A hydraulic double-layer pipe double-gradient downhole blowout preventer valve

A blowout preventer, double-layer pipe technology, applied in wellbore/well valve device, wellbore/well components, construction, etc., can solve problems such as manual opening or replacement of parts, and achieve the effect of reliable plugging performance

Active Publication Date: 2022-05-31

SOUTHWEST PETROLEUM UNIV +1

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It solves the problem of manually opening or replacing parts after the traditional downhole blowout preventer is closed, and achieves the purpose of reusability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

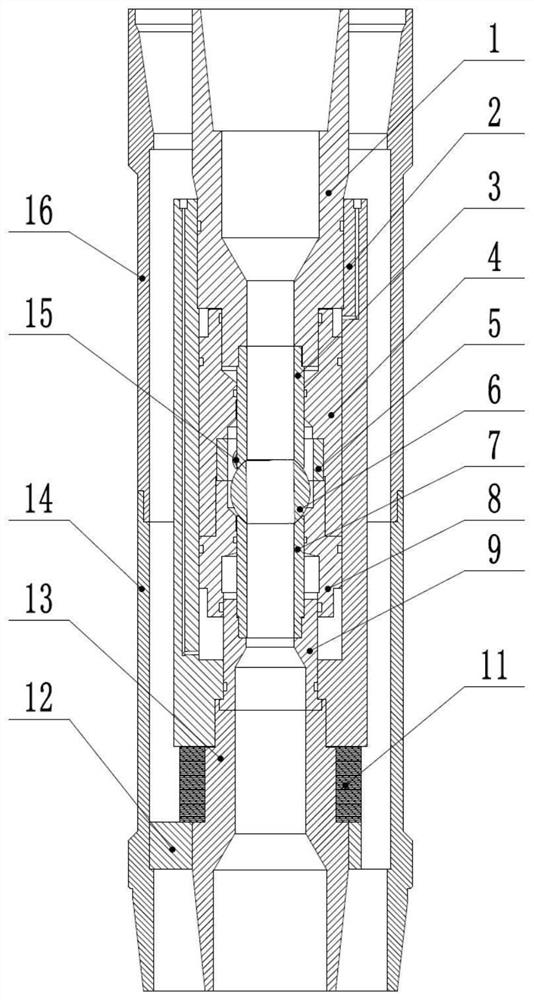

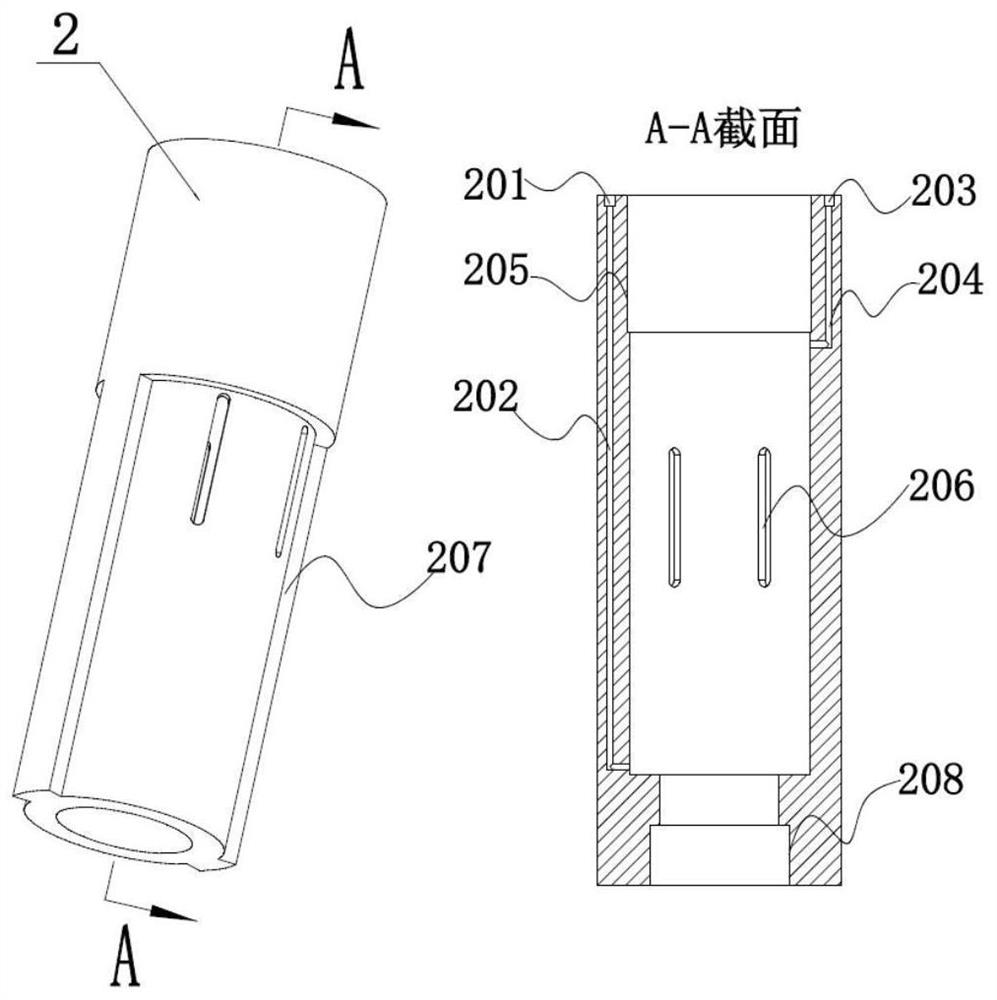

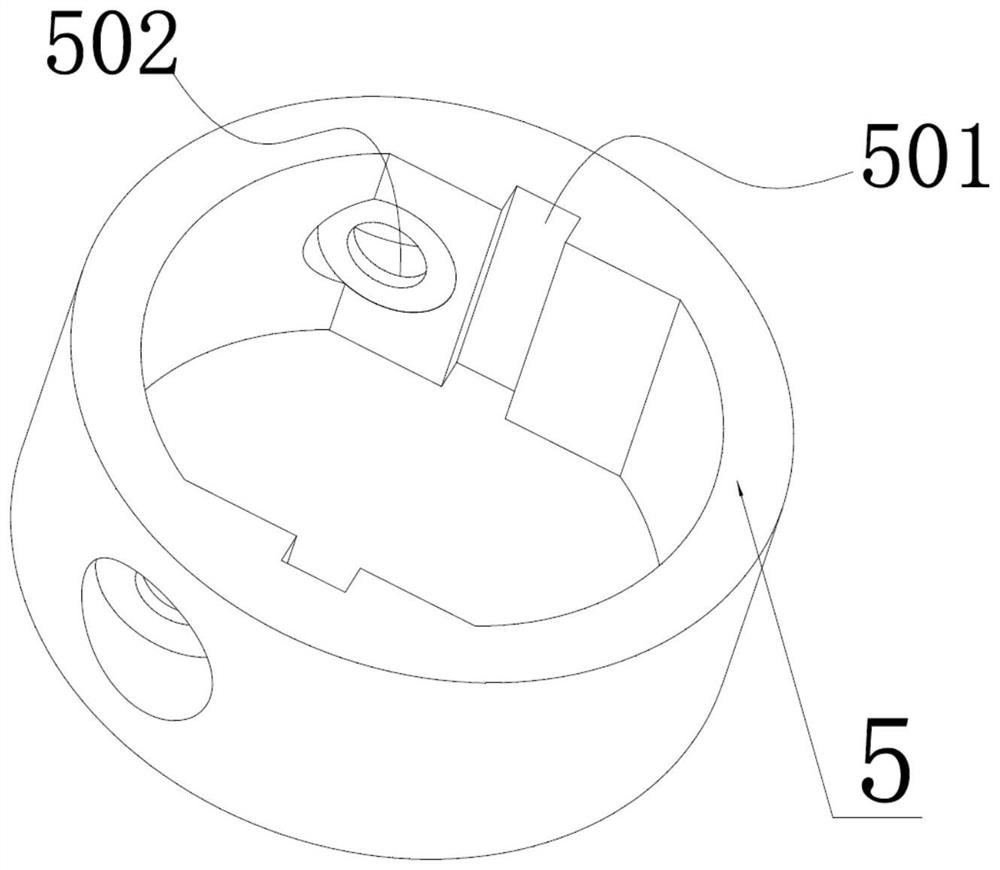

The invention relates to a hydraulic double-tube double-gradient downhole blowout preventer valve. The downhole blowout preventer valve is mainly composed of an upper joint and a lower joint, an intermediate casing installed between the upper and lower joints, and an intermediate casing installed on the middle casing. The extrusion plate, the upper valve seat, the lower valve seat, the ball valve driving device installed between the upper and lower valve seats, the overflow pipe installed on the ball valve driving device, and the rubber tube installed on the lower joint. The double-layer pipe inner pipe plugging structure is mainly composed of upper and lower valve seats, ball valves, and ball valve driving devices. The ball valve driving device is composed of a driving sliding sleeve and an eccentric pin. The beneficial effect of the present invention is that it can realize the controllable and simultaneous