High-strength stainless steel hollow composite plate for building construction or template and preparation method of composite plate

A technology of building construction and stainless steel, applied in the direction of chemical instruments and methods, laminated, layered products, etc., can solve the problems that cannot be applied to the fields of building construction and formwork, and cannot meet the load-bearing strength and life requirements of ordinary building wall panels or floor slabs, Low strength and other problems, to achieve high toughness, expand the scope and scene of adaptation, and reduce the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

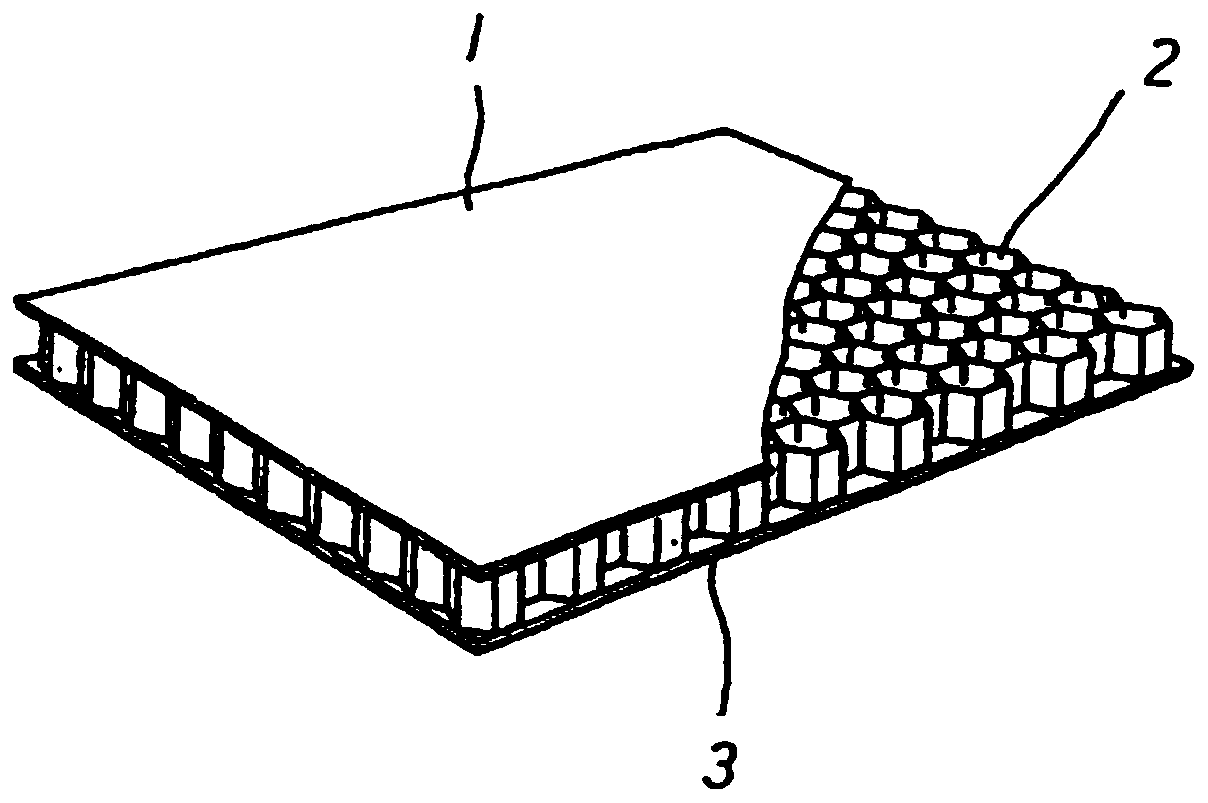

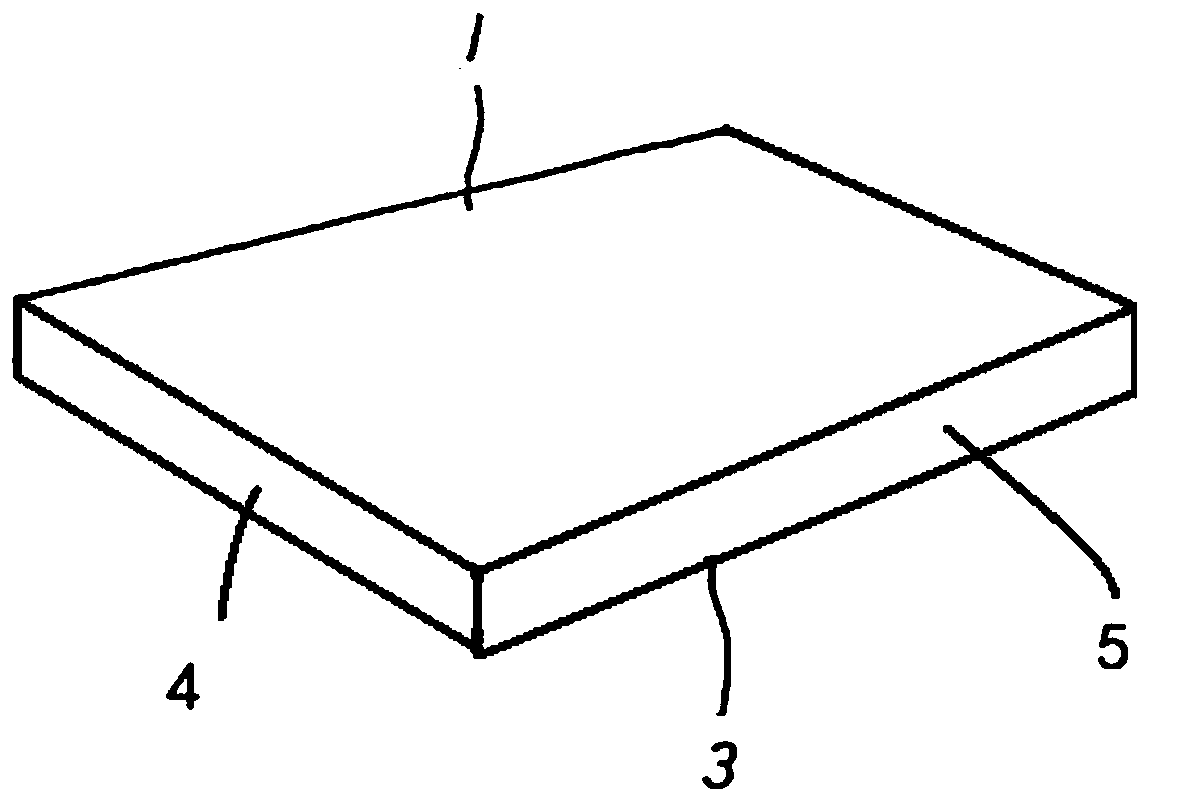

[0051] see Figure 1-2 , the invention provides a high-strength stainless steel hollow composite panel for building construction or formwork, characterized in that it comprises:

[0052] Stainless steel panel 1;

[0053] Stainless steel bottom plate 3;

[0054] A stainless steel honeycomb panel 2, which is arranged between the stainless steel panel 1 and the stainless steel bottom plate 3, and the stainless steel honeycomb panel 2 is integrally formed by molding; and

[0055] Stainless steel side plates 4, 5, which are arranged for edge sealing between the stainless steel panel 1 and the stainless steel bottom plate 3;

[0056] The chemical composition and mass fraction of the stainless steel panel 1, stainless steel bottom plate 3, stainless steel honeycomb panel 2 and stainless steel side panels 4 and 5 are: C 0.065~0.19, Si≤1, Mn≤1, P≤0.080, S≤0.015 , 13.00≤Cr≤15.00, 1.5≤Ni≤2.2, Mo≤0.15, Cu≤0.25, the balance is Fe;

[0057] The high-strength stainless steel hollow compo...

Embodiment 2

[0082] see Figure 1-2 , the invention provides a high-strength stainless steel hollow composite panel for building construction or formwork, characterized in that it comprises:

[0083] Stainless steel panel 1;

[0084] Stainless steel bottom plate 3;

[0085] A stainless steel honeycomb panel 2, which is arranged between the stainless steel panel 1 and the stainless steel bottom plate 3, and the stainless steel honeycomb panel 2 is integrally formed by molding; and

[0086] The stainless steel side panels 4 and 5 are arranged between the stainless steel panel 1 and the stainless steel bottom panel 3 for edge sealing, and are arranged around the stainless steel honeycomb panel 2 .

[0087] Preferably, the wall thickness of the stainless steel panel 1 and the stainless steel bottom plate 3 is 0.5mm, the wall thickness of the honeycomb of the stainless steel honeycomb panel 2 is 0.5mm, the center distance of the honeycomb is 100mm, and the size of the honeycomb is

[0088]...

Embodiment 3

[0097] Preferably, see Figure 1-2 , the present invention also provides a high-strength stainless steel hollow composite panel for building construction or formwork, characterized in that it comprises:

[0098] Stainless steel panel 1;

[0099] Stainless steel bottom plate 3;

[0100] A stainless steel honeycomb panel 2, which is arranged between the stainless steel panel 1 and the stainless steel bottom plate 3, and the stainless steel honeycomb panel 2 is integrally formed by molding; and

[0101] The stainless steel side plates 4, 5 are arranged between the stainless steel panel 1 and the stainless steel bottom plate 3, and are arranged around the stainless steel honeycomb panel 2.

[0102]Preferably, the chemical composition and mass fraction of the stainless steel panel 1, stainless steel bottom plate 3, stainless steel honeycomb panel 2 and stainless steel side panels 4, 5 are: C 0.065~0.19, Si≤1, Mn≤1, P≤0.080, S≤0.015, 13.00≤Cr≤15.00, 1.5≤Ni≤2.2, Mo≤0.15, Cu≤0.25, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com