Solution concentration device and achievement method thereof

A solution concentration and concentration tank technology, which is applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of high temperature and low temperature without linkage, high-quality energy consumption, etc., and achieve simple structure, remarkable energy-saving effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

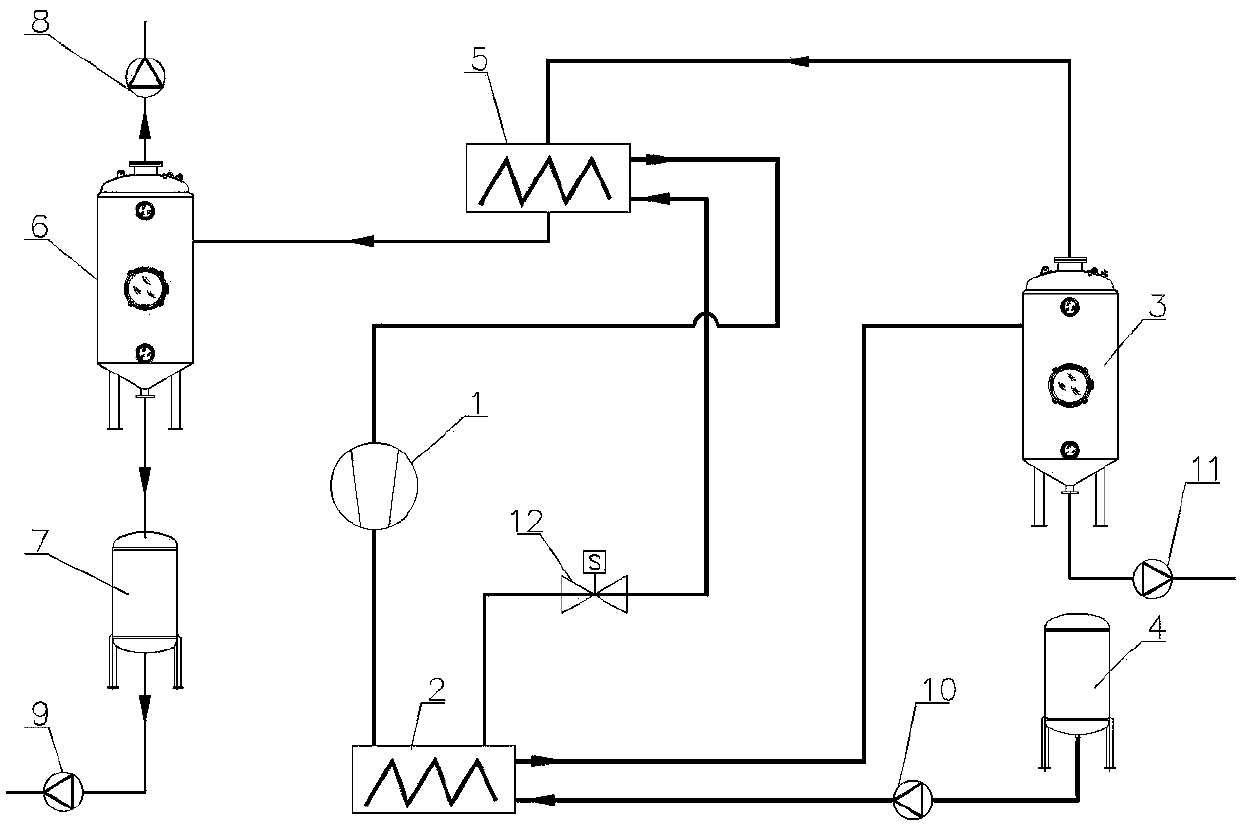

[0023] Such as figure 1 Shown, the solution concentration device of the present invention, it comprises stoste evaporator 2, concentration tank 3, stoste tank 4, solvent recovery condenser 5, gas-liquid separator 6 and solvent collection tank 7; The input end of stoste evaporator 2 and The output of the stock solution tank 4 is connected, the output of the stock solution evaporator 2 is connected with the input of the concentration tank 3, the stock solution evaporator 2 is connected with the solvent recovery condenser 5 through a compressor 1, and the output of the concentration tank 3 Connect with the solvent recovery condenser 5, the output end of the solvent recovery condenser 5 is connected with the gas-liquid separator 6, the output end of the gas-liquid separator 6 is connected with the solvent collection tank 7, and the bottom of the concentration tank 3 is provided with an outlet Feed pump 11.

[0024] In this embodiment, the output end of the raw liquid evaporator 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap