Biobased self-adhesive shrink barrier film

A barrier film, bio-based technology, applied in the field of bio-based self-adhesive shrinkage barrier film, can solve problems such as insufficient degradation, and achieve the effects of high cost performance, strong processability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

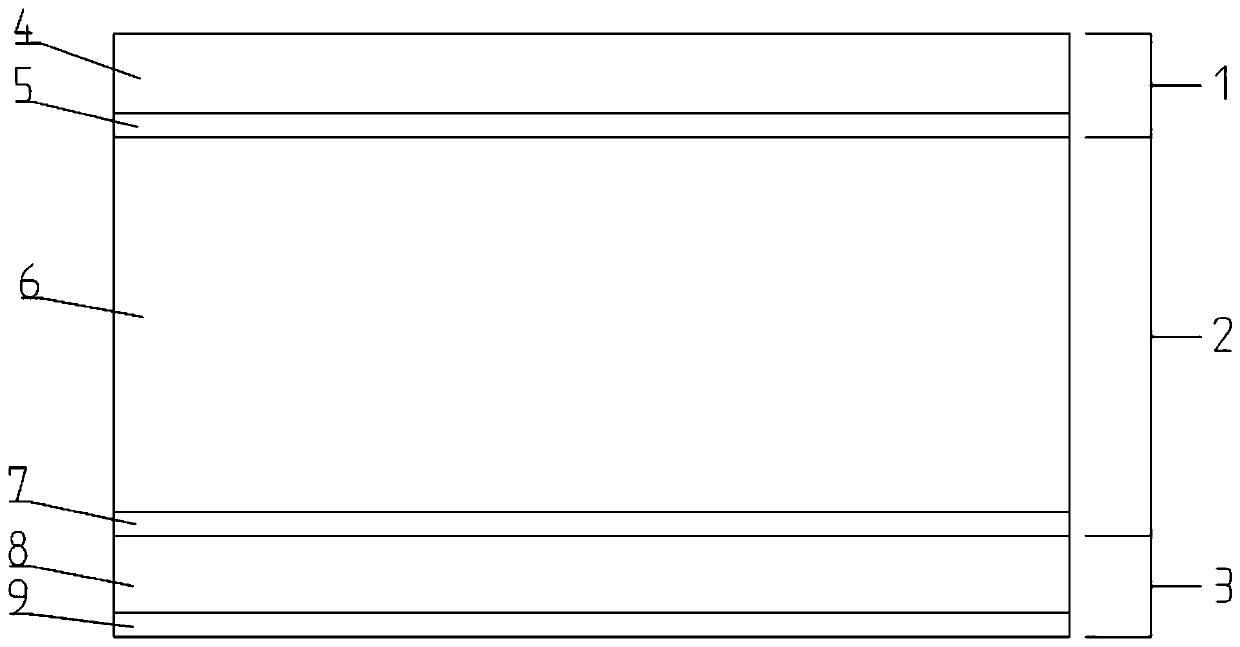

[0024] A bio-based self-adhesive shrinkage barrier film, comprising a surface layer 1, a middle layer 2, and an inner layer 3;

[0025] The surface layer 1 includes a surface resin layer 4 and a surface additive layer 5. The surface additive layer 5 is located below the surface resin layer 4. The surface resin layer 4 is a modified polylactic acid (SHQ-MLA) resin, and the surface additive layer 5 is controllable in water retention. Degradation (BSZJ) additives;

[0026] The middle layer 2 includes a middle resin layer 6 and a middle additive layer 7. The middle additive layer 7 is located below the middle resin layer 6. The middle resin layer 6 is a controllable degradation (JHSZ) resin of oxygen-containing polymer material, and the middle layer additive layer 7 is an oxygen-containing polymer. Olefin controlled degradation (HYZJ) additive;

[0027] The inner layer 3 includes an inner layer resin layer 8, an inner layer additive layer 9, the inner layer additive layer 9 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com