Colum angle formwork suitable for fabricated building and construction method of column angle formwork

A prefabricated, formwork technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, and construction, can solve the problems of increased formwork cost, formwork waste, poor pouring quality, etc., to ensure the pouring quality, The effect of ensuring fixed effect and speeding up installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

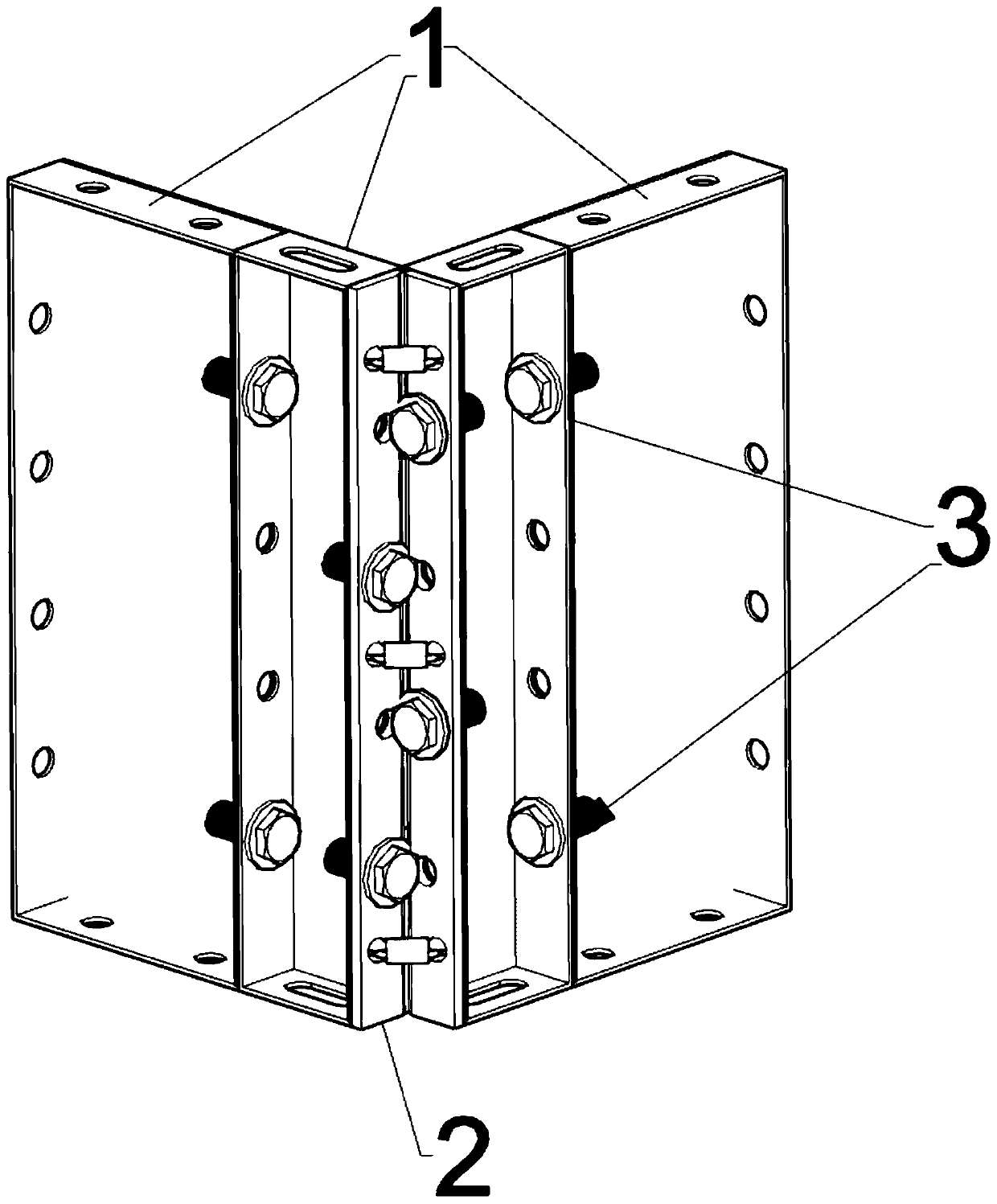

