PLC controlled assembly line type full-automatic light-weight carrying device

An assembly-line, handling device technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as hidden dangers, high friction, and low efficiency, and achieve the effect of reducing hidden dangers and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

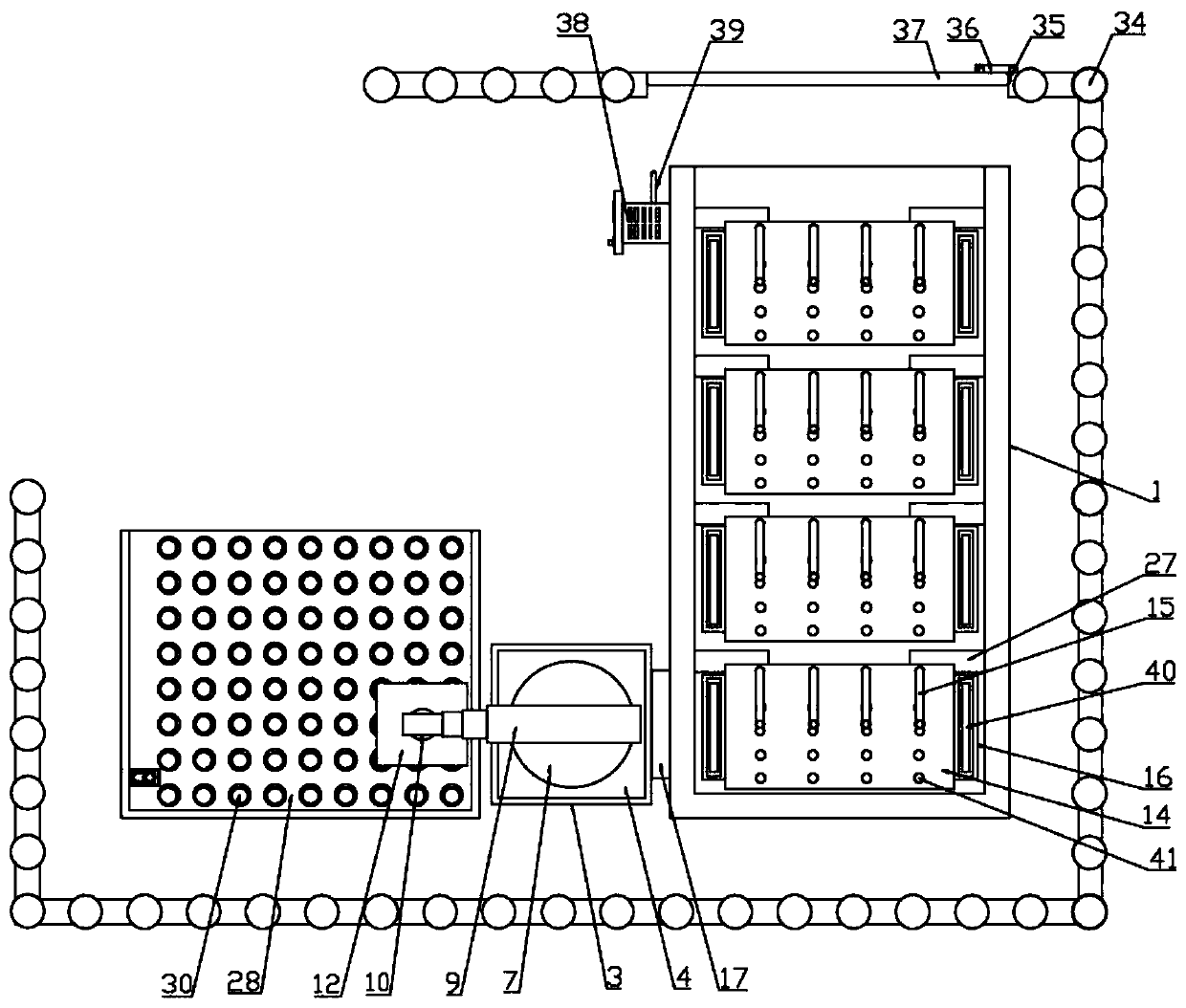

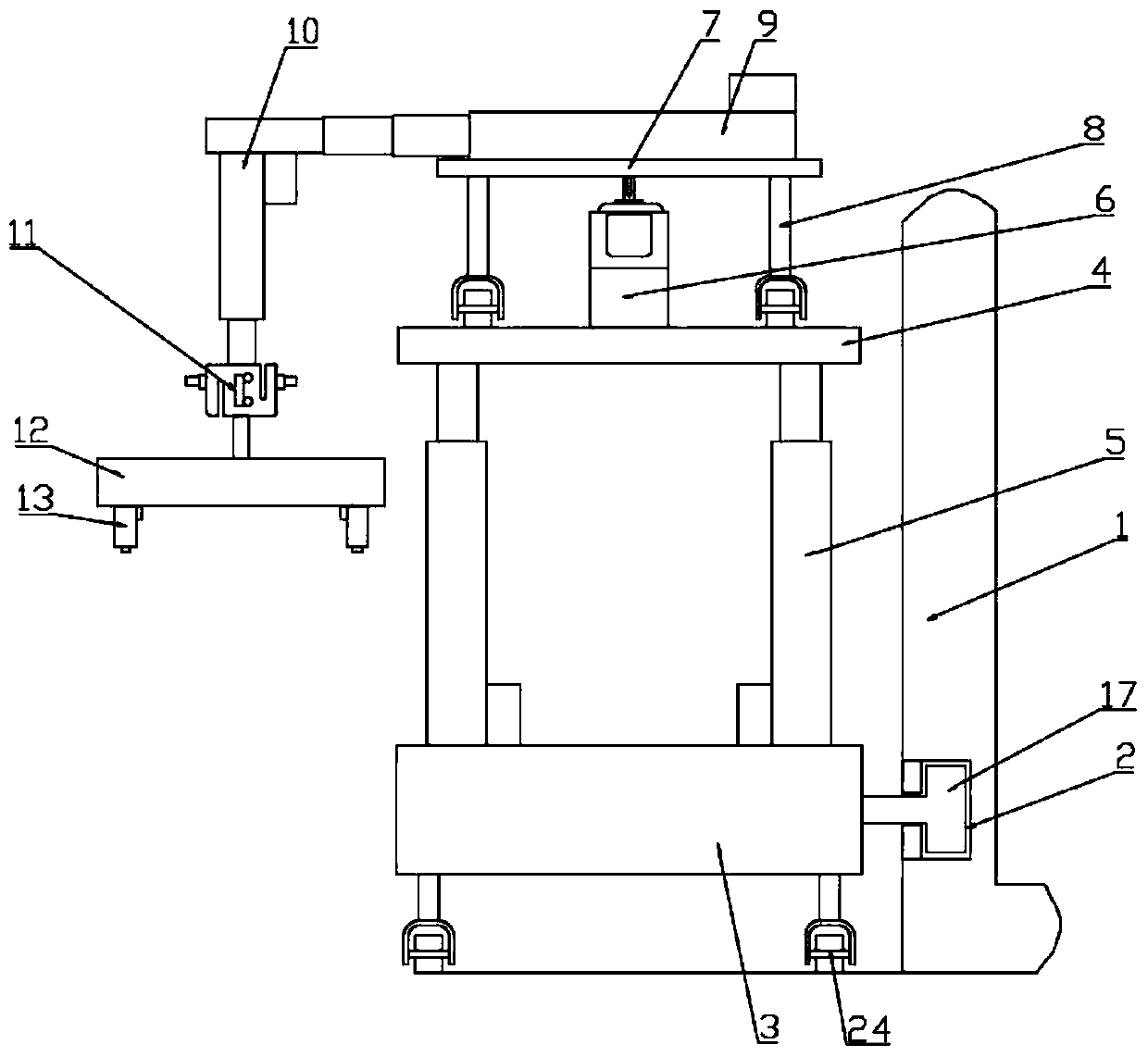

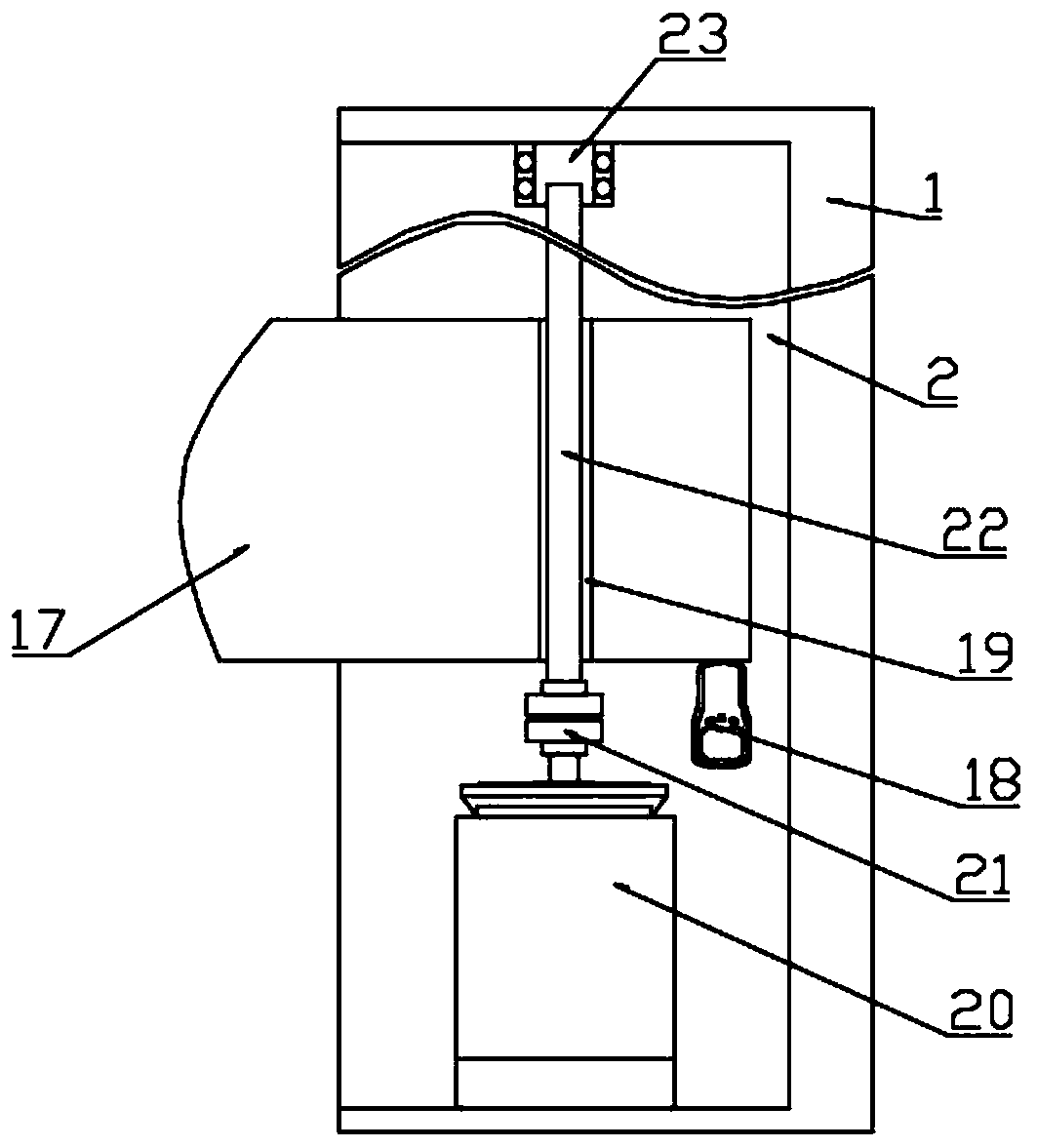

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 shown.

[0022] In this embodiment, it is controlled by the controller 38, the model of the controller 38 is TCC8810, and the power input end of the controller 38 is electrically connected with the industrial electrical interface so as to be energized. The industrial electrical interface is respectively connected to the first electric telescopic Rod 5, servo motor 6, multi-stage electric telescopic rod 9, second electric telescopic rod 10, electromagnet 13, rotating motor 20, are electrically connected and powered, and the control signal output end of controller 38 passes through and first electric telescopic rod Rod 5, servo motor 6, multi-stage electric telescopic rod 9, second electric telescopic rod 10, tension sensor 11, electromagnet 13, first infrared range finder 18, rotating motor 20, second infrared range finder 32 electric Connect and control its op...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap