Emergency device for accidents in hydration workshop of thermal power plant

An emergency device and thermal power plant technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as untimely handling of accidents and impact on personnel health, and achieve the effects of convenient operation, improved efficiency, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

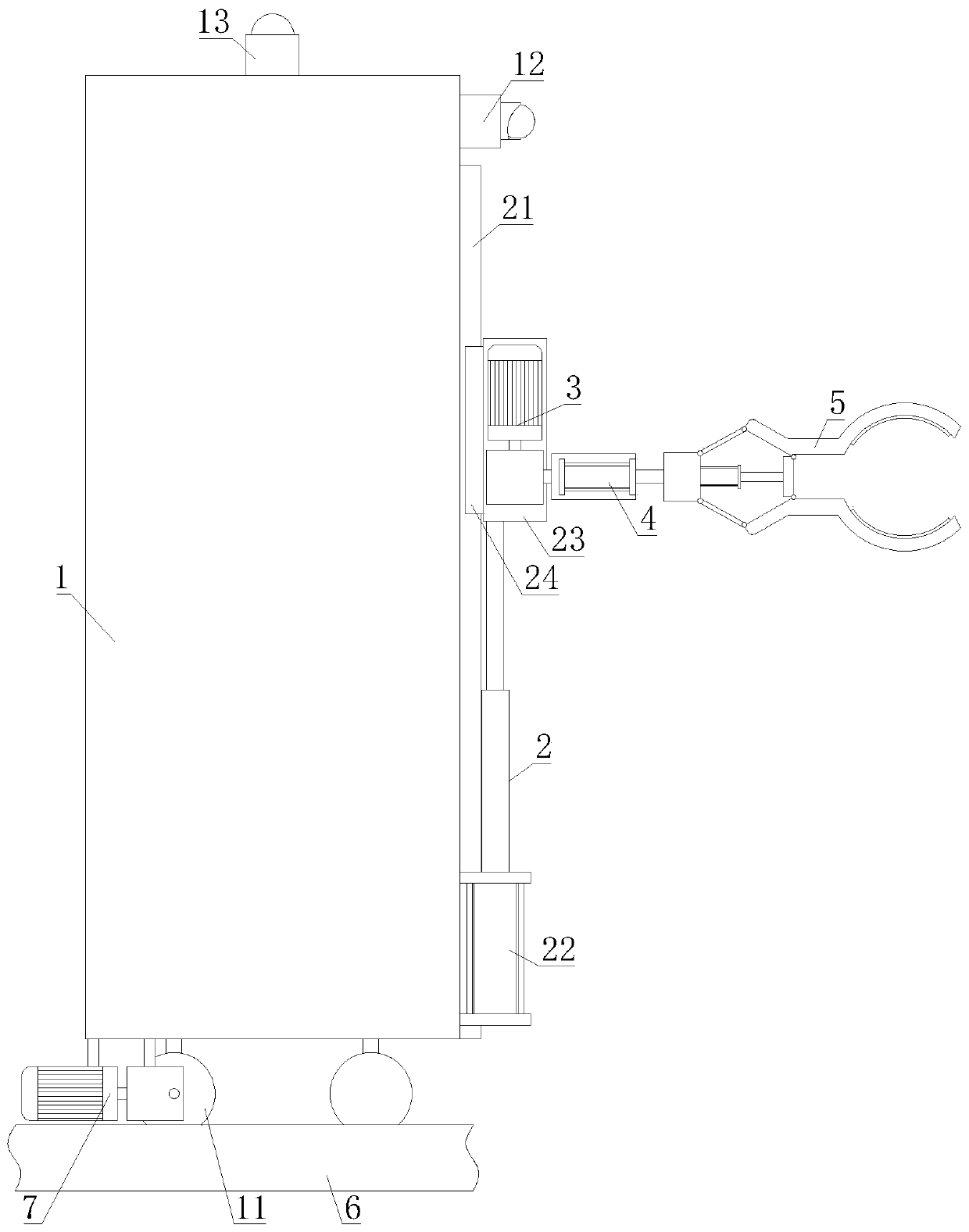

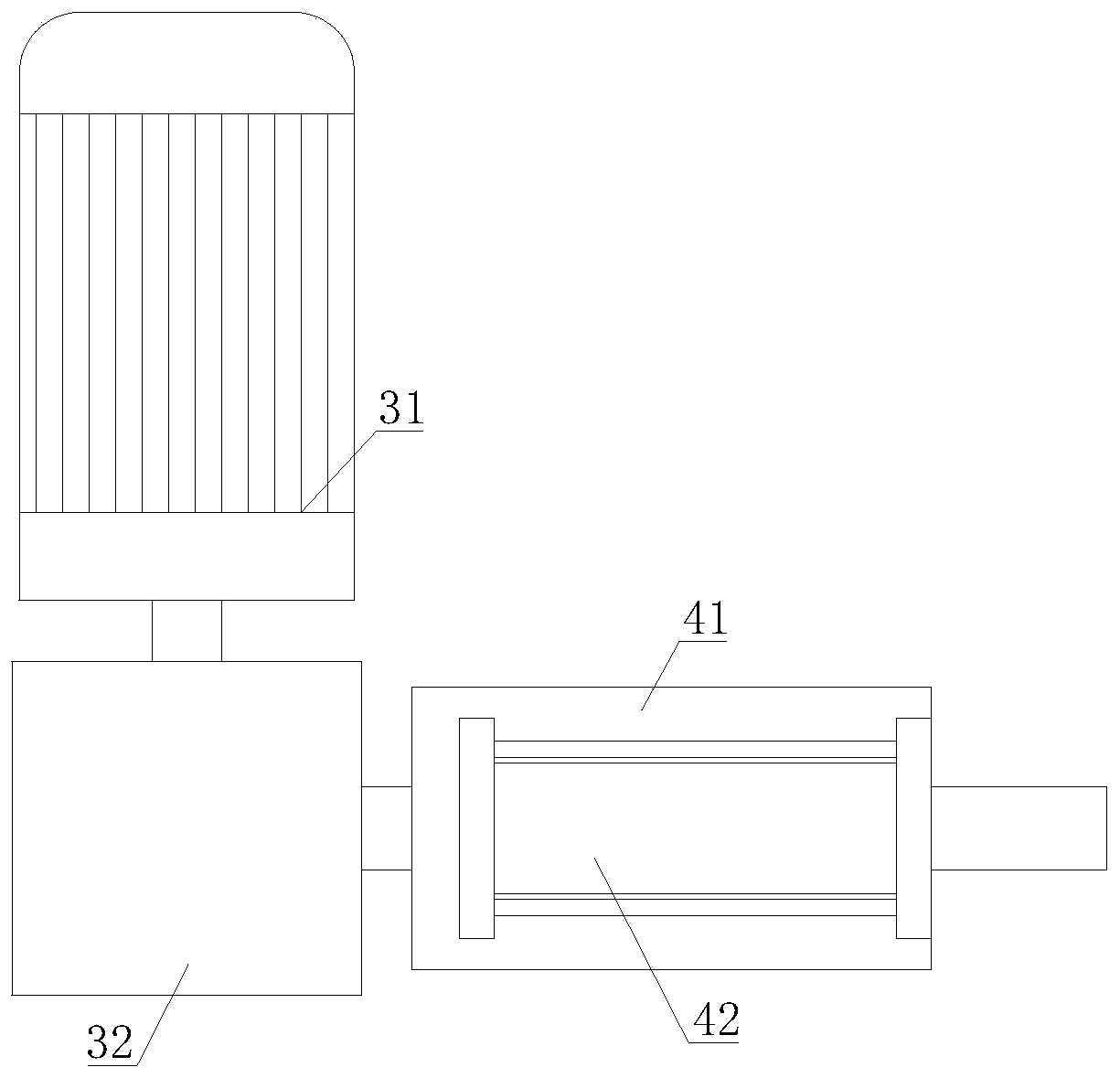

[0033] The accident emergency device in the hydration workshop of the thermal power plant includes an emergency box 1. The emergency box 1 is provided with a lifting mechanism 2. The lifting mechanism 2 is connected with a rotation drive mechanism 3. The output shaft of the rotation drive mechanism 3 is connected with a telescopic mechanism 4. The telescopic mechanism 4 The output end of the valve is connected with a valve closing manipulator 5 for clamping the valve.

[0034] When there is an accident such as leakage in the hydration workshop, the valve closing manipulator 5 can clamp the valve of the hydration workshop, and the rotating drive mechanism 3 drives the valve closing manipulator 5 to rotate, then the valve closing manipulator 5 can close the valve to ensure that the accident can be solved immediately. deal with. The valve is processed by the valve closing manipulator 5, which avoids manual operation and ensures the safety of staff. Moreover, the valve is automat...

