Descaling and water channel cleaning system of steam generator.

A steam generator and cleaning system technology, which is applied in the field of kitchen steam oven appliances, can solve the problems that the steam generator in the steam oven cannot be automatically descaled and waterway cleaning, affects the service life of the steam generator, and cannot be cleaned manually, achieving intelligent The effects of descaling waterway cleaning, reducing bacterial growth, and improving connection strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

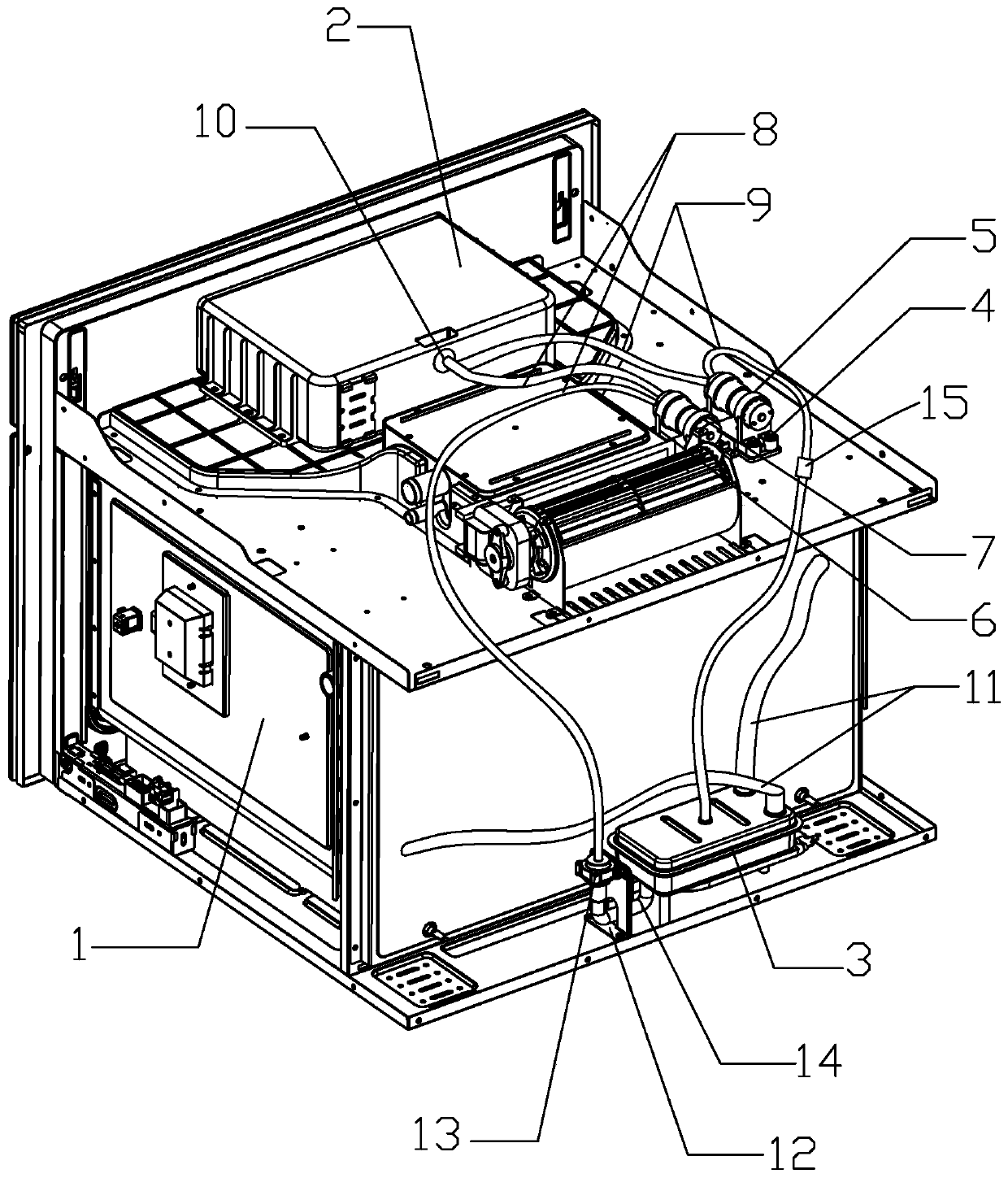

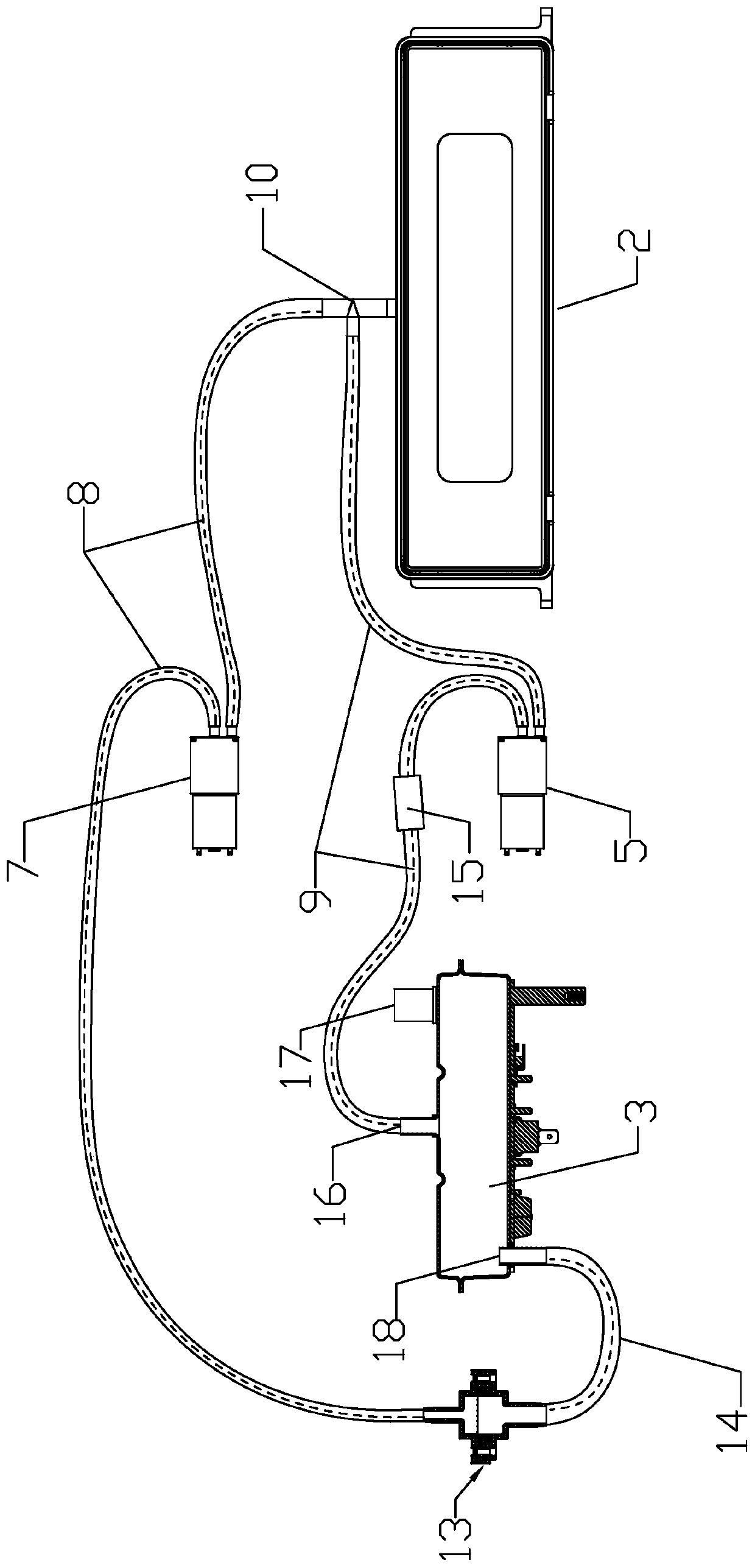

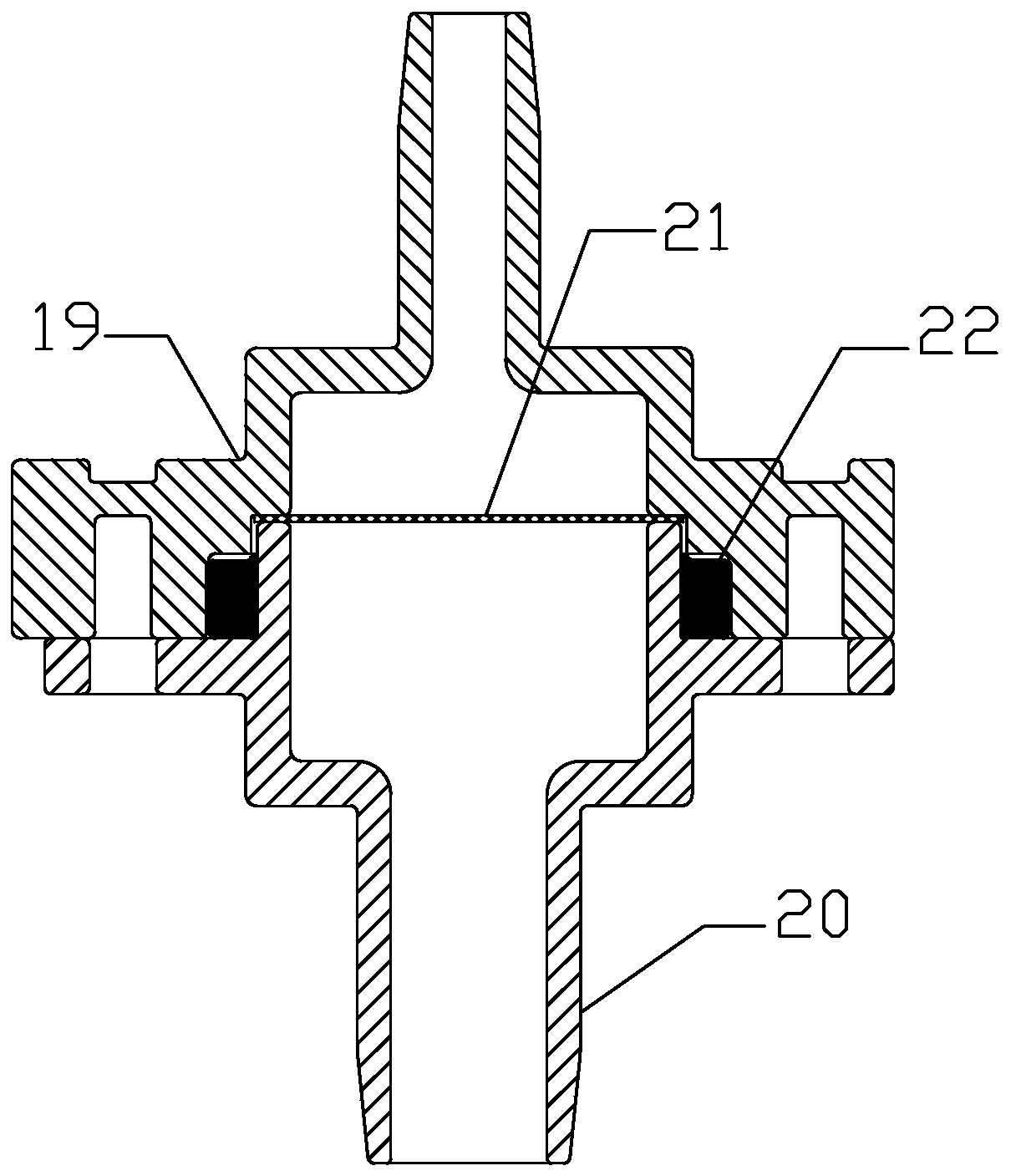

[0027] Such as Figure 1 to Figure 3 As shown, it is a steam generator descaling and waterway cleaning system according to the present invention, which includes a water tank 2 and a steam generator 3. The water tank 2 and the steam generator 3 are respectively arranged on the top surface and the bottom of the rear side of the body 1. The water component and the return water component, the water tank 2 is connected to the steam generator 3 through the water inlet component and the return water component, and both the water inlet component and the return water component are connected to the water tank 2 through the water tank tee joint 10, and the water tank tee joint 10 not only simplifies the inlet The connecting pipeline between the water component, the return water component and the water tank 2 can realize the time-segmented work of the water inlet component and the return water component. Through the design of the return water component, the intelligent descaling and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com