plugging of the annulus channel of the inner and outer tubes of the double-layer pipe and the channel of the inner tube when a kick or blowout occurs at the bottom of the well; the plugging effect is stable, and the plugging effect is not affected by the well. Bottom pressure fluctuations can ensure the safety of double-layer pipe dual-gradient pressure-controlled drilling; after the well killing is completed and well kick and blowout are under control, the blowout preventer valve can be reopened to ensure normal drilling.

Description

A hydraulic double-tube double-gradient downhole blowout preventer technical field The present invention relates to the technical field of double-layer pipe double-gradient managed pressure drilling, be specifically related to a kind of hydraulic type double-layer pipe double ladder Downhole blowout preventer. Background technique [0002] Marine gas hydrate is regarded as the main alternative energy in the future because of its high energy density and huge reserves. It is a hot spot in the world's energy development. There are abundant oil and gas and natural gas hydrate resources in the South my country Sea, most of which are It is stored in the deep water sea area, and drilling in this sea area needs to face the narrow pressure window of deep water drilling operation, leakage-prone production layers, and seabed. The problems of safe drilling of loose surface layers and low leakage pressure of shallow hydrate layers in the seabed are difficult. It is expected to so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21B34/08

CPCE21B34/08E21B2200/04

Inventor 唐洋赵鹏王国荣李炎军李绪深李泽良王远赵金海熊浩宇徐一龙倪申童刘和兴马传华

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com