A degassable anchor injection device for ordinary anchor rods and its application method

A common anchor and anchor injection technology, applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of increasing construction difficulty and work intensity, gas cannot be effectively discharged, and it is difficult to block again in time, reaching the workload Small size, simple structure, and the effect of preventing false grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

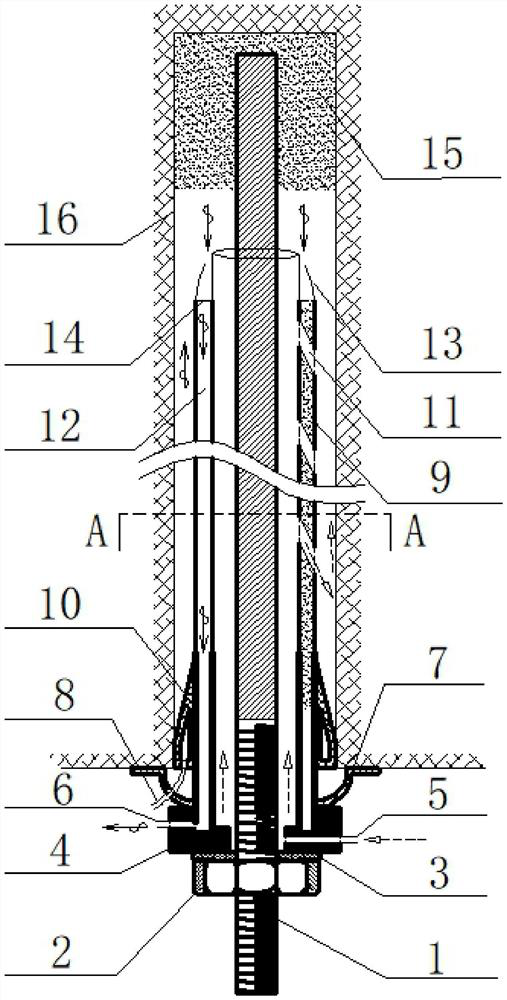

[0032] Below in conjunction with accompanying drawing, the present invention will be further described.

[0033] The working principle of the present invention:

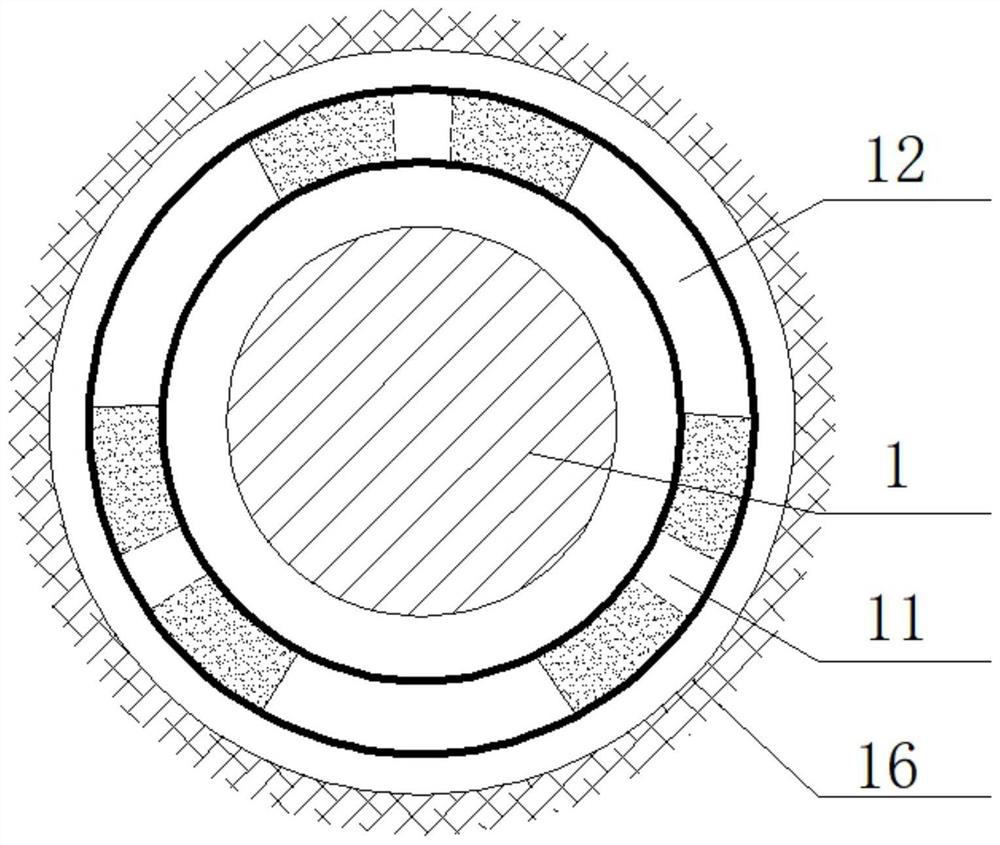

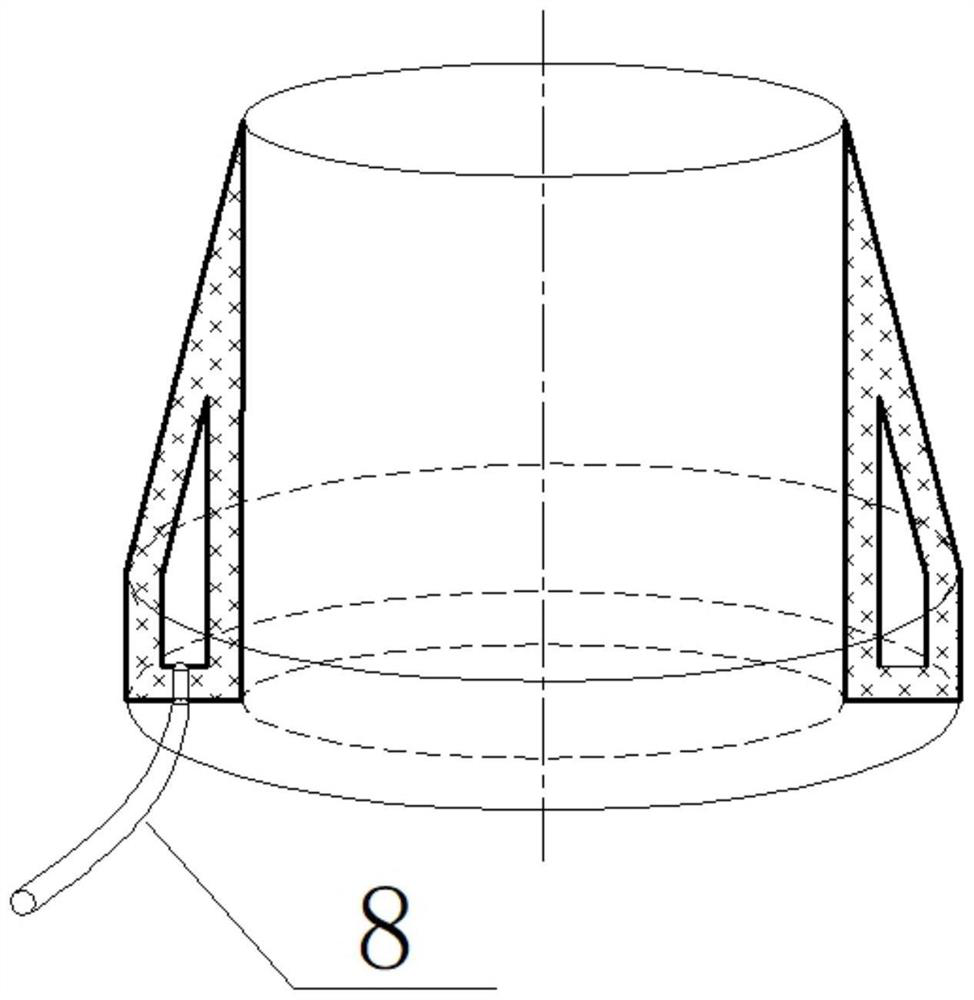

[0034]Under the protection of the guide protective cover 13, push the grouting integrated pipe 9 and the exhaust grouting compound end 4 to the predetermined position, inflate the inflatable elastic grout stopper 10, fix the grouting integrated pipe 9 and the exhaust grouting compound The connecting body of the terminal 4 is sealed in the bore 16. During grouting, first use high-pressure gas to break through the sealing dust-proof film 14, so that the exhaust channel 12 can be unimpeded to exhaust. The grout enters the gap between the anchor rod 1 and the exhaust grouting compound end 4 through the grouting port 5, and then passes through the gap between the exhaust grouting integrated pipe 9 and the anchor rod 1, and flows into the exhaust grouting grouting hole 11. Between the slurry pipe 9 and the borehole 16, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com