Three-cutting crushing pump

A technology for crushing pumps and cutting wheels, which is applied in the direction of pumps for special fluids, pumps, and parts of pumping devices for elastic fluids, etc. , vibration or increased shaft power, etc., to achieve the effect of improving cutting effect, equalizing resistance and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

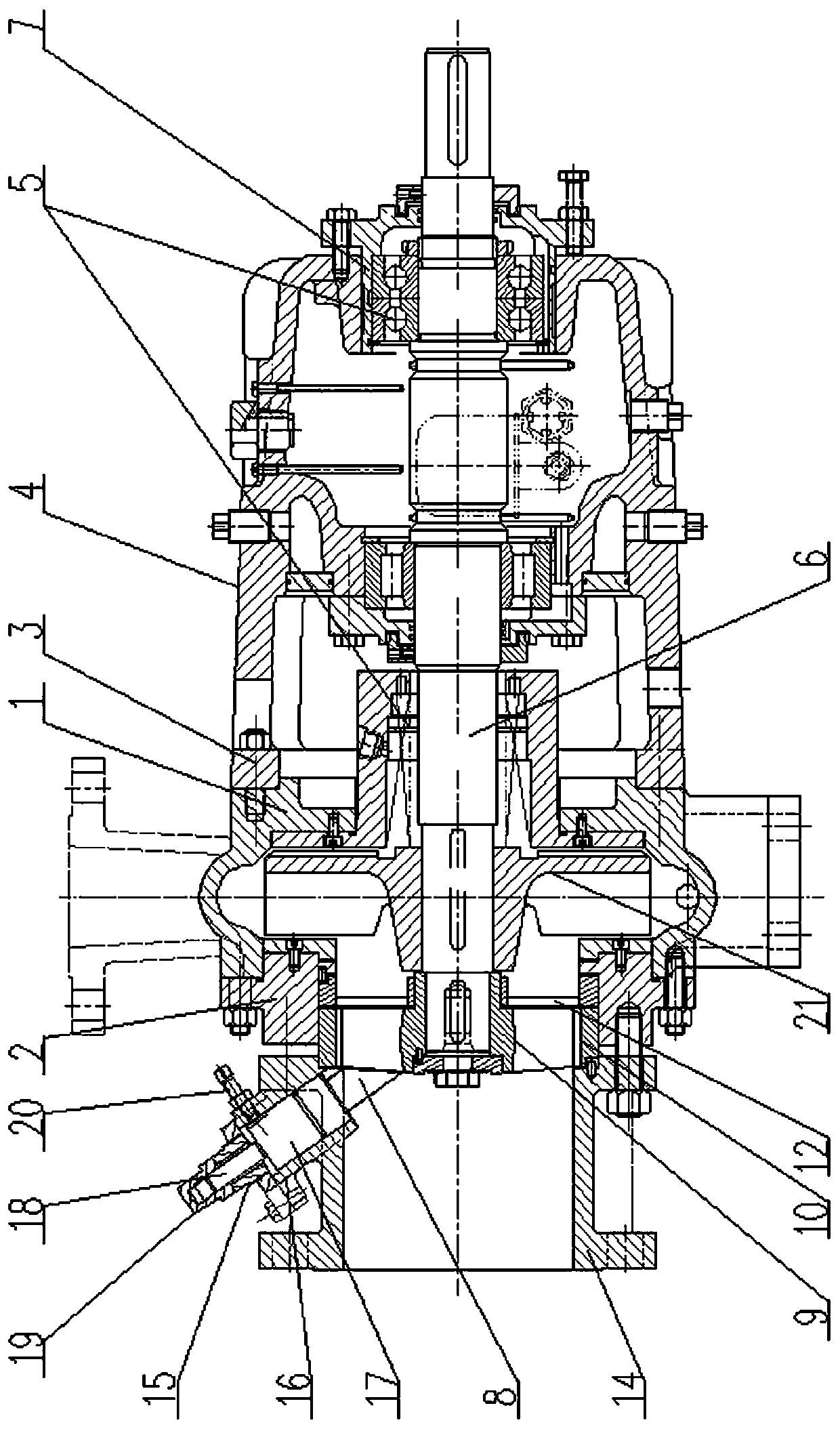

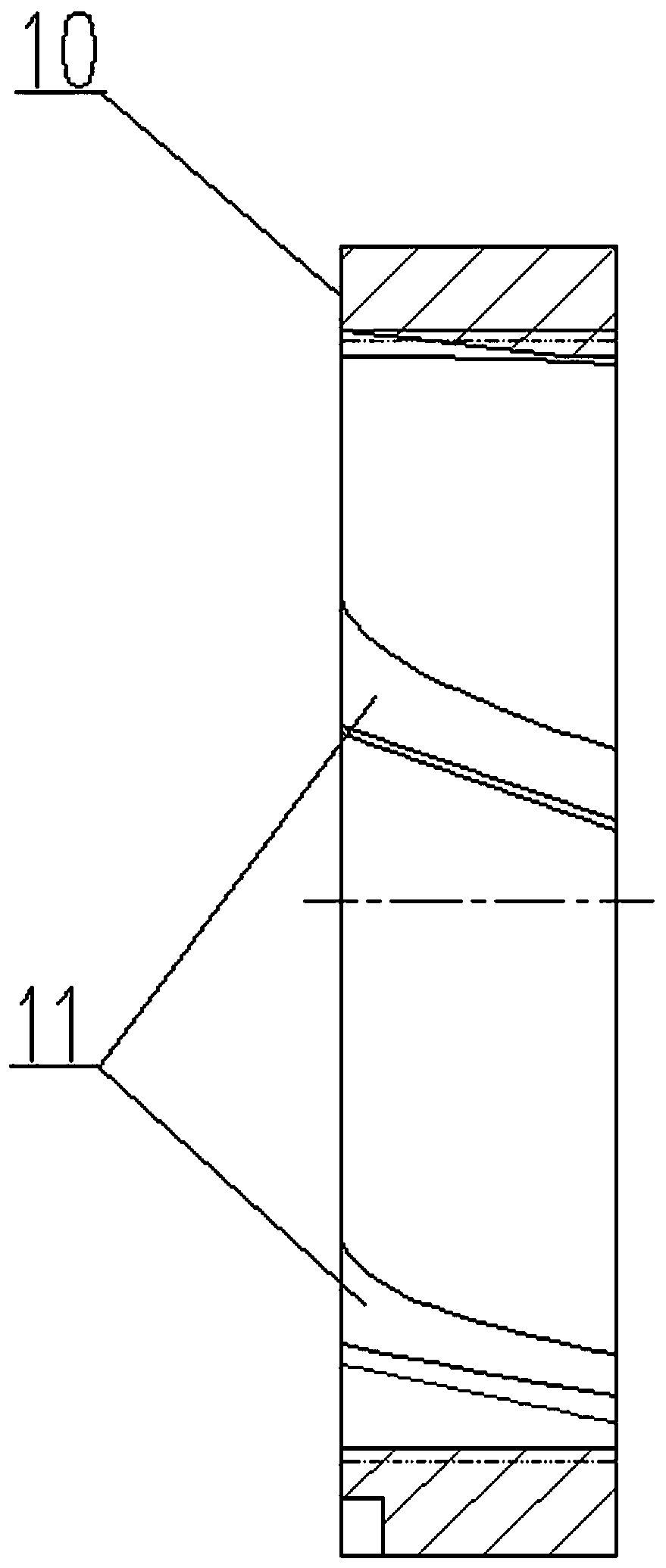

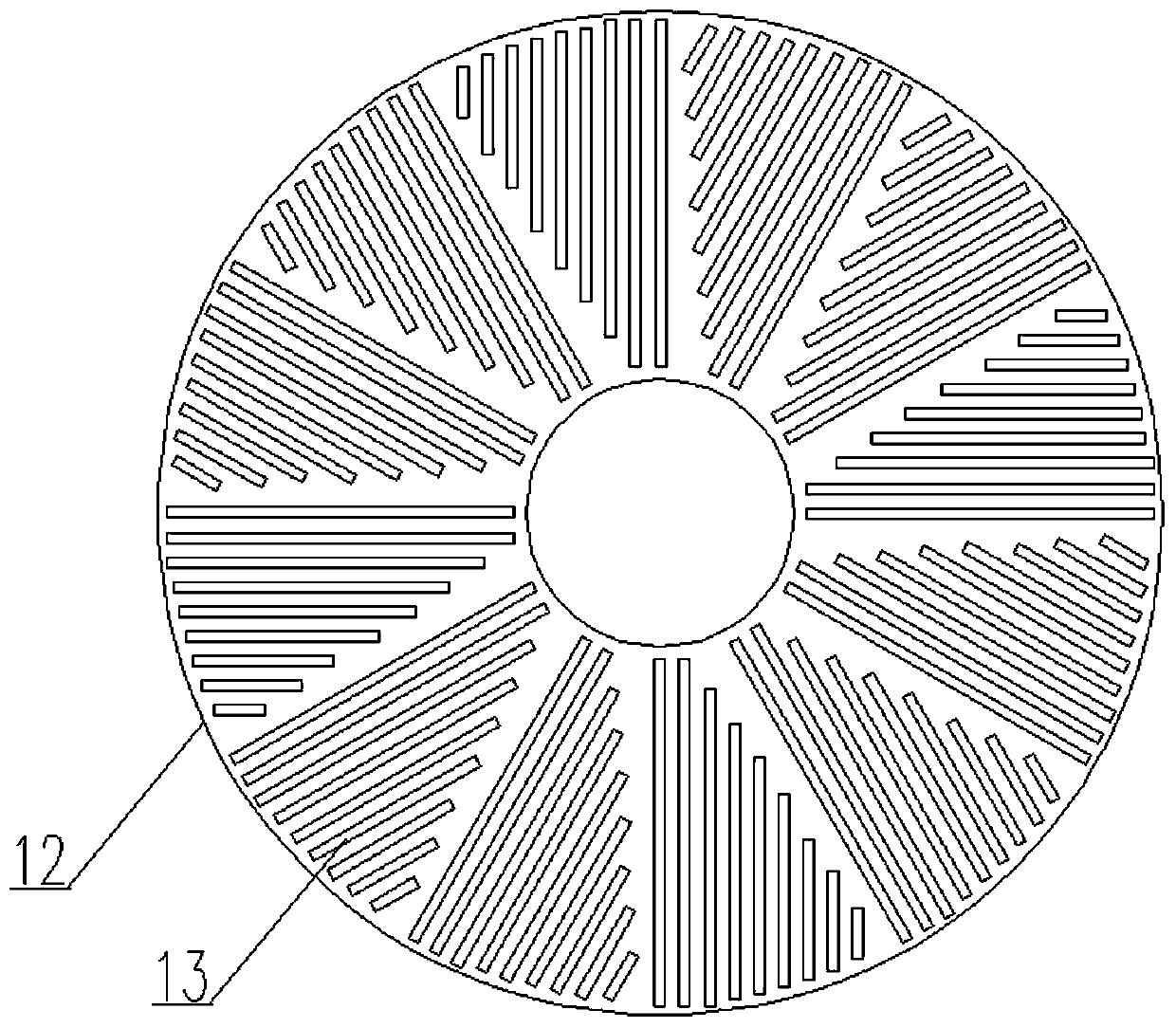

[0023] Figure 1-3 The embodiment shown is a crushing pump with three cuts, including a pump body 1, a front pump cover 2, a rear pump cover 3, a spindle box 4, a bearing 5, a pump shaft 6, a bearing sleeve 7, a cutter 8, and a cutting wheel 9 , Cutting sleeve 10, grid plate 12, suction pipe 14, cutter seat 15. The pump shaft 6 is supported in the main shaft box 4 through the bearing 5. One end of the pump shaft extends into the inner cavity of the pump body 1 encapsulated by the front and rear pump covers 2 and 3 and the impeller 21 in the connector. The other end of the pump shaft is supported on the bearing by the bearing. In the sleeve 7, the headstock 4 is encapsulated by the end cover of the bearing sleeve, and a plurality of end cover adjustment screws and a plurality of end cover locking screws are evenly distributed on the circumference of the end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com