Silk ingot receiving and stacking system

A silk ingot and stacking technology, which is applied in the field of silk ingots, can solve the problems of high equipment cost of the silk ingot receiving and stacking system, and achieve the effects of intelligent receiving and stacking work, simple structure, and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

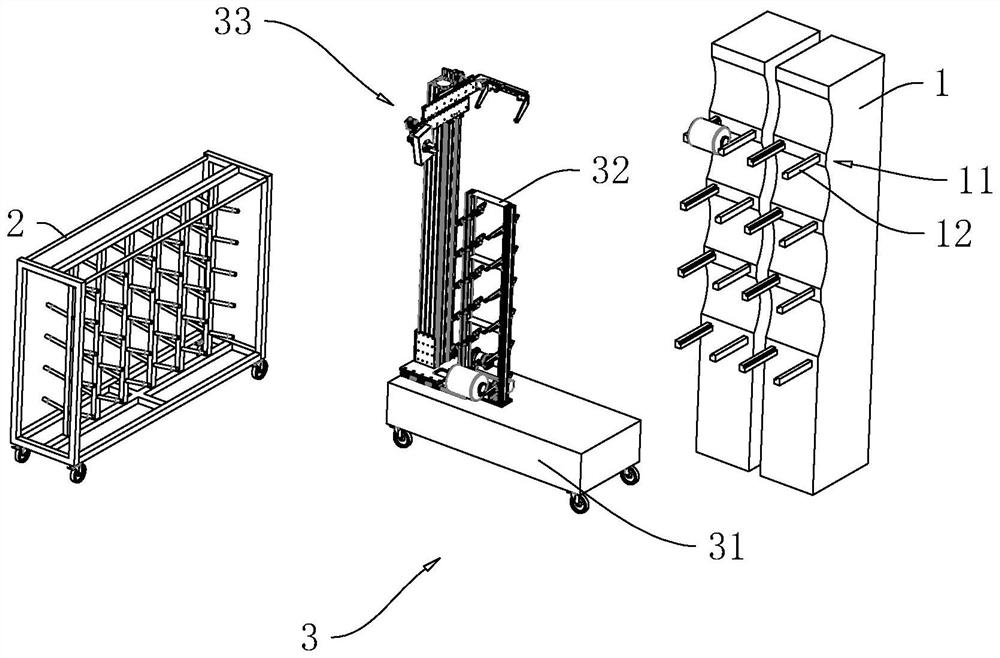

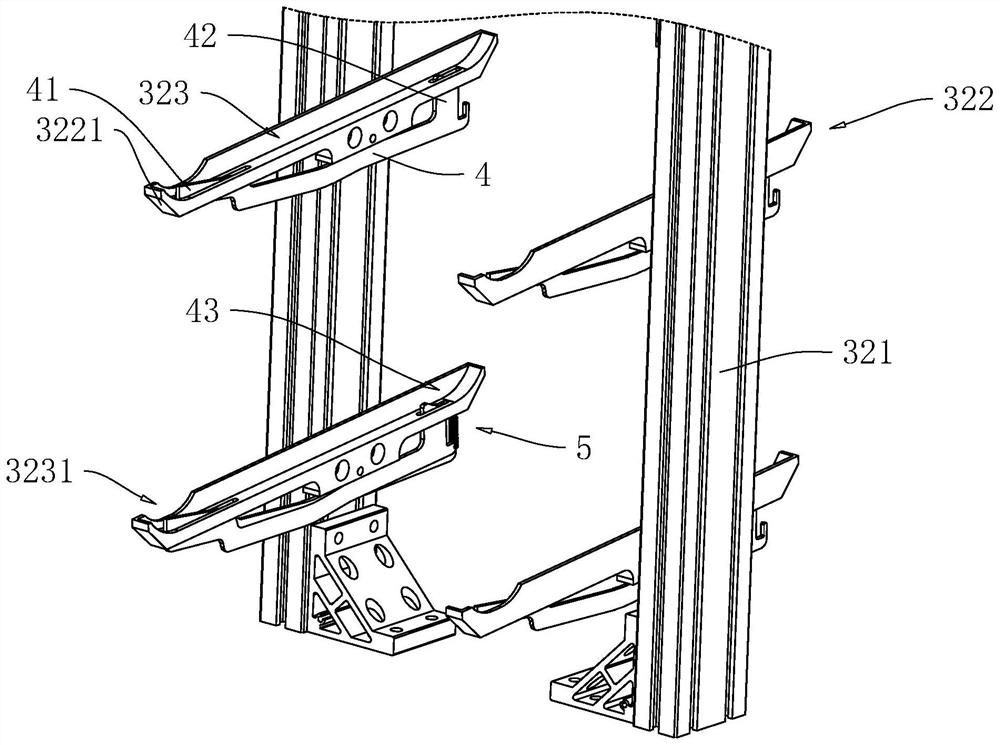

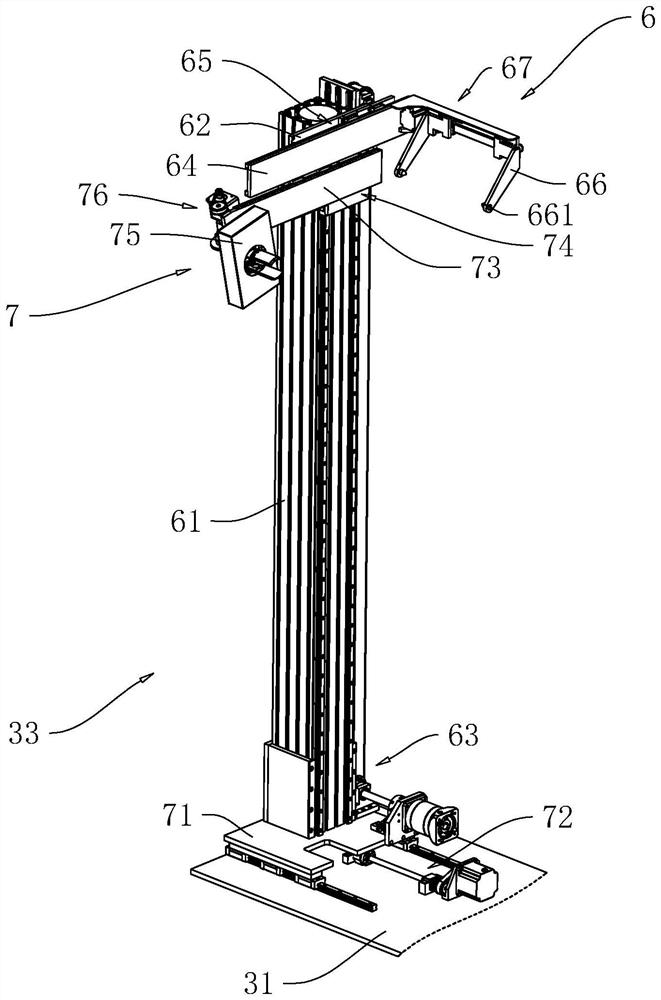

[0057] Attached to the following Figure 1-5 This application will be described in further detail.

[0058] The embodiment of the present application discloses a wire ingot receiving and stacking system. refer to figure 1 , the wire ingot receiving and stacking system includes wire ingot elasticizing and winding equipment 1, ingot car 2 and handling equipment 3. Specifically, the ingot elasticizing and winding equipment 1 is usually installed in the workshop, and the wire ingot is elastically wound. There are a plurality of equipment 1, and each wire ingot texturing and winding equipment 1 has a discharge port 11, and the plurality of discharge ports 11 are distributed in a rectangular array; the spindle car 2 is also installed in the workshop, and the wire The ingot car 2 is usually at a position far away from the ingot bouncing and winding device 1; the handling device 3 includes a moving mechanism 31, a wire ingot temporary rack 32 and a transfer manipulator 33, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com