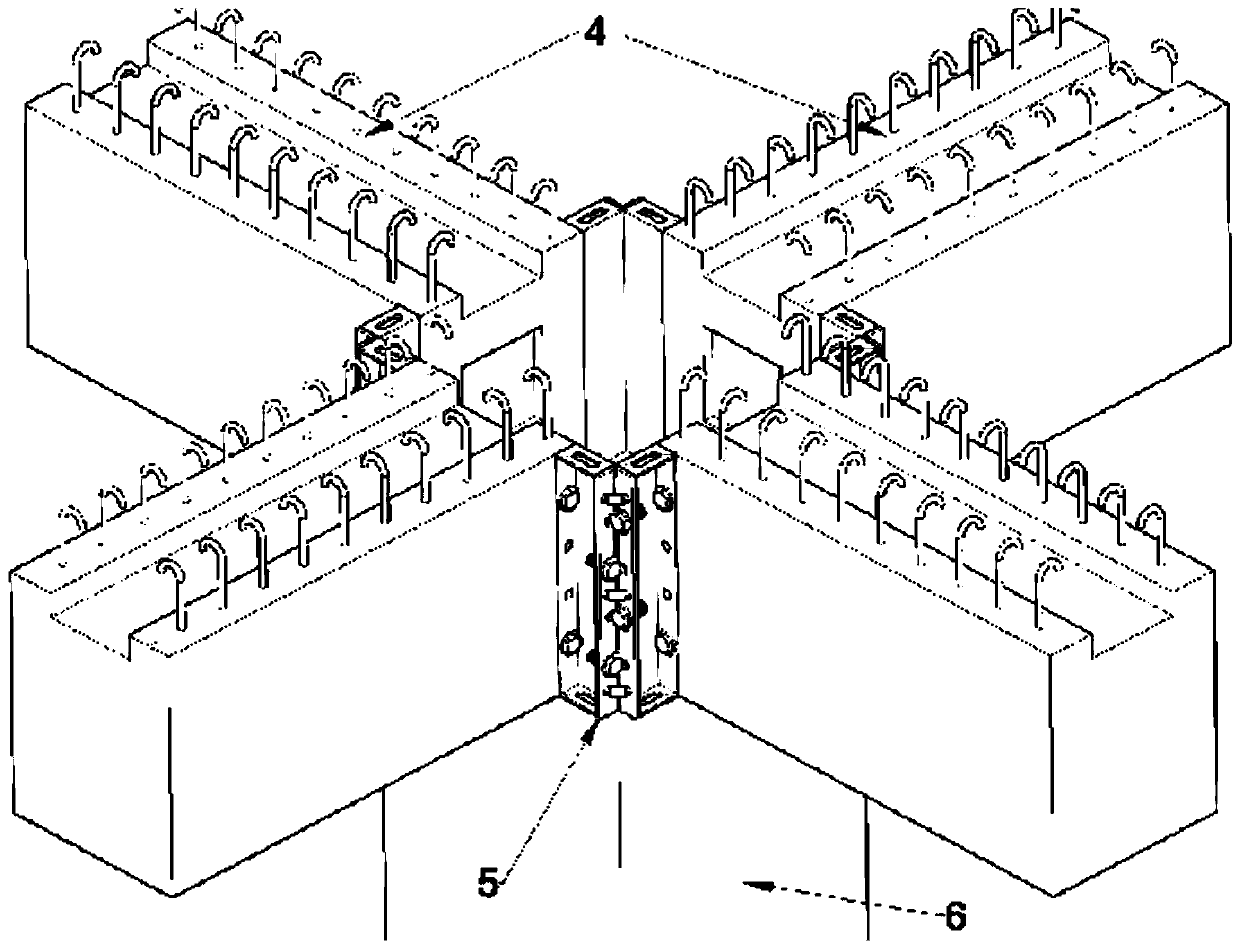

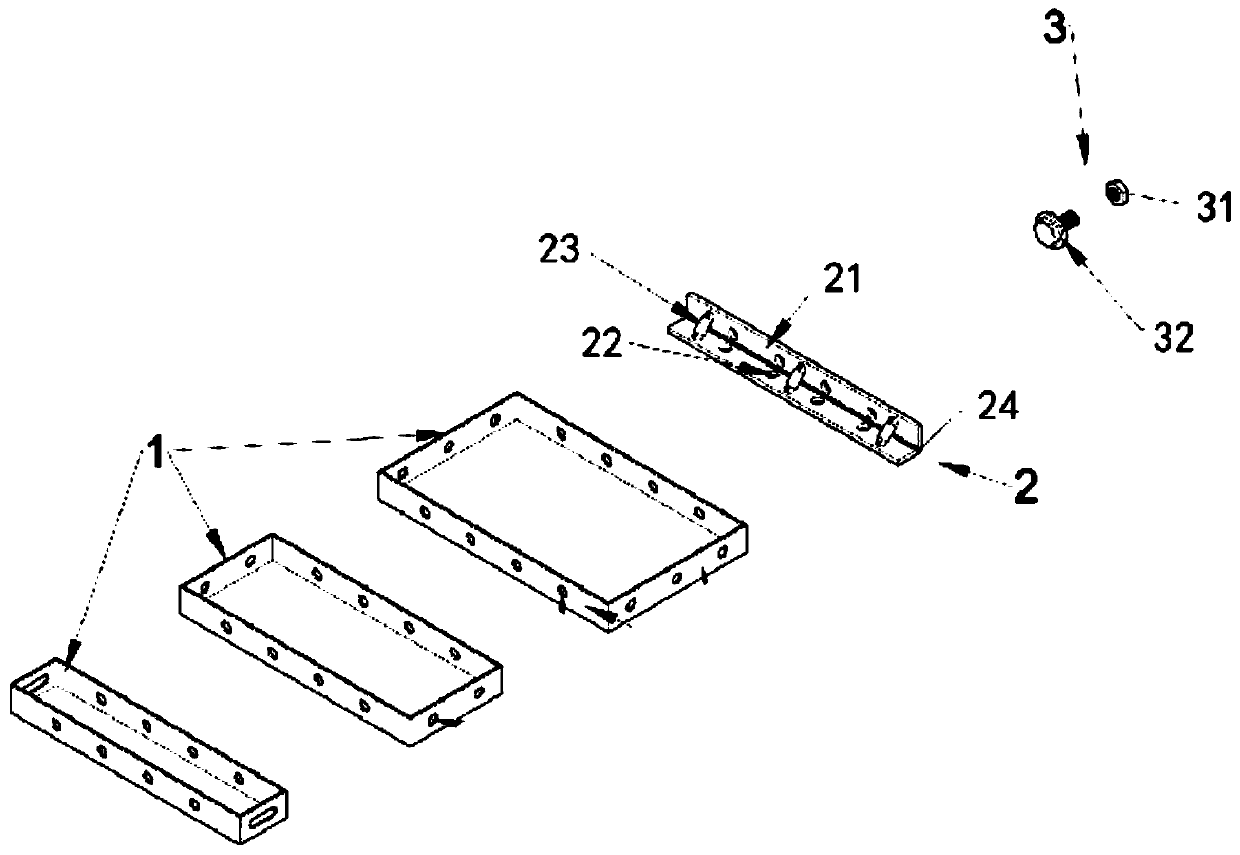

[0028] See figure 1 , figure 2 , image 3 and Figure 4 As shown, the column corner template suitable for prefabricated buildings of the present invention includes a corner connecting plate 21 and a connecting plate 1 detachably connected to both sides of the corner connecting plate 21. The corner connecting plate 21 includes a first hinged joint. The board body 21 and the second board body 22 are connected between the first board body 21 and the second board body 22 with a telescopic piece 23 that controls the angle of the first board body 21 and the second board body 22. The connecting plates 1 on both sides of 21 can be spliced according to the node structure of the project building. Through the selection of the size of the connecting plate 1 and the adjustment of the angle of the corner connecting plate 21, it can be well adapted to the node structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com