Stainless steel food cooling rack

A cooling rack, stainless steel technology, applied in food science, baked food processing, baking, etc., can solve the problems affecting the taste of cooked food, affecting the cooling speed of cooked food in the lower layer, and achieve the effect of accelerating the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

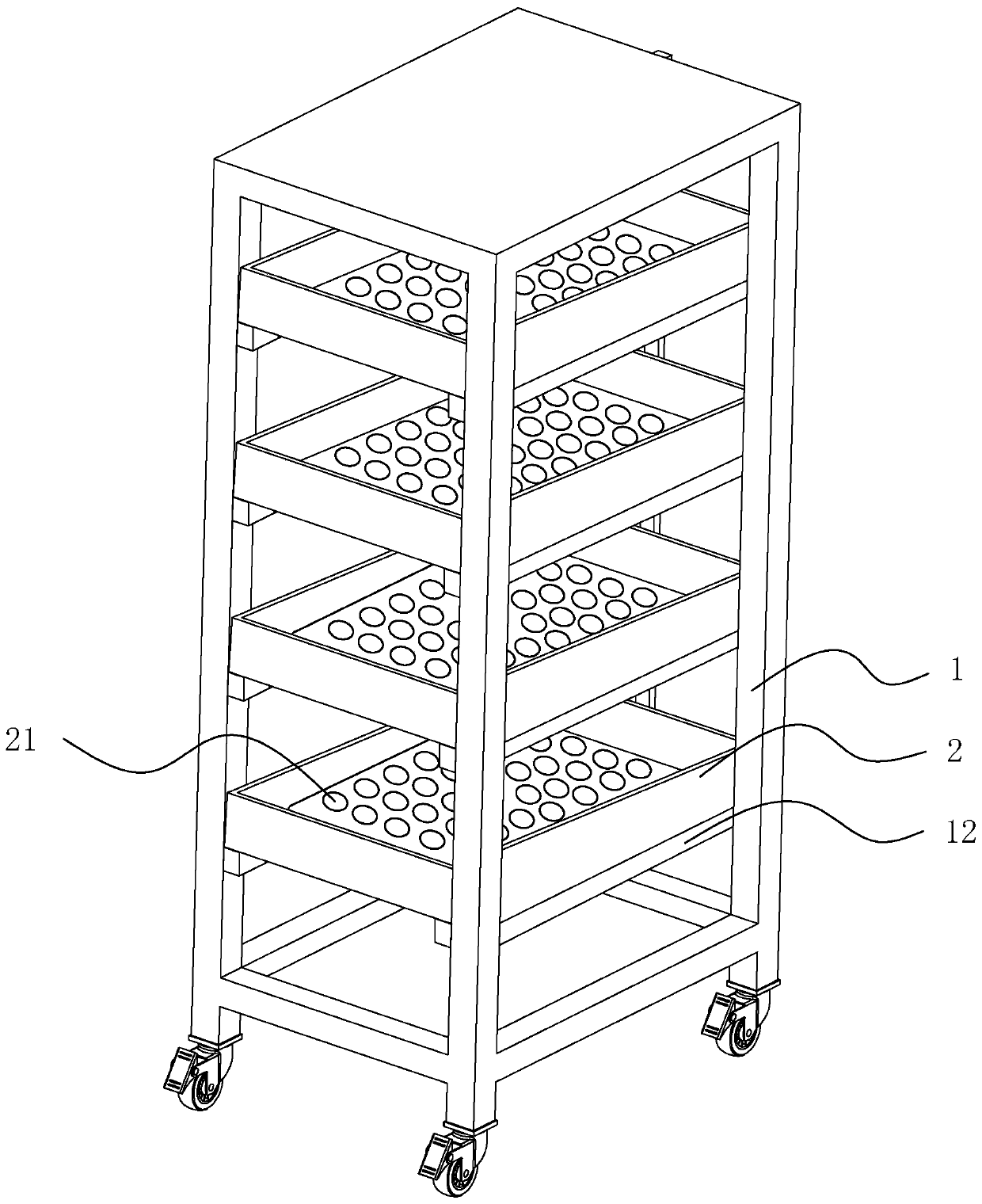

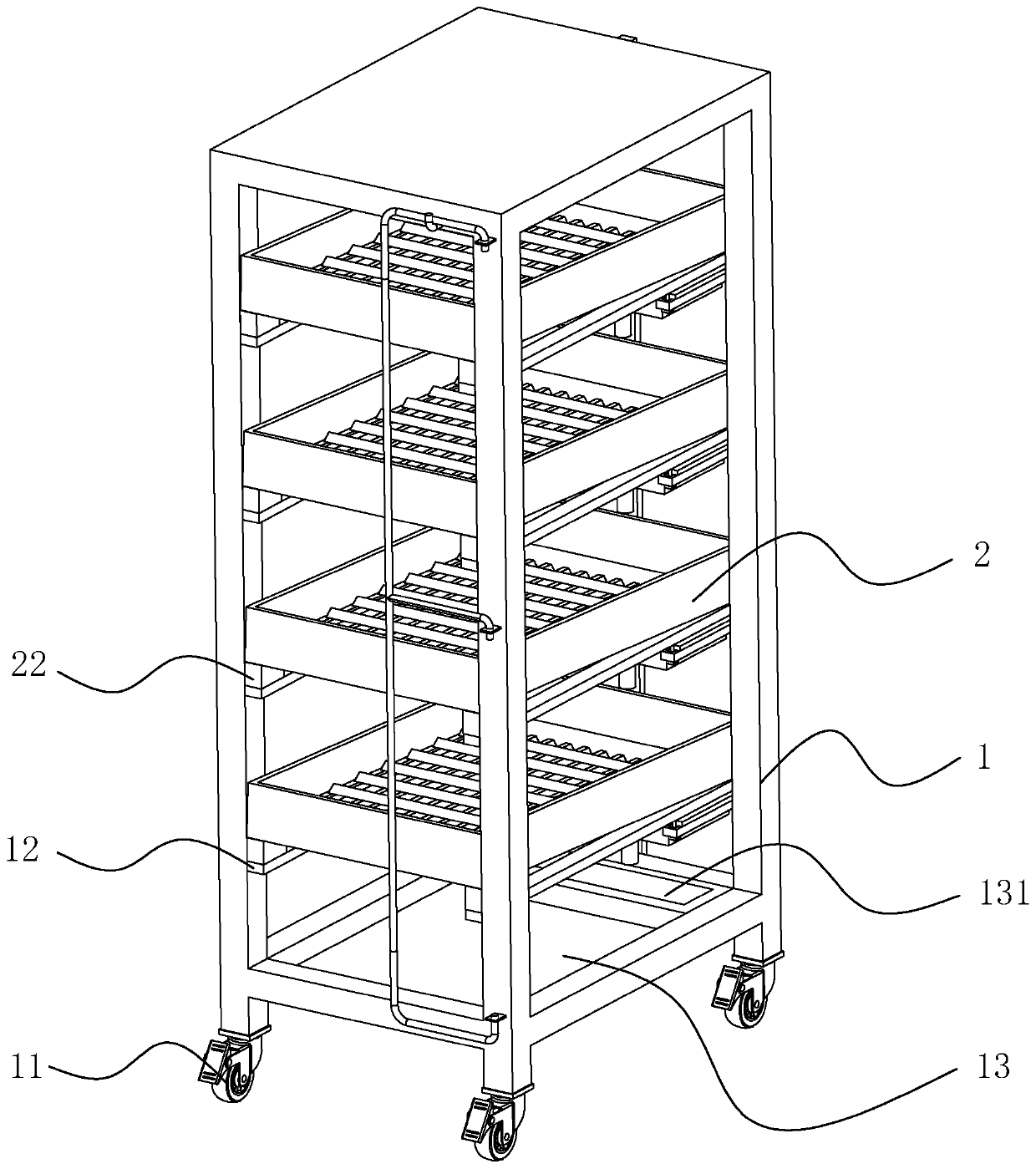

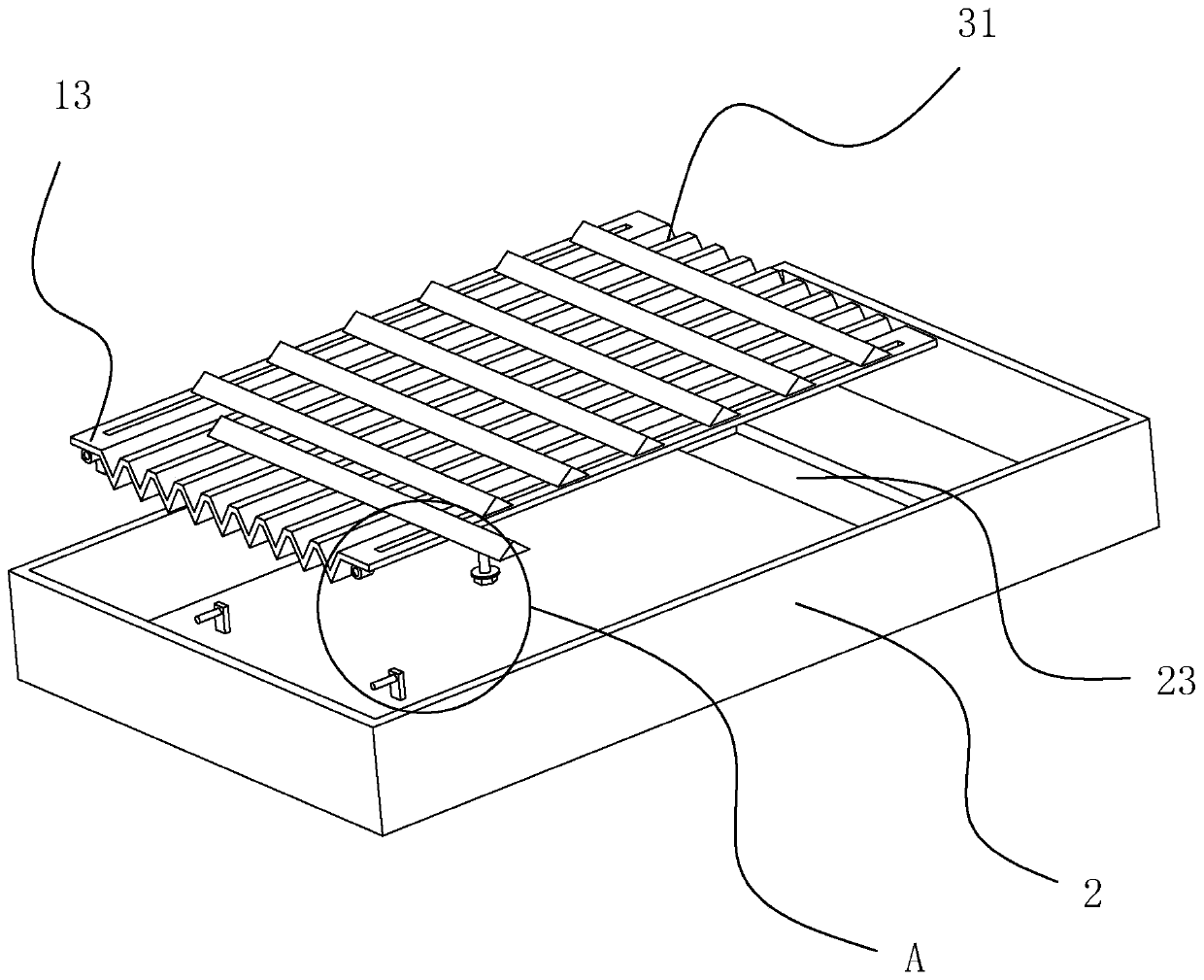

[0041] A stainless steel food cooling rack, cf. figure 1 and figure 2 , which includes a bracket 1 made of stainless steel and a number of cooling plates 2, the lower end of the bracket 1 is fixedly connected with a universal wheel 11 for driving the bracket 1 to move; distribution, the bracket 1 is welded with a number of load-bearing rods 12 against the cooling plate 2, the load-bearing rods 12 are located below the cooling plate 2, and are fixed on the bracket 1 by welding; A spacer 22, preferably rubber of the spacer 22, two spacers 22 are respectively located on both sides of the cooling plate 2, and the side of the spacer 22 away from the cooling plate 2 is abutted against the load-bearing rod 12, so that the cooling plate 2 and the horizontal The surface is inclined; and some cooling plates 2 are provided with oil outlet holes 23 at one end away from the cushion block 22; a chassis 3 is arranged in the cooling plate 2, and the material of the chassis 3 is preferably s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap