Slag stone quick cleaning device for slurry shield machine

A cleaning device and shield machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., to avoid mud leakage, avoid difficult cleaning of slag, and ensure airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

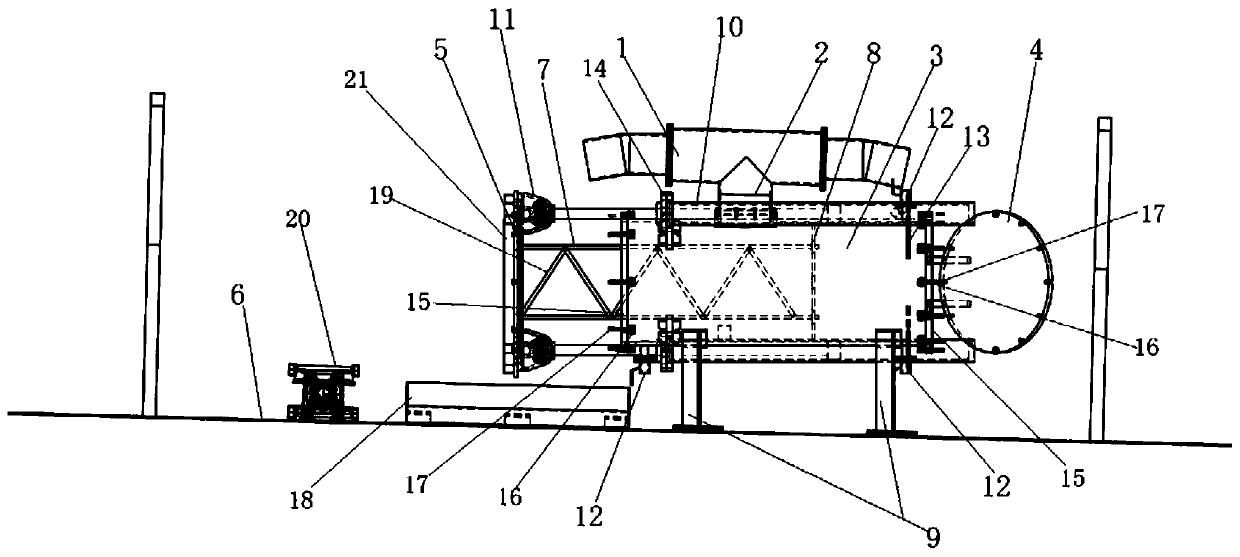

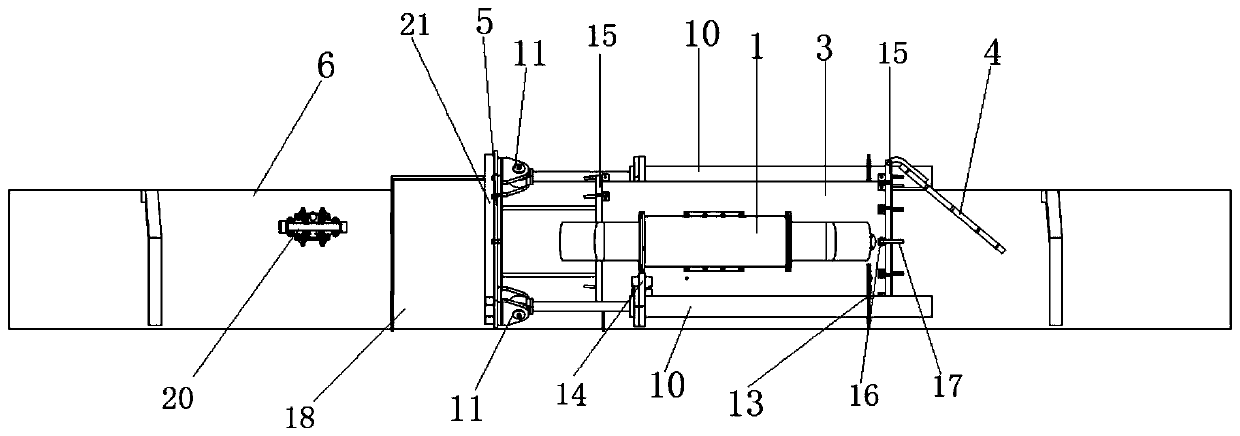

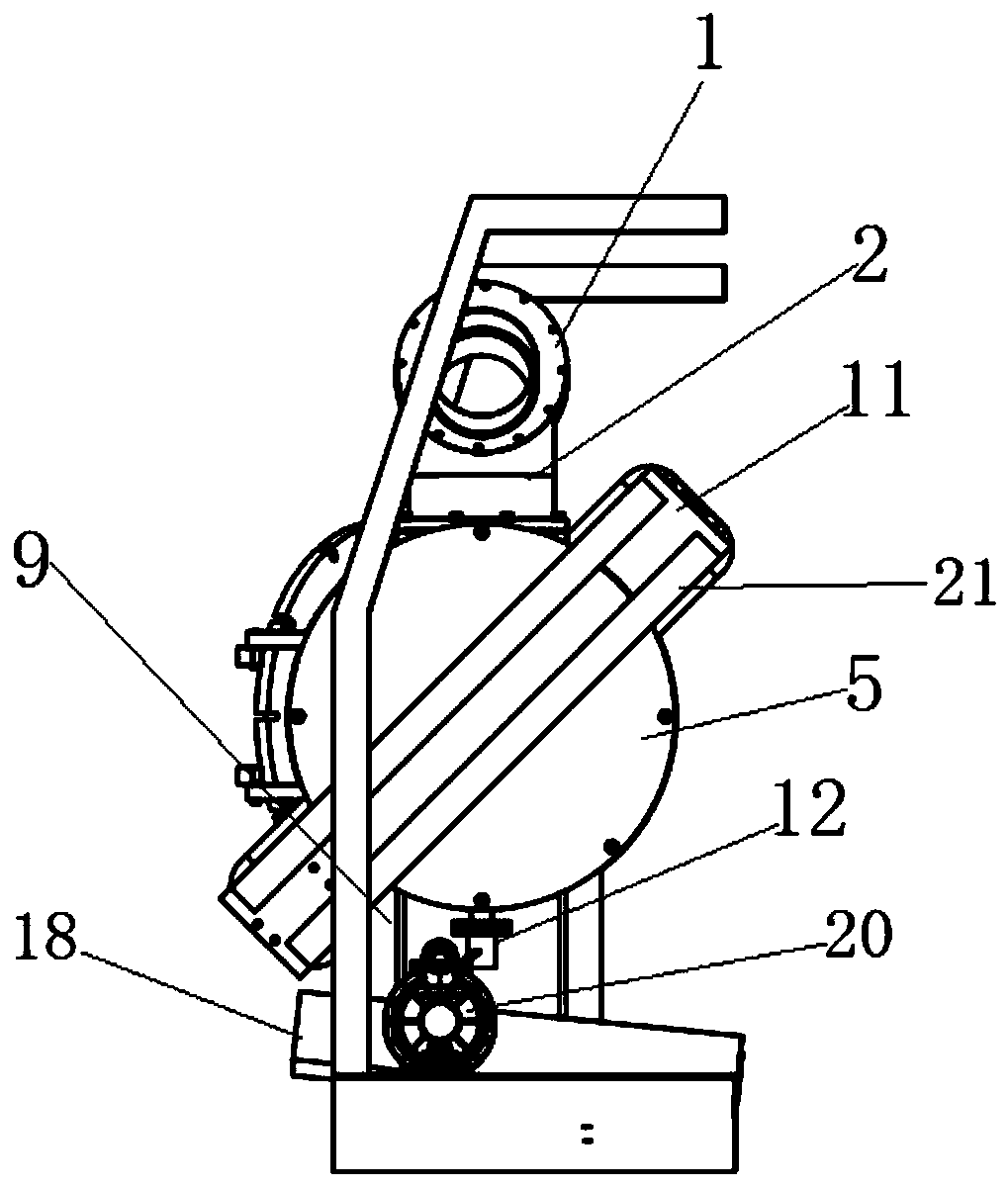

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] combined with figure 1 to attach Figure 4 The best embodiment of the present invention is described in detail; the rapid cleaning device for muddy water shield machine slag includes a cylindrical quarry box 3 installed on the bottom plate 6 of the trolley directly under the mud circulation system slurry discharge pipe 1 of the shield machine , the box wall of the quarry box 3 is provided with a through hole, the through hole is connected with one end of the slurry inlet pipeline 2, and the other end of the slurry inlet pipeline 2 is connected with the slurry discharge pipeline 1 of the mud circulation system of the shield machine , a plurality of jacking cylinders 10 are installed on the box wall of the quarry box 3, and the jacking cylinders 10 are installed along the length direction of the quarry box 3, and the rod heads of the jacking cylinders 10 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com