Embodiment 2

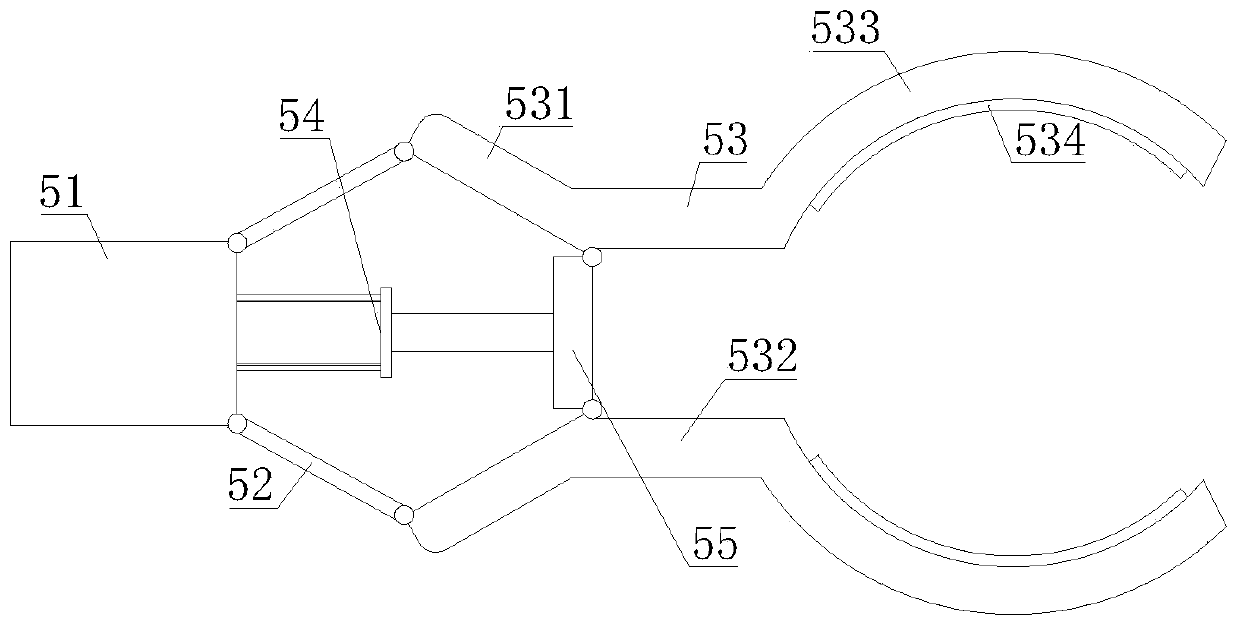

[0036] On the basis of Embodiment 1, the valve-closing manipulator 5 includes a fixed block 51, which is fixed on the output end of the telescopic mechanism 4, and two connecting rods 52 are respectively hinged on the fixed block 51, and the other end of the connecting rod 52 Clamping claw 53 is hinged; Clamping cylinder 54 is installed on the fixed block 51, is fixed with dialing block 55 on the piston rod of clamping cylinder 54, and the middle part of two clamping claws 53 is all hinged with dialing block 55.

[0037] When the clamping cylinder 54 pulls back the dial block 55, under the joint action of the connecting rod 52 and the dial block 55, the two clamping claws 53 tilt towards each other, and the clamping claws 53 clamp the valve, thereby facilitating The valve is tightened. When the clamping cylinder 54 pushes the dial block 55 out, the two clamping claws 53 will tilt towards each other under the joint action of the connecting rod 52 and the dialing block 55, and t...

Embodiment 3

[0039] On the basis of Embodiment 1 or Embodiment 2, the clamping claw 53 includes a tilting section 531, one end of the tilting section 531 is hinged with the connecting rod 52, and the other end of the tilting section 531 is fixed with a connecting section 532. The turning block 55 is hinged to one end of the connecting section 532 close to the tilting section 531 , the other end of the connecting section 532 is fixed with an arc splint 533 , and a rubber gasket 534 is fixed inside the arc splint 533 .

[0040] The curved splint 533 can be better attached to the valve to ensure that the valve can be clamped and improve the accuracy of valve opening and closing.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap