Method for constructing advance support anchor rod on tunnel face of soft rock section with hole easy to collapse

A technology of advanced support and bolt construction, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problem that the insertion effect of glass fiber bolts is greatly reduced, the quality cannot be guaranteed, and the face collapses. problems, to achieve the effect of saving the amount of bolts and drilling holes, saving the sealing materials, and ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

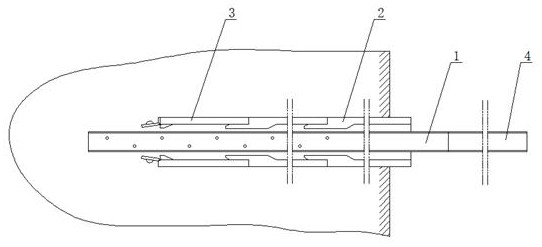

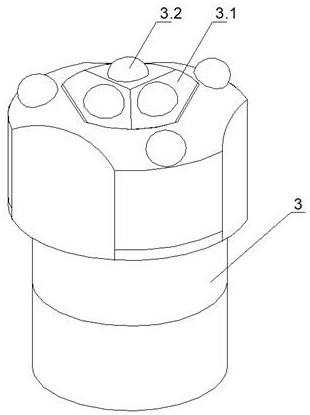

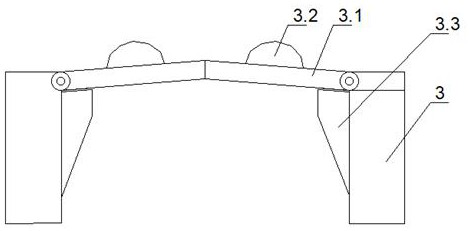

[0022] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings. The content shown in each figure is only used to understand the technical content of the invention, and does not represent the actual scale and real shape of the product, wherein the same reference numerals indicate parts with the same structure or the same function but similar structures.

[0023] In this text, "parallel", "perpendicular" and the like are not limitations in strict mathematical and / or geometric senses, and may also include errors that can be understood by those skilled in the art and allowable when manufacturing or using the product. In addition, "perpendicular" includes not only the mutual perpendicularity when two objects are directly in contact with each other in space, but also the mutual perpendicularity when two objects a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com