Horizontal well drilling and drilling pressure compensating device

A compensation device, horizontal well technology, applied in drilling equipment, directional drilling, drill pipe, etc., can solve problems such as large bottom-hole WOB floating, inability to accurately control bottom-hole WOB, and high friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

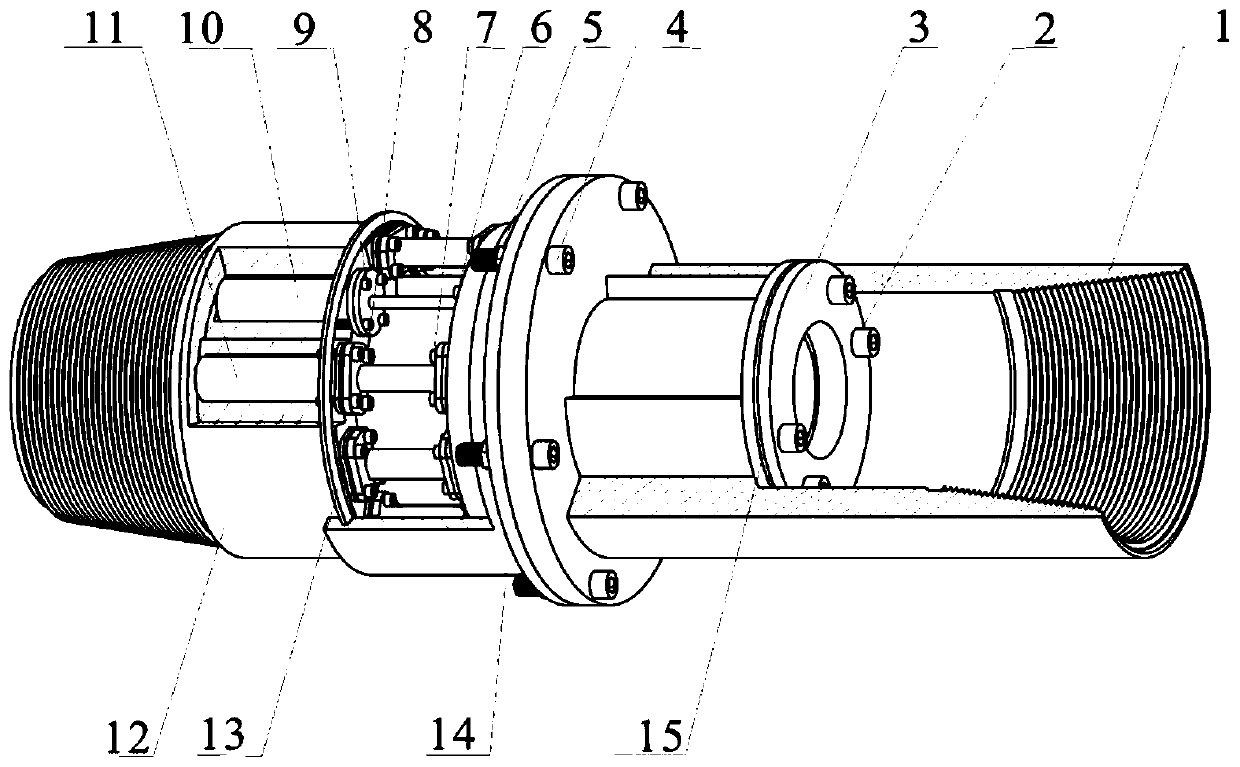

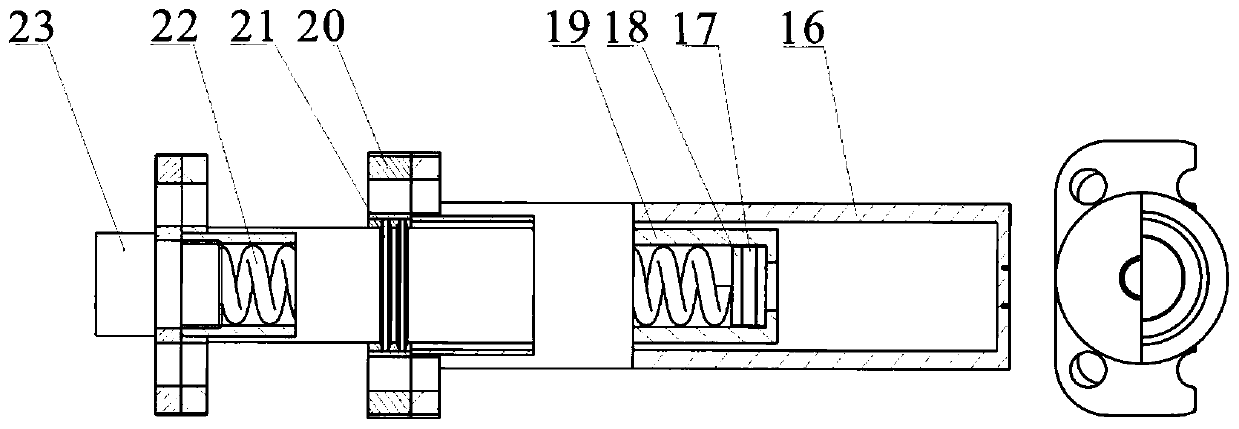

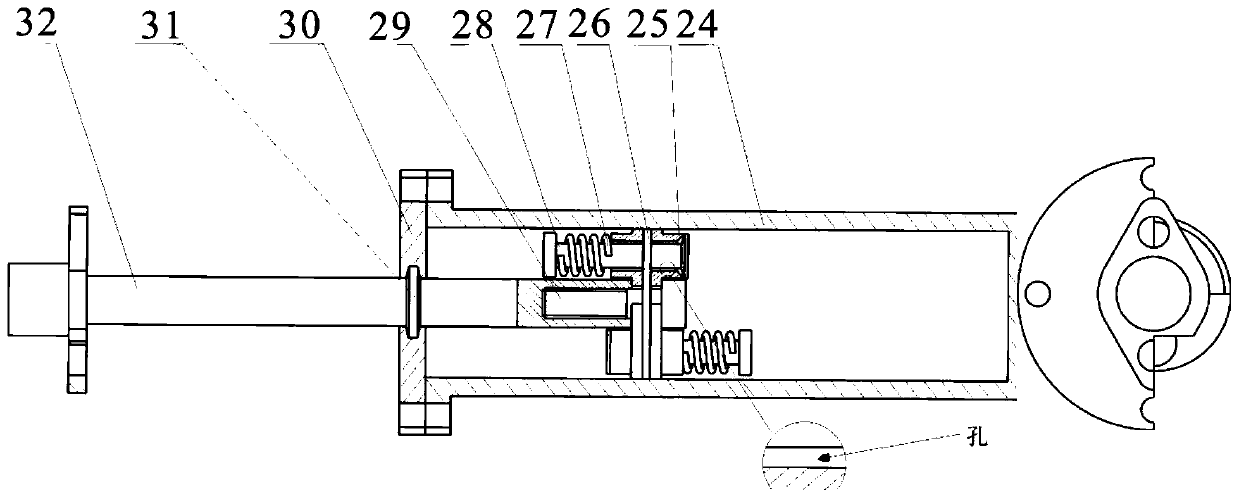

[0024] refer to figure 1 , The drilling pressure compensation device for horizontal well drilling, including torque transmission system, tension transmission system, drilling pressure compensation system, shock absorption system, sealing system, etc. constitute an organic whole.

[0025] The torque transmission system is composed of a lower joint body 12 and an upper joint body 1 . The neck shape of the upper joint main body 1 is similar to the internal spline (such as Figure 4 shown), the neck shape of the lower joint body 12 is similar to an external spline (such as Figure 5 As shown), the neck of the lower joint body 12 passes through the center of the upper joint body 1 and cooperates with the neck of the upper joint body 1, and the neck of the lower joint body 12 is longer than the neck of the upper joint body 1. After the upper joint main body 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com