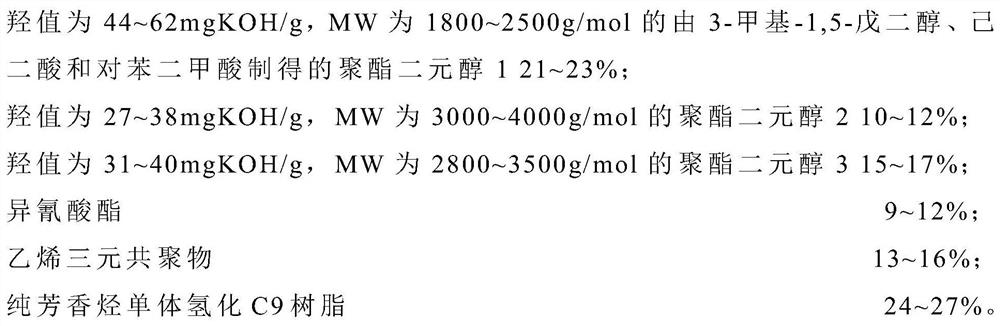

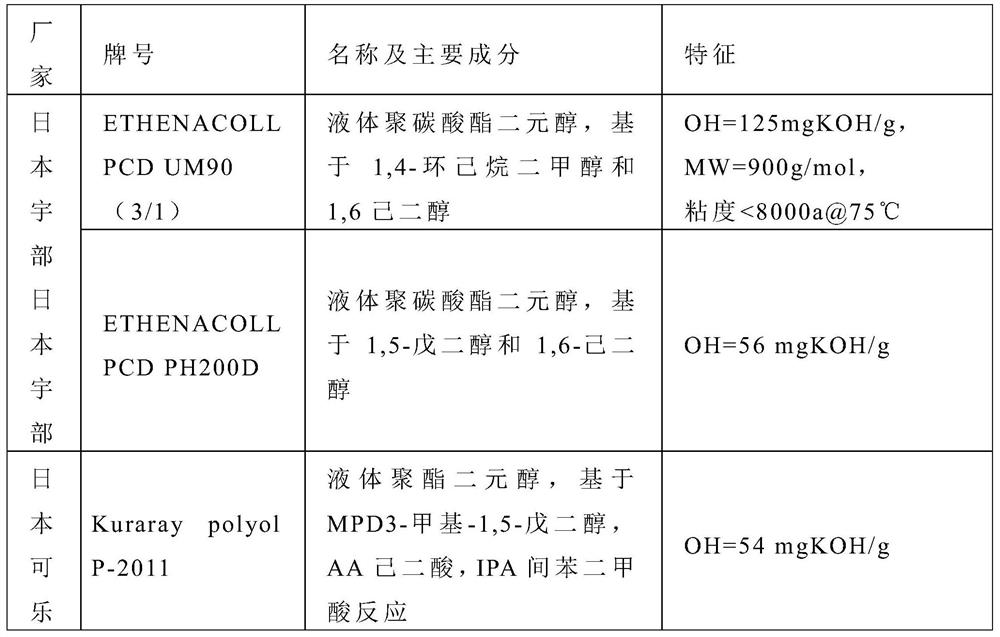

The invention relates to a reactive polyurethane hot melt adhesive, which comprises the following raw material components in terms of weight percentage: 3-methyl-1,5 ‑Pentylene glycol, adipic acid and terephthalic acid polyester diol1 20~25%; hydroxyl value 27~38 mgKOH / g, MW 3000~4000g / mol polyester diol 2 8~15%; polyester diol with hydroxyl value 31~40 mgKOH / g, MW 2800~3500g / mol 3 14~20%; isocyanate 5~15%; ethylene terpolymer 10~20% ; Pure aromatic hydrocarbon monomer hydrogenated C9 resin 20~30%. The invention has high initial strength, high elongation, good elasticity and toughness, and good heat resistance.

Description

technical field [0001] The invention belongs to the technical field of chemical adhesives, and in particular relates to a reactive polyurethane hot melt adhesive and its preparation method and application. Background technique [0002] Moisture-curing polyurethane hot-melt adhesive, referred to as PUR, is solid at room temperature and does not contain solvent plasticizers. When in use, it is heated to make it liquid and immediately applied to the surface of the adherend, and then attached to another adherend. When the adhesive is cooled and solidified, the isocyanate reacts with the moisture on the surface of the adherend or the moisture in the air to extend the chain into a polymer compound, thereby producing an adhesive force. Compared with other hot-melt adhesives, reactive polyurethane hot-melt adhesives (PU-RHMAs) have the following advantages: low operating temperature, high thermal stability (moisture cross-linking and curing), and good adhesion on different substrate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J175/06C09J123/08C09J157/02C08G18/42

CPCC08G18/4202C08L2205/03C09J175/06C08L23/0853C08L57/02

Inventor 徐亚芳

Owner 格丽泰新材料科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com