Construction method of prefabricated outer wall cast-in-place section unilateral formwork of sandwich heat insulating plate with assembled structure

A technology of assembling structure and cast-in-place section, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., which can solve the problem of hole blocking and waterproof treatment. Problems such as heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

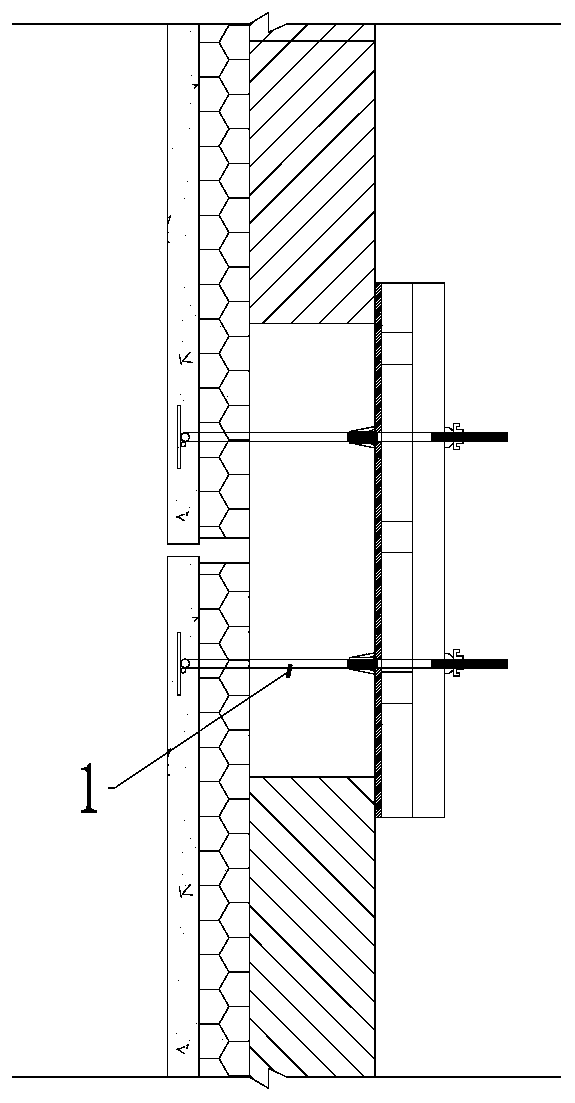

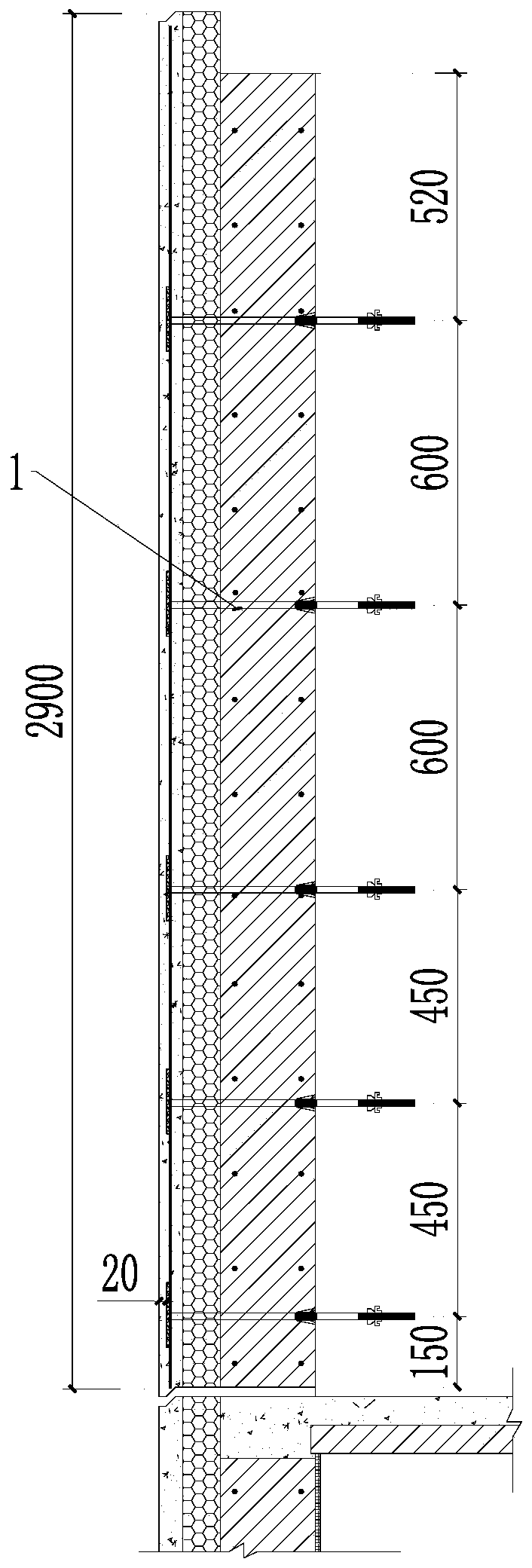

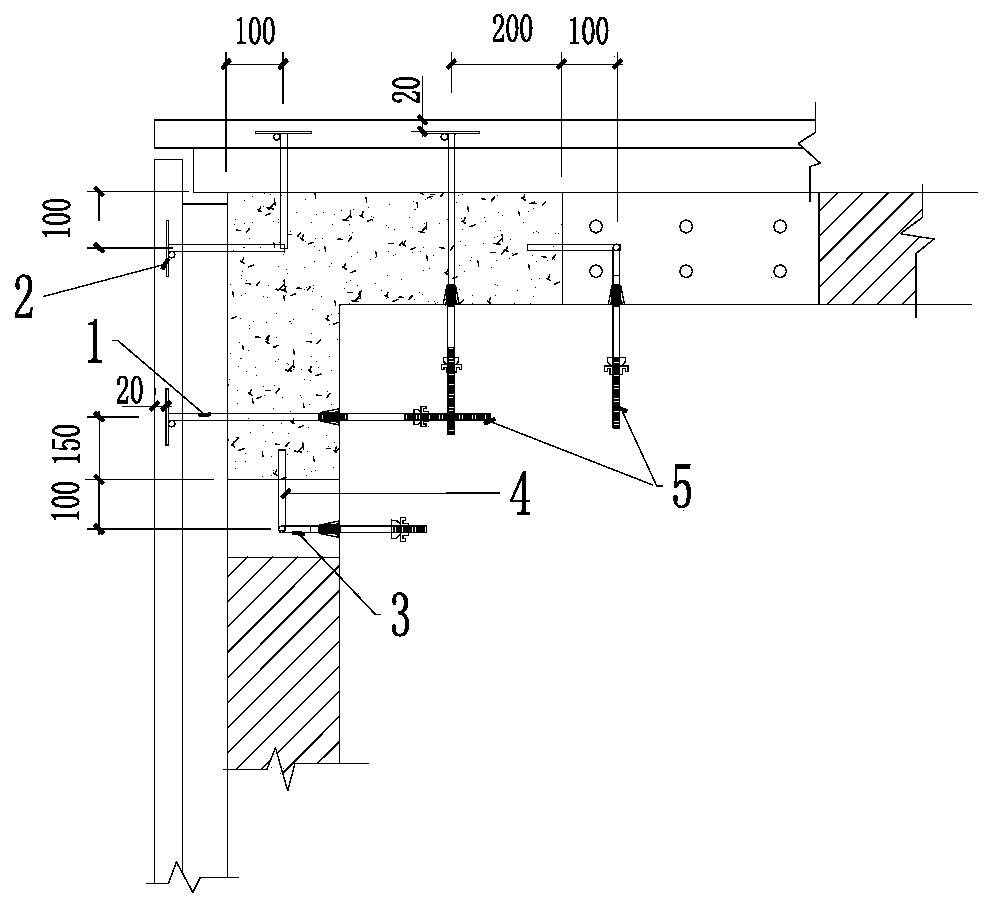

[0027] Attached below Figure 1-5 The construction method of the present invention is described in detail:

[0028] A single-side formwork construction method for the prefabricated exterior wall cast-in-place section of an assembled structure sandwich insulation board, the operation steps are as follows:

[0029] First, make the pre-embedded connectors of the wallboard. The pre-embedded connector 1 is a steel bar vertically fixed on a steel plate; The method is welded together with the steel bar, the size of the steel plate is 100mm*100mm, and the thickness of the steel plate is 5mm.

[0030] Second, when prefabricating the wall panel, the connecting piece 21 is pre-embedded on the outer leaf plate of the poured part of the wall. When the outer leaf plate reinforcement is installed, the specific operation is: the steel plate of the connecting piece 21 is placed on the outer leaf plate reinforcement mesh The outer side is spot-welded with the reinforcement mesh; the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com