Skylight splicing and welding machine

A welding machine and skylight technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of workpiece positioning tooling welding seam tracking not meeting the requirements, low efficiency, and unable to meet the high-precision processing needs of modern tailor welding processing And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described below in conjunction with accompanying drawing.

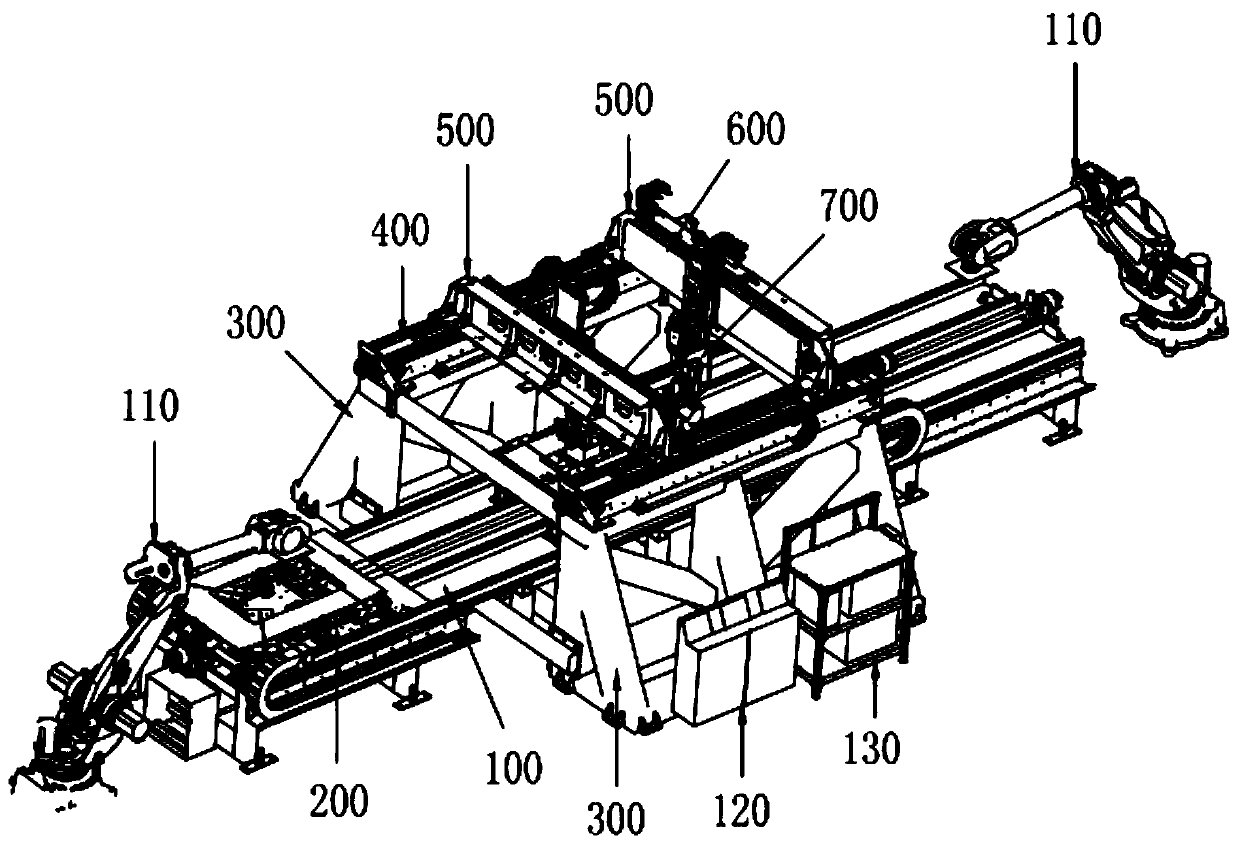

[0026] as attached figure 1 As shown, a skylight tailor welding machine according to the present invention includes a feeding mechanism 100 and a gantry frame, and the feeding mechanism 100 passes through the gantry frame; the middle part of the feeding mechanism 100 is a welding station, and the two ends are loading and unloading stations , a set of loading and unloading robots 110 are arranged at both ends of the feeding mechanism 100, and a suction cup frame is arranged on the loading and unloading robot 110. Set the workpiece positioning workbench 200, and the feeding mechanism 100 drives the workpiece positioning workbench 200 to move between the loading and unloading station and the welding station through the servo motor, screw rod and linear slide rail.

[0027] The gantry frame includes a gantry base 300, a gantry drive mechanism 400 and two groups of gantry frames 500. An ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com