Fabricated steel-bamboo combined semi-rigid energy dissipation joint frame

A semi-rigid, prefabricated technology, applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve the problems of dissipating seismic energy, insignificant ductility and energy dissipation, and damage to components and nodes, etc., to achieve The effects of improving rotational stiffness, low cost, and simplified structural configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

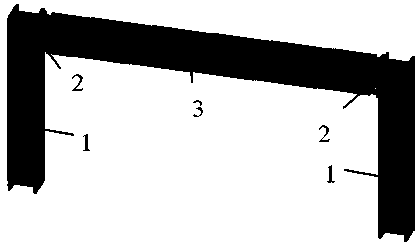

[0019] Such as figure 1 As shown, a prefabricated steel-bamboo combined semi-rigid energy-dissipating node frame, its structure includes steel columns 1, semi-rigid energy-dissipating nodes 2, and bamboo beams 3; wherein the bamboo beams 3 are set on two vertical and parallel Between the tops of the steel columns 1, the two ends of the bamboo beams 3 are respectively connected to the steel columns 1 through a semi-rigid energy dissipation node 2, forming the foundation of the semi-rigid energy dissipation node frame.

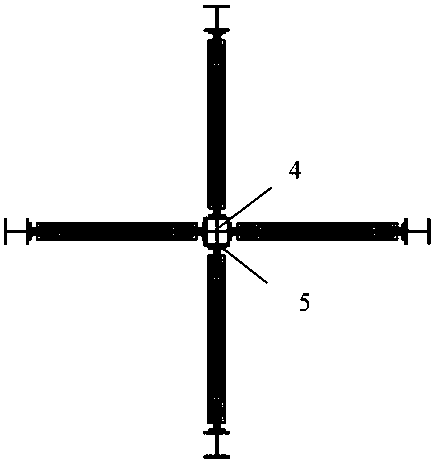

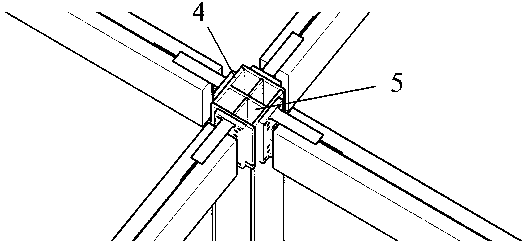

[0020] Such as figure 2 As shown, the assembled steel-bamboo composite semi-rigid energy dissipation node frame can also be composed of a central steel column connected to four steel columns 1 at the same time, wherein the center steel column and the remaining four steel columns 1 They are all connected by a bamboo beam 3, and a semi-rigid energy dissipation node 2 is provided at both ends of each bamboo beam 3, and the angle between two adjacent steel columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com